battenfeld-cincinnati:

“Driven by innovation”

T

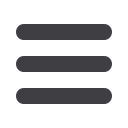

he new single screw extruder solEX NG 75 for the production

of PO pipe will definitely be a highlight at the booth. Based

on solEX series, which is already established in the market, the

NG series offers a completely re-designed barrel-screw combi-

nation. With this, battenfeld-cincinnati sets new benchmarks in

the market in terms of output and energy consumption. The ad-

vantages of the “Next Generation” are lower melt temperatures,

optimized, con-stant pressure build-up and reduced mainte-

nance costs with sig-nificantly higher outputs compared to the

previous models. Thanks to the lower drive energy and reduced

energy losses, energy costs can be decreased by up to 15%.

“With the design of the new NG series we again prove our in-

novativeness. We have succeeded in developing an

extremely powerful and energy-efficient processing

unit that has not yet been seen on the market in this

form,” em-phasizes Grant Flaharty, battenfeld-

cincinnati’s Chief Sales and Marketing Officer.

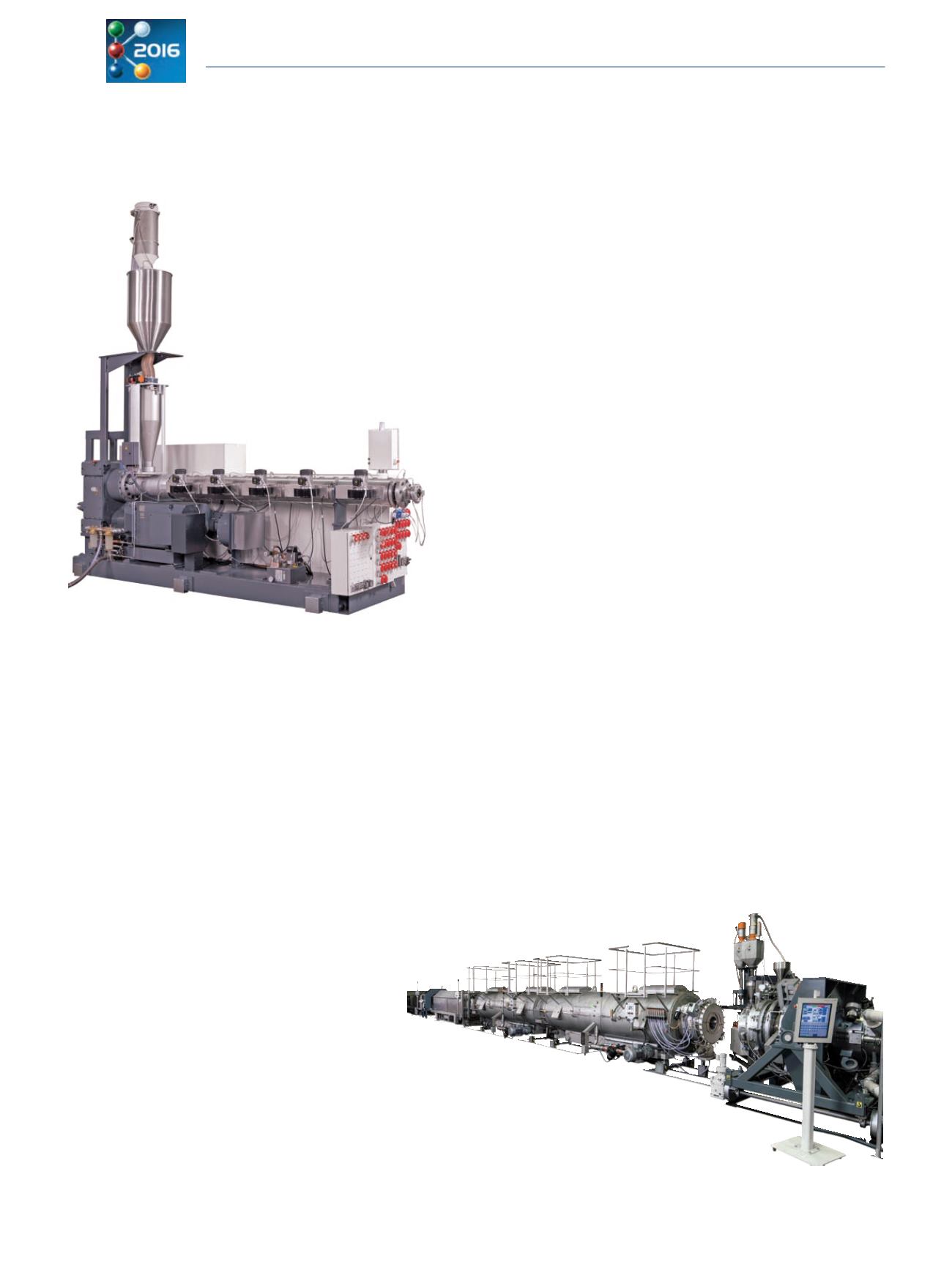

In combination with the new PO extruder, the ma-

chinery manufacturer will show another innovation:

the Fast Dimension Change (FDC) system. At the

booth, three components will be shown – the pipe

head, the calibration sleeve and the vacuum tank.

With the FDC pipe head, die changes are largely un-

necessary, thanks to an adjustable melt gap. There-

fore, it can be used uni-versally for a wide pipe

diameter range. For the first time, an adapter for

the outer layer has been integrated in the adjustable

The solEX NG extruder series features a completely

new processing unit that offers a multitude of advantages,

such as a lower melt temperature and energy costs reduced

by up to 15%

The FDC (fast dimension change) system enables pipe dimension

changes during production. Three components of the system will

be shown at battenfeld-cincinnati’s booth: pipe head, calibration

sleeve and vacuum tank

Extrusion International 5/2016

42

die, offering the shortest purging times currently available, for

example during a color change. Instead of a rigid calibration

cylin-der, the FDC calibration sleeve consists of movable ele-

ments that can be adjusted to almost every diameter, but do not

leave any markings on the final product. Finally, the 1.5 m long

FDC vacuum tank has scissors lift tables that allow the adjust-

ment to every height with servomotors. A unique flexible and

above all easily adjustable sealing technology ensures a secure

sealing of the vac-uum tank.

Multi-Touch roll stack reaps success worldwide

“We have proven in the past years that we are optimally pre-

pared for the growth market packaging sheet with our high-

speed ex-truders and the Multi-Touch roll stack which is unique

in the indus-try. Customers all over the world have decided in

favor of this technology and we have installed numerous sys-

tems worldwide,” Dr. Henning Stieglitz, Chief Technology Offi-

cer, is pleased to report about the market success of

thermoforming sheet extrusion equipment. This is why the ma-

chinery manufacturer will show a Multi-Touch roll stack at its

booth – this time in a XXL-version. Multi-Touch roll stacks work

with a combination of a roll stack with two rolls for pre-calibra-

tion and three, give or seven rolls in post-calibration. So they

produce stress-free sheet with thickness toler-ances of

≤

1% at

high speeds. The newly developed XXL roll stack shows excep-

tionally high performance. Outputs of more than 3 t/h can be re-

alized depending on the width and thickness of the sheet while

at the same time there are no compromises in sheet quality.