Of course, a complete extrusion line also requires a matching

con-trol technology. Here, too, flexibility is key. A new control

with a modern 21.5” full-HD multitouch display in landscape

format will be presented at the booth. Not only does it offer

a novel operating and visualization concept, but also addi-

tional features that are a perfect tool for processors in the re-

alization of industry 4.0 agen-das.

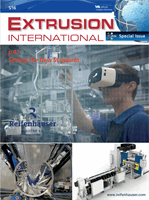

Flexibility is paramount for twin screw extruders

The machine portfolio at the booth is completed by several

twin screw extruder exhibits for pipe and profile production.

The high-light are two models from the completely newly de-

veloped conical twin screw extruder series that offers an ex-

ceptionally wide appli-cation range thanks to a newly

designed processing unit. Apart from the processing technol-

ogy, the complete machine was rede-signed and optimized

based on experiences in the field. “With this series we take

into account, among other considerations, the in-creasing re-

quirements of window profile producers. The machines offer

a wide throughput range, as well as the possibility of pro-cess-

ing diverse formulations,” emphasizes Dr. Stieglitz in speaking

of the new series’ advantages. In addition to their flexibility,

the extruders convince with gentle melt processing and easy

handling.

At K 2016, two extruders from the new series will be shown:

a conEX NG 65 in stand-alone execution and a conEX NG 54

in a co-extrusion set-up. The latter is mounted on a pedestal

and com-bined with a twinEX 93EP as main extruder. This new

pedestal solution is suitable for a variety of set-up options and

can be ad-justed individually to the location’s requirements

thanks to its modular system. The set-up on display offers

processors highest flexibility and an optimal price-perfor-

mance ratio. In addition, the conEX NG 54 will feature an en-

ergy-saving kit.

This includes a synchronous motor and a variety of additional

features that signifi-cantly reduce the extruder’s energy con-

sumption.

Grant Flaharty feels certain: “With the different exhibits from

our wide product portfolio for the extrusion industry, we are

present-ing modern, energy-efficient solutions that will meet

the future requirements of the industry as well.”

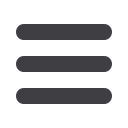

An XXL version of the successful Multi-Touch roll

stack will be shown at the booth

The conEX NG series features a newly developed

processing unit and is extremely flexible and energy-efficient.

Both a stand-alone execution and a co-extrusion execution

mounted on a pedestal will be exhibited

Hall 16, Booth B19

➠ www.battenfeld-cincinnati.comExtrusion International 5/2016

43

19. - 26.10.’16

Halle 10 - J39

gwk Gesellschaft Wärme Kältetechnik mbH

Scherl 10 · D-58540 Meinerzhagen

Tel. +49 2354 7060-0

Fax +49 2354 7060-156

info@gwk.com·

www.gwk.comPERFECT

COOLING

AND

TEMPERATURE CONTROL

.

Worldwide

.