Extrusion International 5/2016

31

CONEXTRU GmbH

|

Klosterstraße 19, A-3011 Tullnerbach

|

info@conextru.eu|

www.conextru.euYou need a new tool

for your new

pipe product?

Ɣ TXLFN DQG DW ORZ FRVW ±

VSHFLDOO\ PDGH IRU

\RXU UHTXHVW

Ɣ LQ PRQR RU PXOWL OD\HU

or for coating in your

FXUUHQW SLSH SURGXFWLRQ

CONEXTRU

ENGINEERING FOR EXTRUSION

<RX ZDQW WR PRGLI\ \RXU H[LVWLQJ WRROV WR PXOWLOD\HU DQG

IRU LQWHUQDO SLSH FRROLQJ WR PDNH D QHZ SURGXFW"

Then

CONEXTRU GmbH

LV WKH SDUWQHU IRU \RX ±

WKH PRVW H[SHULHQFHG FRPSDQ\ LQ SLSH WRRO GHVLJQ

The development of new tools for pipes is our

profession and passion – for more than 25 years.

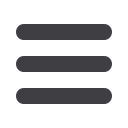

ring values a comprehensive trending and statistical infor-

mation. If we assume that a line, where tubes are produced

with an outer diameter of 400 mm and a wall thickness of

22.7 mm, runs at a line speed of 0.66 m/min, the machine

operator receives accurate measuring results already after ca.

15 min, if there is at first a cooling trough to pass of ca. 10

m length for stabilization of the extruded tube.

Installation in the extrusion line

As temperatures have no influence on the measuring result

when using millimeter wave technology, the system can be

installed for hot measurement as well as at the cold end of

the line for final quality control. Immediately after the first

cooling, the system provides precise information. In addition,

the technology covers the entire range of plastics such as PE,

HDPE, PP, PA6 and PVC.

Applications

The millimeter wave technology is suitable for the measure-

ment of any kinds of plastic tubes with a diameter from

120mm to 2,500mm and larger that are for example used

for conducting water, gas, chemicals and oil. Particularly in-

teresting is the use of the system for the extrusion of PVC,

which is one of the most widely used materials for tubes in

the construction and transport area. Also for PVC tubes with

thick walls the system provides precise measuring values.

Another area of application is the measurement of multi-layer

tubes and curved surfaces. During production, there is the

risk that the melt that leaves the tube tool flows down as a

result of gravity and thus negatively influences the tube wall

thickness distribution. This “sagging” is identified by the

measuring method. Via a display and control device the ma-

chine operator immediately receives information on the pro-

duction process to take actions if necessary.

The measuring values of the CENTERWAVE 6000

are numerically and graphically displayed at the

processor system ECOCONTROL

➠ www.sikora.net