ZUMBACH:

extruded pipe and hoses

under tight control

Material savings thanks to measurement

and control of eccentricity and wall thickness

The versatile high-tech ultrasonic system WALLMASTER offers

application-specific solutions for measuring and monitoring

wall thickness. The measuring data processor with touch-

screen display gathers data and QC fully automatically.

In combination with ultrasonic UMAC® scanners and various

ODAC® diameter measuring gauges as well as with error de-

tectors, the measuring and monitoring scale can be expanded

to outside and inside diameter, statistics, SPC and processor

communication.

Using Zumbach’s WALLMASTER measurement and control sy-

stems, manufacturers can economise their expenditure of raw

materials. The ROI is achieved within a few months. The use of

these systems also allows reducing considerably the start-up

time.

Optimized measurement

of monolayer synthetic pipes and hoses

WALLSTARTER – the low-cost processor solution for UMAC®

ultrasonic eccentricity and wall thickness measuring is tailored

to the requirements of the measuring and monitoring of mo-

nolayer synthetic pipes and hoses.

New ultrasonic scanners for flexible diameter adjustment

This novel construction (pat. pend.) is going to be one of the

exhibition's highlights: the transducers can be either indivi-

dually or simultaneously adjusted to the best possible measu-

ring position within seconds. The scanners cover an outside

diameter up to 180 mm and represent a smart and simple so-

lution for full non-contact, in-line eccentricity and wall thick-

ness measurement of tubes, hoses

and cable jackets.

High-end Non-contact Profile and

Shape Measurement, Combining

Laser and CCD Technology

In-line cross-section measure-

ment of plastic and rubber pro-

files of any kind

The PROFILEMASTER systems

from Zumbach represent an accurate and economical solution

for measuring and monitoring dimensions or even the com-

plete cross-section of profiles and pipes made of plastics or

rubber - throughout the manufacturing process.

All relevant dimensions such as width, height, angle and radii

are added together to form the full cross-sectional picture.

Linear Sensor Technology allows cost effective, synchronous

multi-axis Measurement of Diameter and Ovality in Extrusion

Processes

Unique measurement technology for products

up to 200 mm outside diameter

• A new product line with 2-coloured LED light sources allo-

wing simultaneous scanning in each axis (XY*) and thus trou-

ble-free measurement even with product vibration

• Integrated extraneous light filters prevent occurrence of

measurement errors that to date seemed unavoidable

• Perfect performance even with reflective surfaces thanks to

the use of different colour lighting for each measurement axis

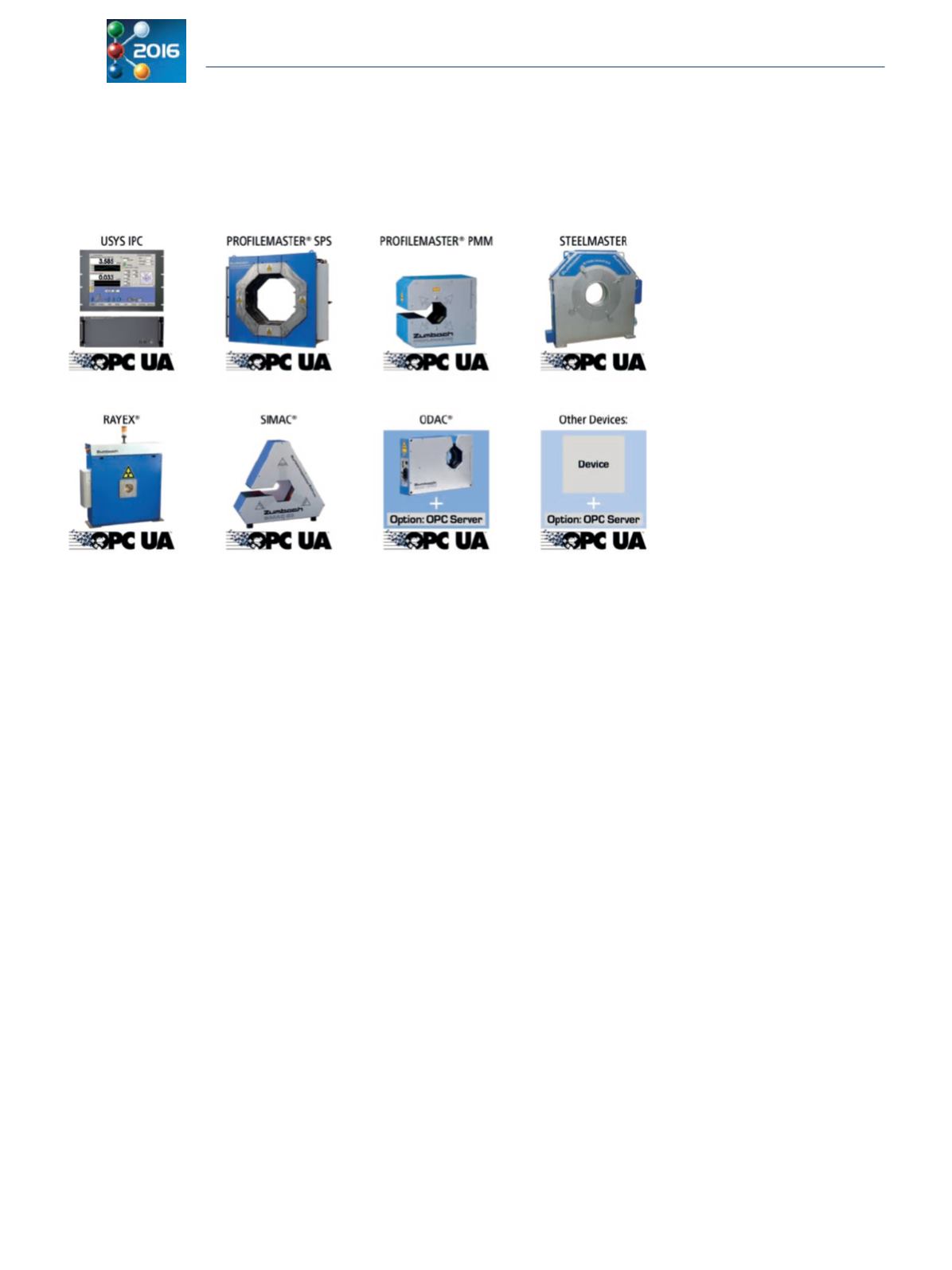

OPC UA: Transparent data management –

simple monitoring in real-time

• ZUMBACH equips its powerful instruments with the recog-

nized OPC UA standard. With this key technology, measure-

ment solutions provide easy, scalable and secure information

exchange with different systems in the production line – Plat-

form and manufacturer-independent data exchange.

Selection of available Zumbach

instruments with OPC UA

Hall 10, Booth E41

➠ www.zumbach.comExtrusion International 5/2016

74