T

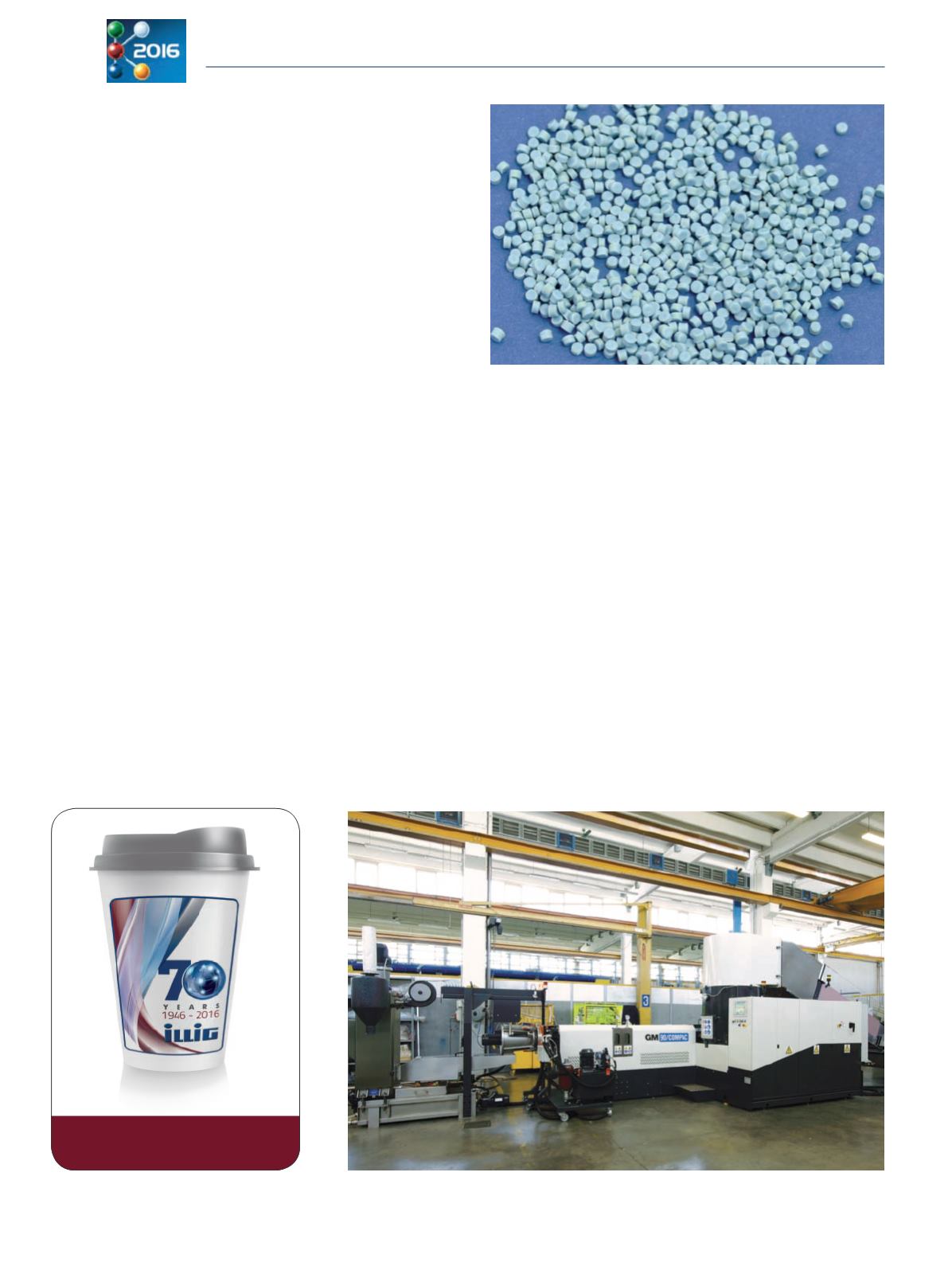

he Italian company Gamma Meccanica S.p.A., which has

specialized in the manufacturing of plastics recycling lines

since 1987, has expanded its business in the Turkish and Ja-

panese markets.

In Turkey Gamma Meccanica completed a contract with a

major customer. The line is a GM125 Compac for recycling of

production waste: PP, PE. This line comprises: Compac feed

with Cutter-compactor, single-screw extruder with degassing,

screen changer and pelletizer. integrated and compact solu-

tion. The COMPAC cutter compactor is equipped with the

ECOTRONIC system for the electronic power control which

provides significant energy savings. Water is no longer used

to control temperature.

ECOTRONIC offering also the possibility of recycling materials

with high moisture. An important feature is the presence of

the feeding screw which guarantees a steady controlled flow

of material into the extruder. The extruder has a degassing sta-

tion with two ports to facilitate the escape of gases produced

during the melting of the material. New extruder screw de-

signs have been incorporated to increase the production out-

puts of the machines. The barrel is heated by the optimum

heaters for this type of application. The exterior casing has im-

proved insulation with ceramic fiber to prevent heat loss and

ensure increased energy efficiency.

The Compac’s feeding screw, together other technical featu-

res that characterize the high quality of the Gamma Meccanica

recycling lines, was fundamental in the customer’s choice.

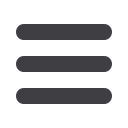

Comparing the laboratory tests on the quality of the granules

Gamma Meccanica:

plastics recycling

GM90 Compac line

Granules recycled of PE + PP

produced and the hourly production of the major Italian and

qualified foreign manufacturers of recycling plants, the

Gamma Meccanica line ensured the best quality recycled gra-

nules and especially a higher hourly production. The line pro-

duces about 10% more than the competitors' lines of the

same size and in a more constant way.

In Japan, a GM90 Compac line for stretch film and packaging

film recycling has been delivered to one of the largest stretch

film recycler.

The screw and barrel of the extruder are designed to process

different types of plastic material: LDPE, LLDPE, PP.

Also in this case, the comparison of the Gamma Meccanica

line with competitors has shown a more constant hourly pro-

duction, it works in a more automated mode and has a very

low energy consumption.

Hall 9, Booth C41

➠ www.gamma-meccanica.itExtrusion International 5/2016

70

www.illig.de