Extrusion International 3/2016

36

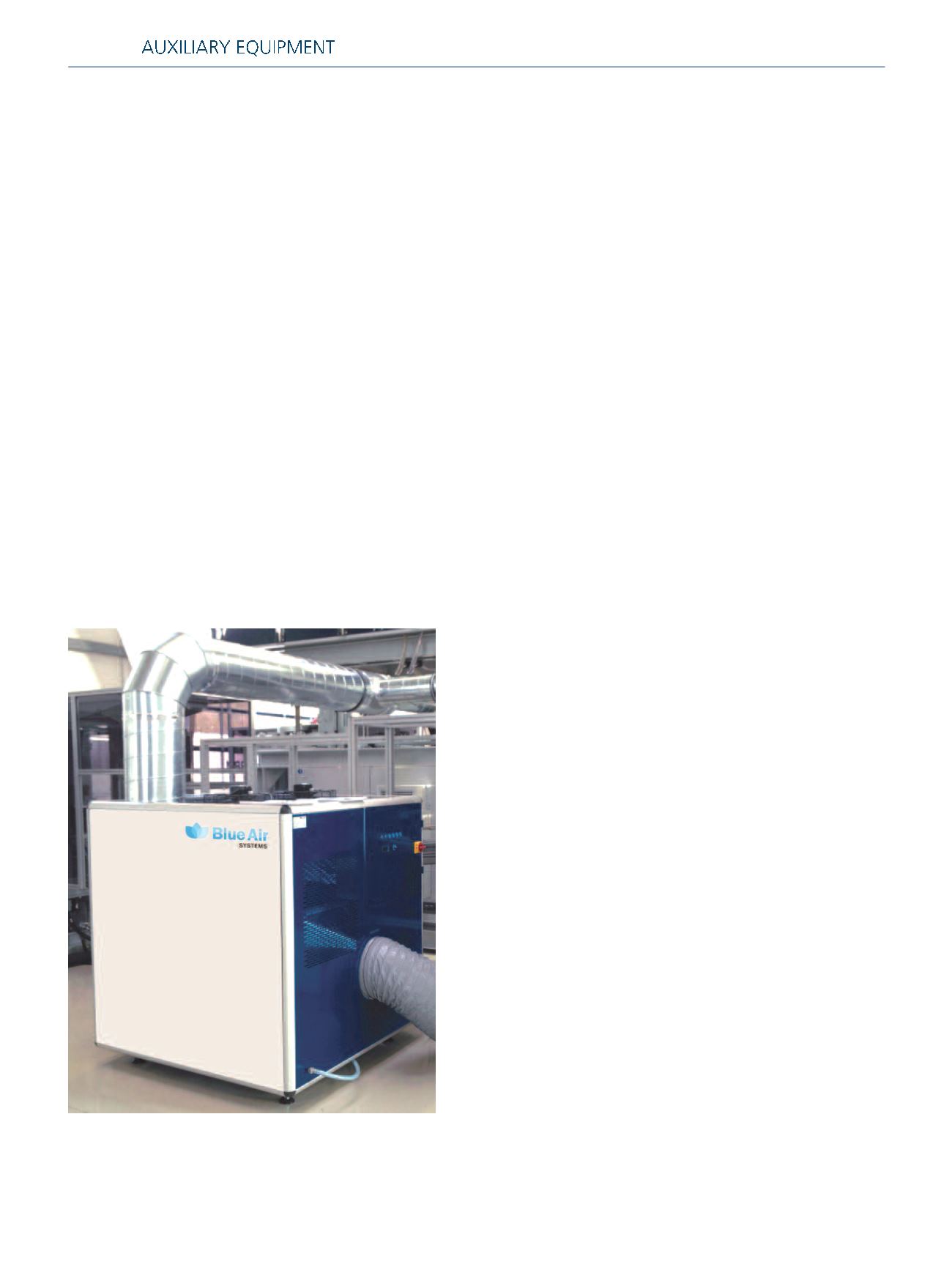

Waterless DMS-technology

for energy-efficient mould

area dehumidification

Injection moulding, thermo forming and blow moulding without condensation is possible.

Blue Air Systems’ basic range of MSP-Dehumidification units (with process air volumes between 1.000

and 10.000 Nm³/h) was complemented with the new DMS series (Dry Mould System), a dehumidifier

which works without the need for chilled water. An enclosed production area is supplied with dry air

with a dew point of 4°C (39,2°F). The DMS dehumidification units with process air volumes ranging

from 500 to 3.500 N³/h are now available.

T

he mould dehumidification units MSP are used mainly for

supplying dry air to a central dehumidification system. The

DMS series are specialized to be used for single production

machines (up to 3 units). At the K 2016, the DMS system for

high demanding injection moulding, extrusion blow moulding

or thermo forming applications will be demonstrated to the

trade visitors. As inventor of this game-changing technology,

Blue Air Systems has spent three intensive years developing,

testing and improving the system. The DMS units provide

year-round, condensation-free production conditions, inde-

pendent of ambient conditions, without the need for chilled

water needed for pre-cooling. This energy-efficient technol-

ogy guarantees the users of injection, blow moulding or ther-

moforming machines to run the shortest possible cycle times,

therefore guaranteeing higher production output. The DMS

series has been installed in various climatic areas, proving its

performance. A number of references prove their efficiency

and effectiveness.

The phenomenon of condensation on tempered moulds

When the surface temperature of an object sinks below the

dew point of the ambient air, condensation builds on this ob-

ject. This problem especially occurs on moulds of plastic pro-

cessing machines that are cooled by chilled water. The cooling

time, usually the longest part of the cycle time and one of the

most sensitive steps of the manufacturing process is an im-

portant figure that influences the cost factor of the entire pro-

duction process.

Dehumidification with the DMS unit (Dry Mould System) for

packing, PET pre-form production and many other highly

sophisticated applications