A

t K 2016 in Dusseldorf, ARLANXEO, one of the world’s

largest producers of nitrile-butadiene rubber (NBR), will

highlight its leading position in the supply of NBR powder pro-

ducts and demonstrate the benefits for customers and end-

users.

Visitors at the ARLANXEO stand 6C78 will be able to explore

the company’s broad portfolio from linear to highly pre-cross-

linked powder NBR products, produced by a grinding or spray

drying process for use in various applications. These include

gaskets, brake pads and especially PVC modification, where -

in contrast to standard plasticizers - NBR powder acts as non-

Hall 6, Booth C78

➠ arlanxeo.deFor a long-lasting PVC: The High Performance Baymod N XL 3361

(Photo ARLANXEO, ARPR002)

extractable plasticizer and increases an article’s shelf life.

Luc Briquel, Technical Marketing NBR at ARLANXEO explains:

“In PVC modification typically plasticizers based on phthalic

acid esters like DOP are used to make these polymer blends

softer. However, over time these liquid substances tend to mi-

grate to the substrate surface, leading to shrinkage and har-

dening of the articles.” At K 2016, ARLANXEO will focus on its

word-class NBR powder product Baymod NXL 3361 which of-

fers improved color stability and extrusion properties compa-

red to standard products.

Luc Briquel: “ARLANXEO is constantly investing in Research &

Development in order to identify and develop new areas of

application for NBR. With a total annual capacity of 130,000

metric tons of high-performance rubber, we are able to ad-

vance product performance to meet the needs of the market

and develop tailored solutions for our customers’ business re-

quirements.”

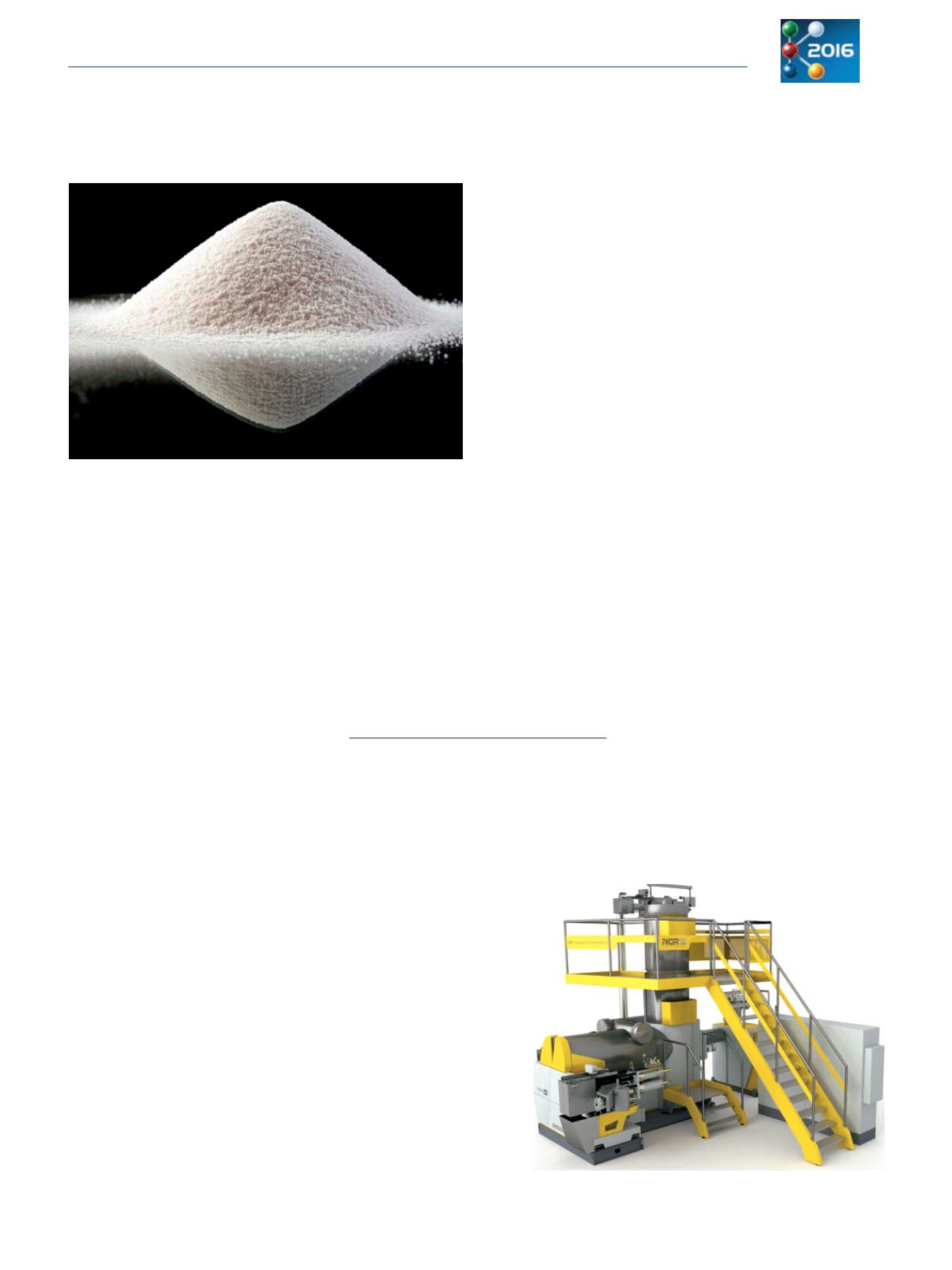

NGR:

S.M.A.R.T. DIALOG and P:REACT

enable permanent monitoring

T

he Austrian provider of recycling-solutions, Next Genera-

tion Recyclingmaschinen GmbH, displays the PET Improve-

ment Equipment P:REACT now with S.M.A.R.T. DIALOG to

fully control, monitor and data-log the decontamination per-

formance, especially for Food Grade applications.

PET-Improvement with P:REACT exceeds highest

safety standards

The liquid phase of the PET in P:REACT with a high surface/vo-

lume ratio of the liquid PET, together with applied vacuum, al-

lows harmful contaminants to be easily removed. Scientific

third party tests, as well as the FDA approval for 100% food

contact prove, that the LSP-Process (Liquid State Polyconden-

Extrusion International 5/2016

65

ARLANXEO:

leading position NBR powder products