Extrusion International 5/2016

32

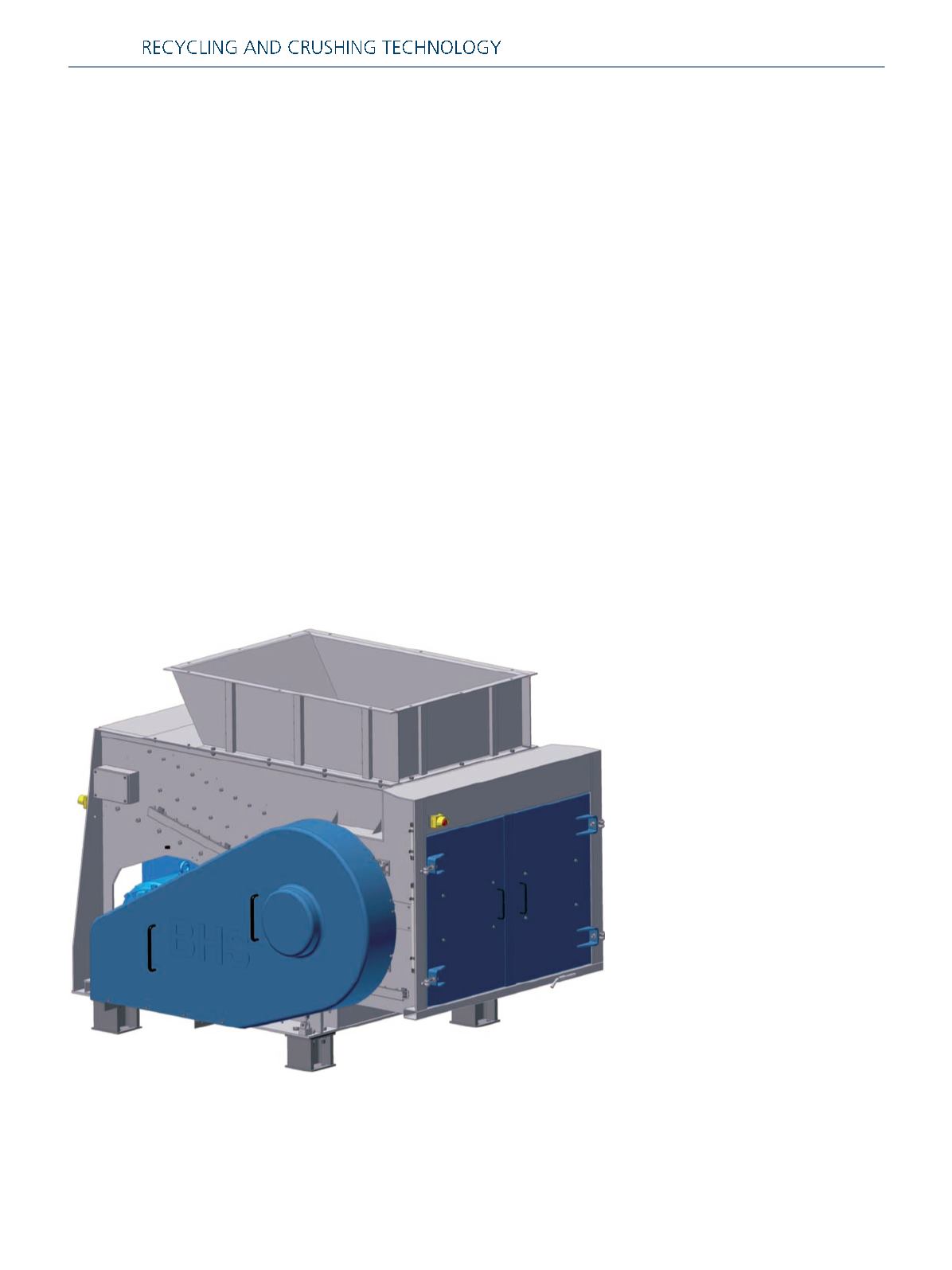

New Universal Shredder –

completely redesigned

BHS-Sonthofen unveiled the new Universal Shredder of type NGU at IFAT 2016. This new product

extends the company’s range of single-shaft shredders by a machine designed for conventional recy-

cling facilities and use in the manufacturing industry. It is generally suitable for all materials that can

be cut and is characterized by a sturdy design, easy operation and high availability. The new Univer-

sal Shredder is available in several versions – for example with a screen perforation of 30 mm –

for a throughput of 6.5 t/h and more.

The new Universal Shredder of type NGU is designed for

shredding almost all materials that can be cut, such as paper,

files, data media, wood, plastics or packaging

The new Universal Shredder of type

NGU shreds the loaded material to a

size between 20 and 100 mm. It can be

used at conventional recyclers for shred-

ding various materials, for example, for

cutting paper and paper rolls, for de-

stroying files and data media, as well as

for almost all plastic

parts, leather and textiles, residual

wood, cables or parts made from PET.

It is also suitable for production compa-

nies that generate large volumes of

waste. In this field of application, it size

reduces the material so it can be pro-

cessed further at the same facility or to

facilitate transportation to the treat-

ment company. A typical application in-

volves plastic barrels, which are

collected centrally at one location in a

company and then shred in order to re-

duce the transport costs for further pro-

cessing.

Dennis Kemmann, Managing Director

of BHS-Sonthofen GmbH, has comple-

tely redesigned the machine with his

team: “Our aim is for our customers to

achieve the lowest possible processing

costs per ton. Before getting down to

the design, we asked many users what