Extrusion International 3/2016

32

www.amut.itT

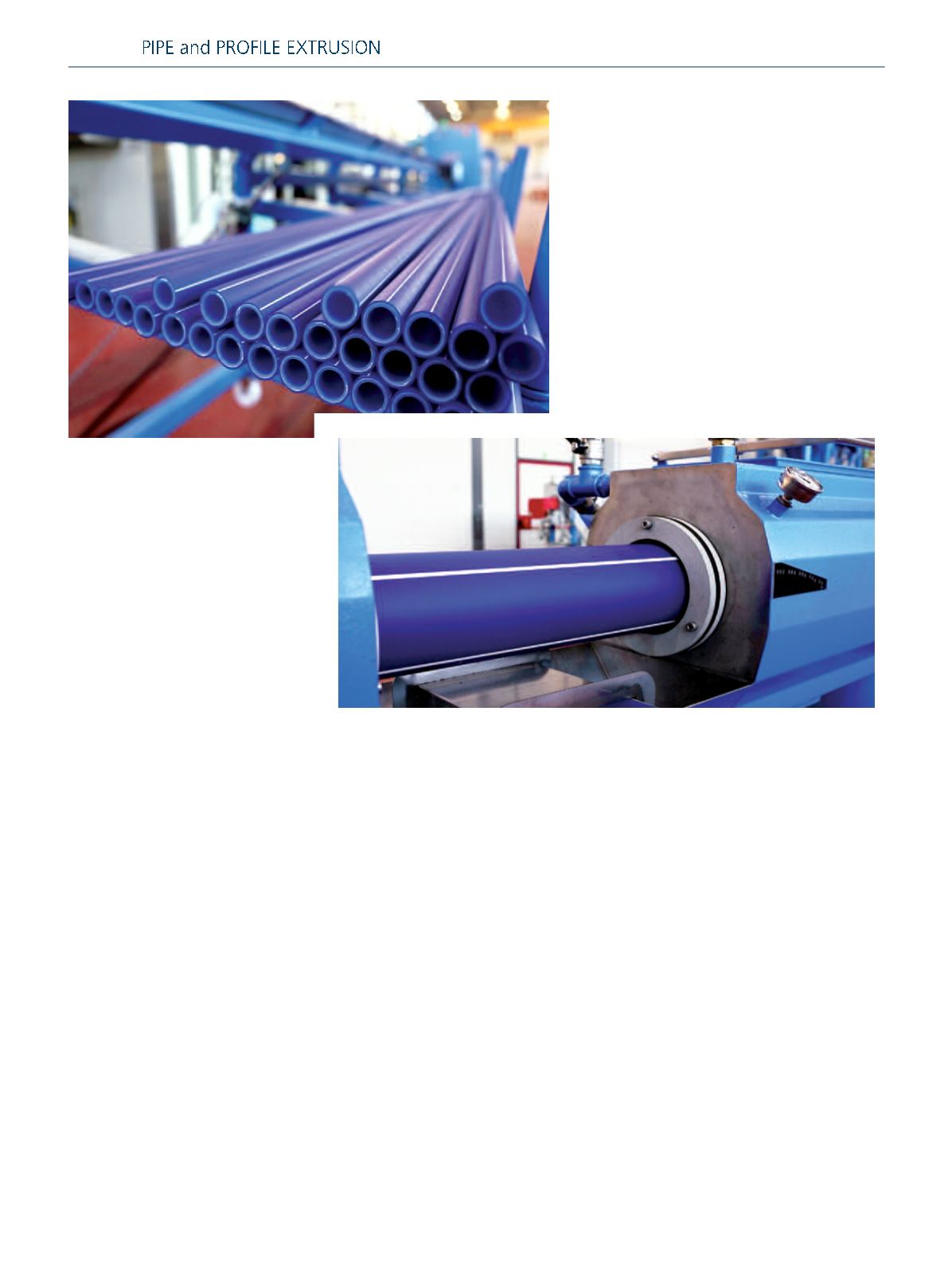

he line has a range of diameters from 16 to 200 mm, with

SDR 6–11, and the new design 3-layer co-extrusion head

allows a configuration A-B-A or A-B-C with external coloured

stripes.

Main Technical Features

The co-extrusion line configuration consists of four extruders:

EA60 Single Screw Extruder - (A) Internal/External Layer

EA75 Single Screw Extruder - (B) Middle Layer (Glass Fi-

bres/Mineral Filler)

EA60 Single Screw Extruder - (C) External Layer

A20 Single Screw Extruder - External Coloured Stripes

The extruders are fed by gravimetric system for a better con-

trol of the output and each screw and barrel undergo a spe-

cial antiabrasion treatment to process properly the glass fibres

or the mineral filler.

The production changeover, according to the chosen diame-

ter, is very quick because the whole re-tooling concept is de-

vised to minimize times and manual operator intervention.

The gauging measurement system continuously controls all

the parameters during the production process to ensure a

top quality pipes. The software manages the different reci-

pes.

Extrusion Line for Multiplayer

Pipes Production

AMUT continues to improve the

technology of lines producing PP pipes

with glass fibres and mineral filler

(calcium carbonate or barium sulphate).

The pipes extruded with this techno-

logy are used for hot water piping and

soundproofing drainage piping.

The glass fibres improve the elastic and

mechanical properties of the material,

the reduction in pipe thickness, main-

taining the same resistance level, and

the thermal expansion (less joints are

required). The quality of pipes is defini-

tely enhanced.