Davis-Standard:

Global Advantage™

D

avis-Standard LLC will exhibit the depth of its Global Ad-

vantage™in extrusion and converting technology during K

2016 in Düsseldorf.

Technology being shown includes examples of extruder, feeds-

crew, die, unwind, and control system advancements as well

as the company’s innovative dsX™ technology and extensive

aftermarket capabilities. As an added benefit, Davis-Standard’s

team will host visitors at ER-WE-PA’s Erkrath facility for equip-

ment demonstrations. Following are highlights from Davis-

Standard’s K display:

Extruder with QSE Adapter

– This 3.5-inch (90mm) exrtruder

has preferred features such as computer designed feedscrews,

electrical barrel heating with air-cooling for each zone, and

simplified electrical installation. Mounted on the extruder will

be a QSE (Quick Screw Exchange) adapter for fast screw

changes without disturbing the downstream melt path.

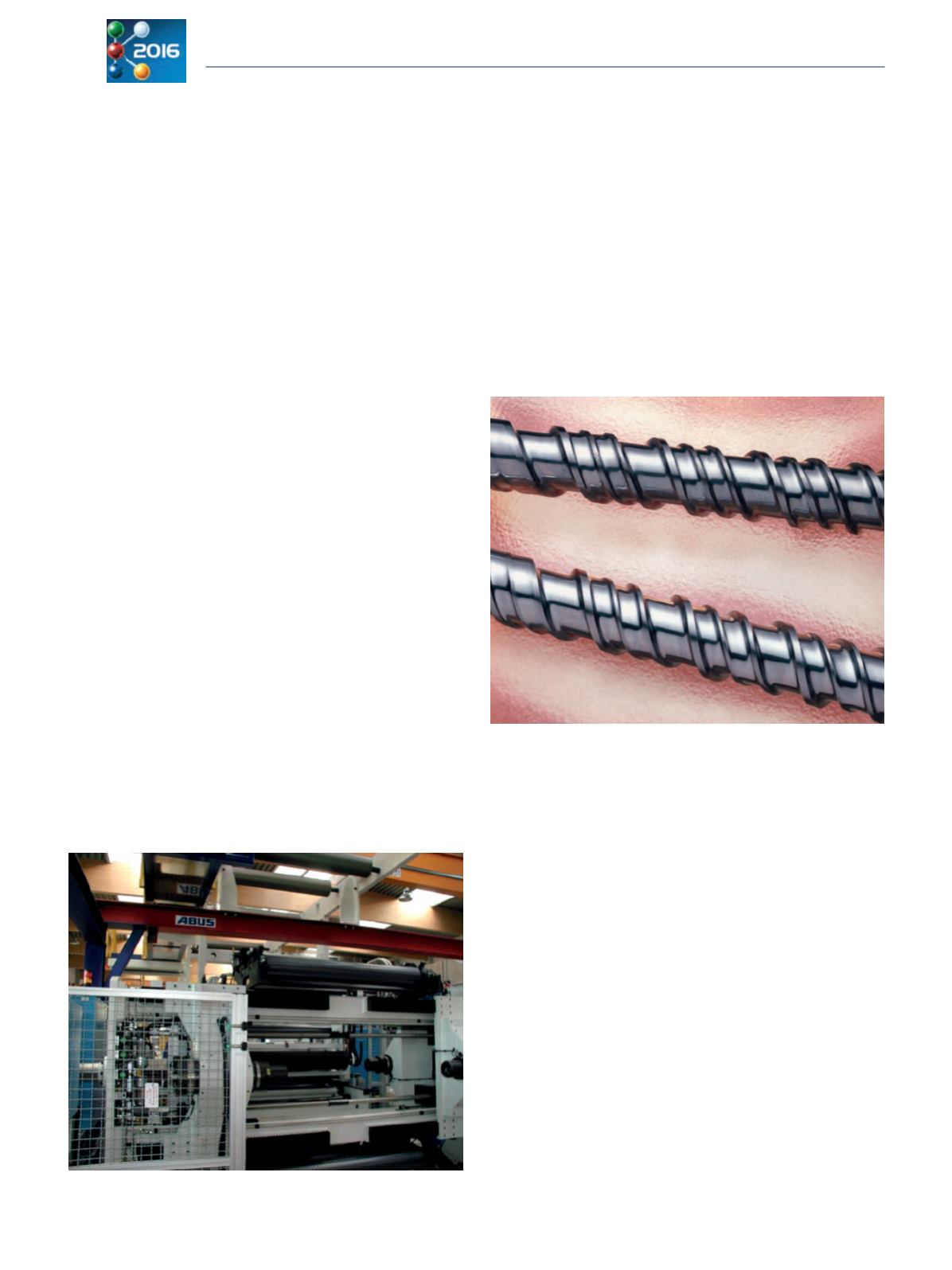

High Speed Film & Foil Unwind

– Designed for thin substrates,

this two-position turret unwind is designed for an 800 meter-

per-minute splice speed for sensitive webs such as aluminum

foil at 6 µm. Unique splice unit controls and safety standards

create excellent reliabilty for high-speed splicing of complex

webs.

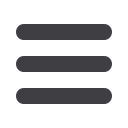

Feedscrew and Die Displays

– Davis-Standard is a global leader

in feedscrews and die designs for improved processing effi-

ciency. Multiple feedscrew designs and finishes will be shown

in the booth at the K Show, as well as a seven-layer die stand

from Davis-Standard’s Gloucester Engineering product line.

Also being promoted will be the new die rebuild services of-

fered by Davis-Standard Limited in the United Kingdom.

dsX™Technology

– This popular line of extrusion coating, cast

film and blown film equipment offers processors advantages

in price, performance and delivery. Each system is engineered

for greater up-time, increased productivity and reduced waste,

and backed by Davis-Standard’s 24/7 global support network.

Aftermarket Capabilities

– Davis-Standard’s ability to service

equipment for nearly every extrusion and converting applica-

tion, including non Davis-Standard brands, is one of the com-

pany’s greatest advantages. This includes an extensive spare

parts inventory, timely 24/7 customer service, global technical

capabilities, rebuild and retrofit services.

For customers interested in visiting Erkrath, Davis-Standard will

offer transportation to and from the Düsseldorf Fairgrounds.

The transportation schedule will be available at the show. ER-

WE-PA will demonstrate new horizontal winding technology

and discuss extrusion equipment for a variety of applications.

Customers will also learn more about Davis-Standard’s regio-

nal service team for the European market, which provides cus-

tomers with a quick response by service technicians and a

large stock of available spare parts. Service and support for

Davis-Standard’s line of control systems enables customers to

upgrade PLC, drive and mechanical systems on thousands of

existing installations, including non Davis-Standard brands.

Hall 16, Booth A43

➠ www.davis-standard.comExtrusion International 5/2016

64