用可靠的方法按需要生产LFT组合料

Chinaplas 2016:

Tailored LFT Compounds the Reliable Way

在今年的中国国际橡塑展

上,ProTec高分子工艺有限公司将集

中展示通过拉挤方法生产LFT(长纤维

增强热塑性塑料)组合料的技术以及新

一代ProTec翻转式反应器。固态后缩

聚(SSP)反应器可以完美地应用于

改善可流动塑料原料的性能。 例如:

经过造粒的聚酯(PET,PBT,PEN

等)以及尼龙(如PA6和PA6.6)的后

缩聚。这些改性后的物料可以加工成产

品,例如瓶子、纤维、用于光导及轮胎

帘子线和空气囊的工业用丝、复合纤维

材料、过滤用织物或者无纺布。当进行

注射模塑加工时,采用带有沿着粒子长

度方向的纤维增强的LFT混合料,将能

够使生产出的部件既具备高强度,又有

重量轻的特点,并且部件的表面质量非

常好。长度约12mm的LFT的纤维,对于

进一步加工来说是理想的。

ProTec Polymer Processing's focus at

this year's Chinaplas will be on the

production of long-fibre-reinforced

thermoplastics (LFT) by pultrusion

and on the new generation of Pro-

Tec tumble reactors. These SSP (so-

lid-state post-condensation) reactors

are ideally suited to improving the

properties of flowable plastics. Ex-

amples include the post-condensa-

tion of pelletised polyesters (PET,

PBT, PEN etc.) and nylons such as PA6 and PA6.6.

These "upgraded" materials are then for example

converted into bottles, fibres and industrial yarns

which are required for optical waveguides, tyre

cords and for airbags, fibre-composite materials, fil-

ter fabrics or nonwovens. When injection moulded,

LFT compounds with fibre reinforcement along the

length of the pellets result in components which

combine high strength and light weight with very

good surface quality. LFTs with a fibre length of

around 12 mm are ideal for further processing.

50

2016中国国际橡塑展

Extrusion Asia Edition 1/2016

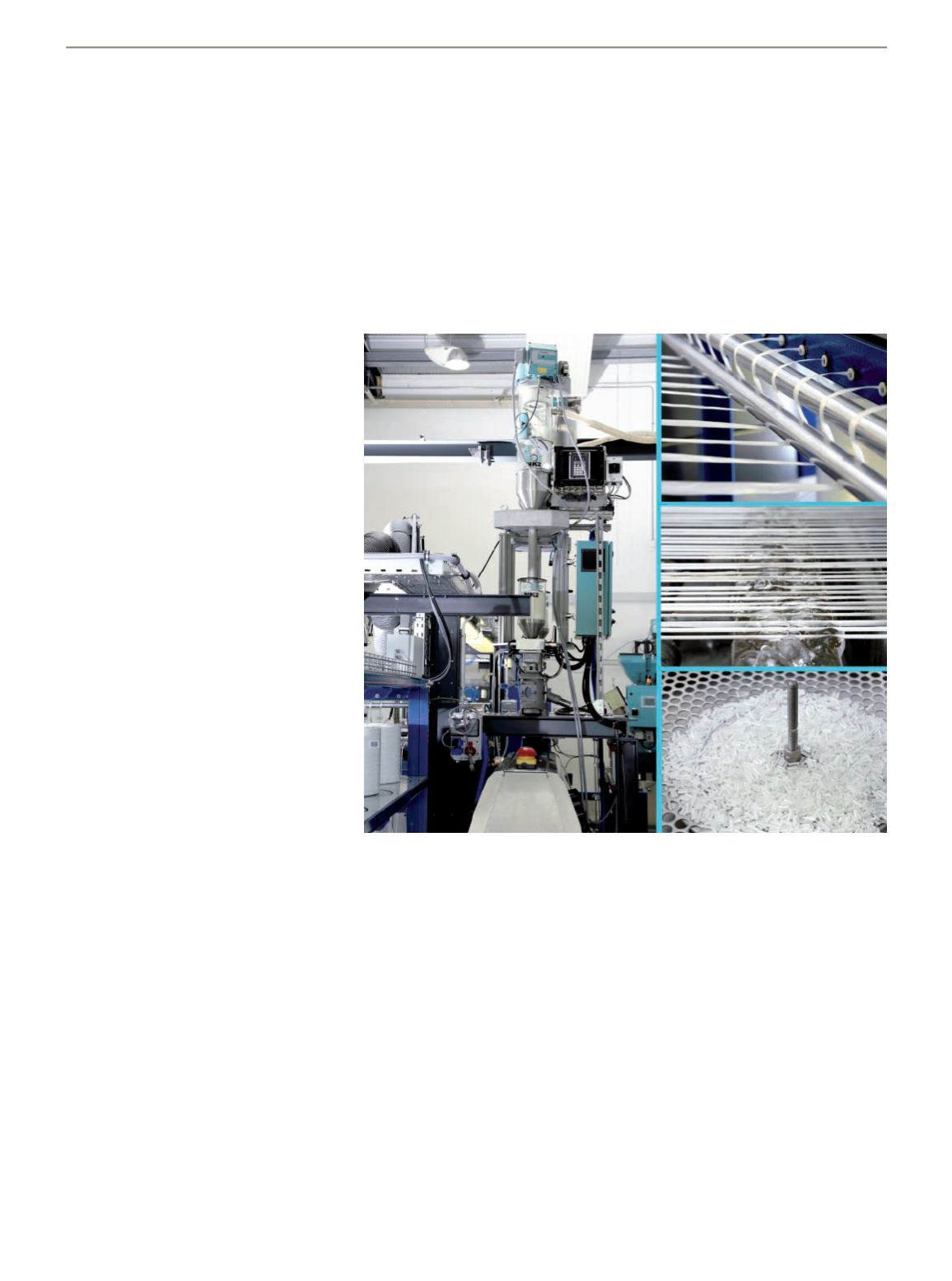

Flexible, versatile LFT technology

ProTec's LFT technology is suitable for producing a wide range

of materials with differing levels of fibre reinforcement and ma-

ny different polymer matrix materials which may also be direct-

ly compounded during LFT manufacture. Even the difficult pair-

ing of carbon fibres with PP can be reliably processed. ProTec's

headquarters in Bensheim (Germany) has a versatile cutting

edge pultrusion line for application-specific customer testing

and basic process and materials development.

A keystone of the line is a high-performance compounding ex-

truder equipped with a SOMOS

®

Gramix S gravimetric dosing

system capable of accurately dosing and mixing up to nine

ProTec的LFT拉挤技术生产高等级长纤维增强粒子,作为基体的高分子材料范围广

泛,可使用各种各样的增强纤维。

这一技术同样能够可靠而灵活地调节基体材料的性能。

ProTec's LFT pultrusion technology produces high grade long-fibre-reinforced

pellets with a wide range of polymer matrices and huge variety of reinforcing

fibres. This technology also permits reliable and flexible adjustment of matrix

properties (Photo: ProTec Polymer Processing)