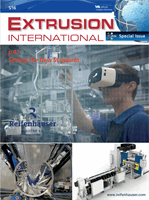

the other hand, article demoulding and subsequent handling

can be continued in the outer station while a new article is

being vulcanized in the clamping unit. The realization of con-

stant processes is therefore given and completes the 360° so-

lutions by DESMA with all technical and economic aspects in

the production chain.

Realizing big possibilities of saving material

. It is still the ma-

terial where the biggest savings can be achieved. For this pur-

pose, DESMA offers the innovative cold runner systems. The

new FlowControl E-Drive cold runner with servo-electrically ac-

tuated shut-off nozzles enables the filling process of each

nozzle to be triggered individually via the mould internal pres-

sure sensor and the cavities to be evaluated during the vulca-

nizing cycle. The article can be fitted with an individual QR

code with assigning all process and setting parameters inclu-

ding the mould, other aids and the compound batch by using

the integrated laser station. The further advanced ZeroWaste-

ITM pot for runner-free direct injection also is equipped with

a mould internal pressure sensor in order to control the trans-

fer process precisely.

DESMA and Industry 4.0

. The development of the innovative

product range SmartConnect 4.U allows production proces-

ses to be realized in a more flexible, efficient and resource-

friendly way by applying intelligent networking. The new

systems make a higher plant and machine uptime, a more

transparent and improved product quality or piece cost ori-

ented production efficiency possible. A claim which the mar-

ket leader DESMA of course lives up to – in the light of

increasing customer requirements and dynamic market deve-

lopments.

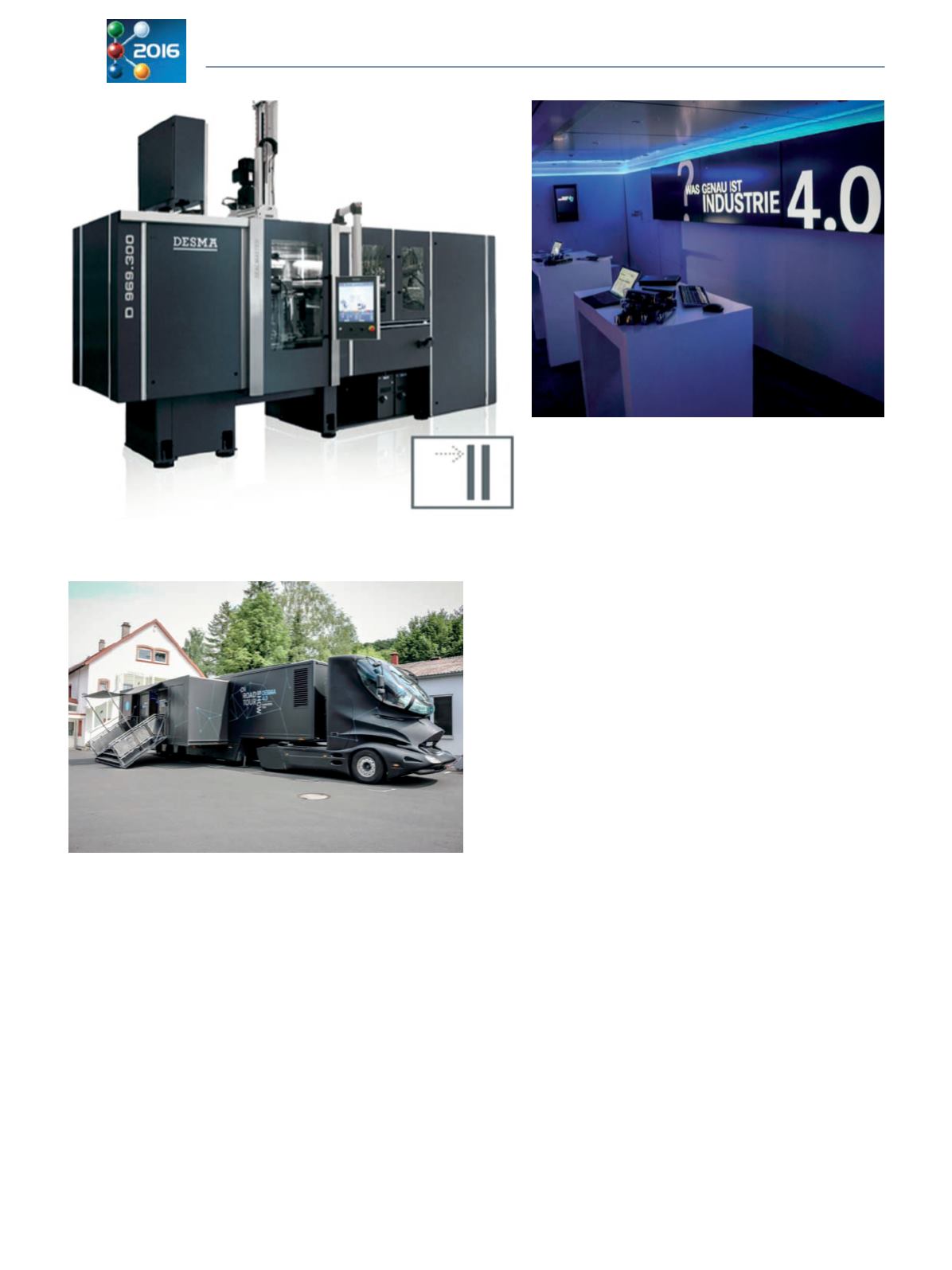

The final spurt of the DESMA Inspiration Tour 2016

. On the oc-

casion of the newly developed Industry 4.0 solutions, DESMA

started a roadshow across Europe. A 40-ton truck designed

by Colani and packed full of presentation technology and new

4.0 compatible products was sent to stop in 16 countries.

From April until October it is on its way marked by the motto

‚DESMA Inspiration Tour 2016‘ and covers more than 16,500

km. The final highlight will be the K 2016 in Düsseldorf where

the truck can be visited outside at FG 16.2.

Hall 16, Booth F56

➠ www.desma.bizExtrusion International 5/2016

76

D 968.250 ZO (S3)

Roadshow-Truck