Extrusion International 3/2016

30

The leading edge

that always connects

In 2013, Greiner Extrusion developed RED.TOOLING, the tooling system focusing on productivity,

profile quality and economization. In line with this achievement and in order to complete the

RED.LINE-system product range, post-co-extrusion has also been developed further with the creation

of RED.PCE. The RED.PCE unit is compatible with all other Greiner tooling types.

The leading rdge through user optimization

The clear benefits when using RED.PCE are user optimization

on the one hand and increased quality during the production

process on the other. The multiple use of PCE dies for differ-

ent profile geometries allows for a huge saving potential. The

mounting system includes a tank with integrated mounting

bars. It is continuously adjustable along its length and can be

operated from both sides. Mounting of the end suction and

sealing plates is fairly straightforward. Cylindrical safety in-

serts in the sealing plates prevent process interruptions and

make the start-up process easier at the same time. The short

set-up time has a positive effect when changing the dies, as

the heater block with PCE guide stays on the adjustment

block. Up to four PCE gaskets including adjustment blocks

that are also accessible from both sides can be fitted onto

the mounting bars.

The leading rdge through increased quality

Using RED.PCE allows the production of gaskets using joined-

in and joined-on extrusion. The joined-in gaskets can be ex-

changed and easily recycled. The joined-on gaskets stand out

through optimum adhesion. Two variants of joined-on gas-

kets can be processed during RED.PCE production: firstly,

with the well-known heated-air function and secondly, using

the recently developed variant with the pre-heater rail.

With the heated-air variant the welding area is heated with

an air jet. For this purpose, additional equipment is required

such as the heat extension, leister hot air blower, and control

box.

The second variant with the contactless pre-heater rail is

called RED.PCE plus. With the RED.PCE plus system the join-

ing surface of the carrier profile is heated with the pre-heater

rail and the welding surface is extended with an additional

blade.

After this, the gasket is directly joined onto the carrier profile.

This production process distinguishes itself through optimum

adhesion and exact positioning to the profile.

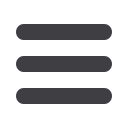

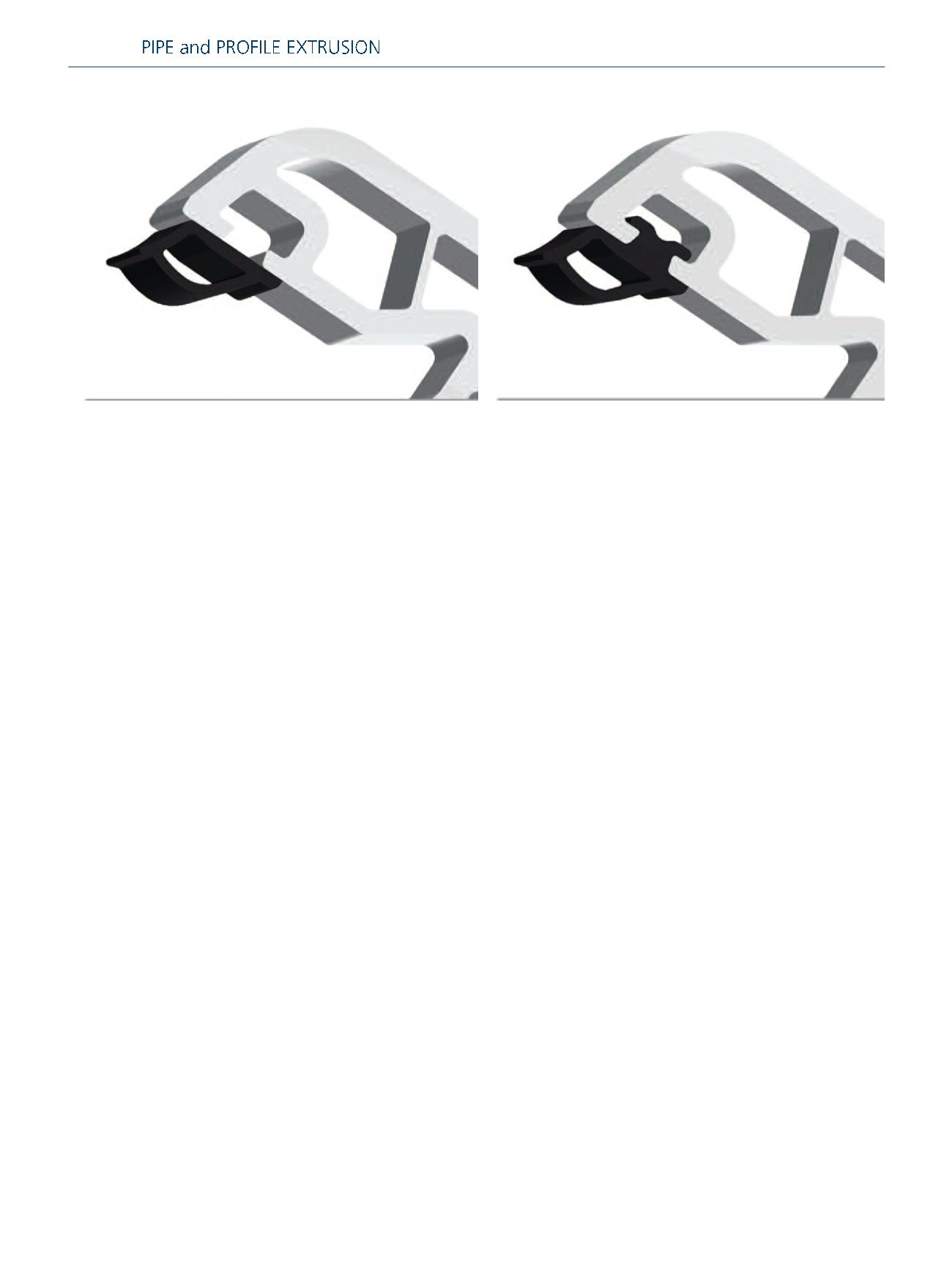

gaskets joined on by extrusion

gaskets joined in by extrusion

www.greiner-extrusion.at