chine can be configured to account for the properties of dif-

ferent feed materials. For easy to shred materials, for instance

foils, high speeds are preferable in order to attain a high

throughput. Solid semi-finished plastic products, full plastics

as well as thick or heat-sensitive materials are shred at lower

speeds.

The blades of the rotor shaft can be utilized on both sides

and are rotated with minimum manual effort. The counter-

blade can be adjusted. This ensures that the cutting gap is

➠ www.bhs-sonthofen.deExtrusion International 5/2016

34

Recycling machines from BHS-Sonthofen:

When taking over AMNI Maschinenbau GmbH in 2013,

BHS-Sonthofen extended its product portfolio of recycling

machines by adding shredders and granulators with cutting

technology. Today, the company offers a wide range of shred-

ders, granulators and crushers with impact and shear crus-

hing alongside cutting technology.

always optimally calibrated. It can also be used on two sides

and replaced within the shortest time.

The design engineers have also attached considerable im-

portance to high availability in the context of adapting the

machine to various requirements: The screen basket can be

changed within a few minutes. This is advantageous when

destroying files, for example, if different protection classes

are applicable in successive batches.

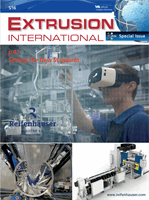

Design of the Universal Shredder (NGU):

Up to 150 individual blades (yellow) are

mounted on the circumference

of the rotor shaft

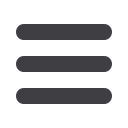

Operating principle of the Universal Shredder (NGU):

The hydraulically driven slide presses the feed material

against the rotor, where it is cut and shred at the stator.

After attaining the desired size, it falls through the screen

basket downwards out of the machine