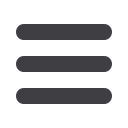

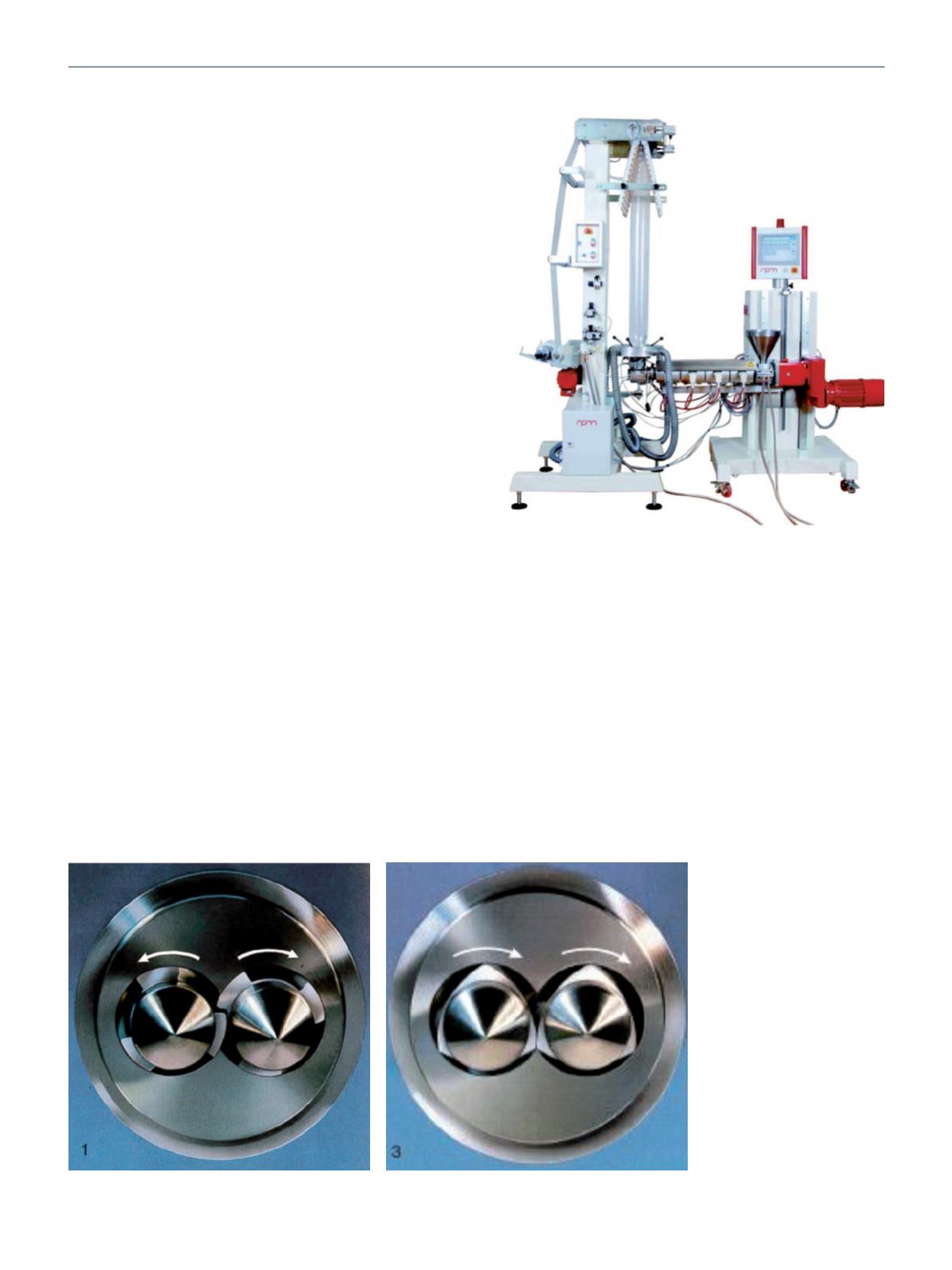

During the 1970s, the production trend moved towards syn-

chronized extruders – counter-rotating extruders were hardly

used any more at that time. The different systems’ manner of

working is compared in Figures 5.1 and 5.3. In the synchro-

nized system, the synchronized intermeshing principle and

the higher screw revolution speed creates a higher shear ef-

fect in the polymer and pigment products. I should mention

at this point that these developments didn’t simply happen in

large bursts, it was a continuous process.

Due to the advancement in the field of extrusion, for exam-

ple, through special elements for the screw with very high

shear and dispersing effects, masterbatch color selection be-

came more and more versatile and increasingly higher in

terms of pigment concentration.

We know that you are very experienced in working

with companies around the globe, especially with firms

in Russia and Eastern European countries. What can you

tell us about this from personal experience?

TENNER

: Over the years, the export situation changed in that

an increasing number of machines were exported for ma-

sterbatch production. Three countries are particularly note-

worthy here: the USA, Russia and Romania.

In the 1970s, we established a subsidiary in New Jersey (USA)

for Leistritz – and it is still very successful in the market to this

day.

In the former Soviet Union, we supplied machines to Akade-

mograd, which lies about 20 km from the center of Novosi-

birsk. Basic research in 20 elementary scientific fields was

carried out here.

Another Eastern Bloc country to which we delivered a large

number of machines was Romania. Color masterbatches and

processing batches for various applications were manufactu-

red there. Our partner in Romania was Elena Ceau escu, the

president’s wife. Their great desire was to make plastics pro-

Fig. 4: LAB film blowing system (Source: Noris Plastic)

Fig. 5.3): Synchronized system

(Source for both images: Leistritz AG)

➠ www.norisplastic.deExtrusion International 5/2016

27

Fig. 5.1): Counter-rotating & intermeshing system

cessing popular in the country. Among other things, they also

wanted to create many new jobs.

Looking to the future, it can be said with great certainty that

there are still many interesting possibilities in the raw mate-

rials modification field, i.e. Masterbatch/Compounding.

These include the replacement of metal and wood through

plastics and many other related applications.

Mr. Tenner, thank you very much for your interesting

story. We wish you all the best!