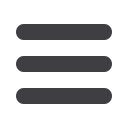

节架用于悬挂一只或两只大袋。用于两只大袋的调节架,可

以是手动或气力开关自动,同时,填充料位控制带有报警信

号。一旦第一个袋子装满时,气动开关会切换到装填第二个

袋子。 当变换物料之前,管道系统应抽吸干净,以避免不同

的物料的混合。抽吸空气通过悬浮的过滤管或筒式过滤器进

行清洁。筒式过滤器有很高的清洁效率,并能自动清洁。

Getecha的一体化解决方案,设备涵盖了从粉碎到抽料

输送直到大袋装袋的全部过程。无论是成型的泡罩包装、糖

果盒嵌件或者谷类杯盖都是由热成型工艺制造的,德国公司

Getecha所提供的设备,能够保证无缝联接热成型设备,物

料实现了经济的循环利用。

2016年中国国际橡塑展:W4 K25

This can be done with pressurized or suction operation – Gete-

cha offers both options.

With pressurized operation, the granulated material is transpor-

ted from the granulator via a fan wheel through the pipeline

and on to cyclone and BigBag. With the suction operation, the

granulated material is "pulled" through the pipe system via a

medium-pressure blower; this has several advantages: There is

no blower wheel prone to wear (a factor with abrasive materi-

als) and there is a vacuum in the piping; as a result no dust can

escape into the environment. What's more, the suction convey-

or solution saves space at the thermoforming line since the

blower is not located inside the granulator but on the bagging

rack. This also reduces the noise level in production.

Getecha offers various options for the BigBag accommodation.

There are height-adjustable racks for the suspension of one or

two BigBags. The racks for two BigBags feature a manual or au-

tomatic pneumatic switch as well as filling level control with

alarm signal. The pneumatic switch switches to the second bag

as soon as the first one is full. Before changing material the

pipe system is extracted clean to avoid different materials from

being mixed. The extracted air is cleaned through suspended

filter hoses or cartridge filters. The latter have a greater

cleaning efficiency and feature automatic cleaning.

The equipment of the Getecha package solutions covers the

complete process from granulation and extraction via transport

and bagging. Wherever folding blisters, inserts for praline

boxes or lids for cereal cups are produced in thermoforming,

the German company ensures a seamless and economic mate-

rial circulation.

Chinaplas 2016: Booth W4 K25

Getecha GmbH

Am Gemeindegraben 13, 63741 Aschaffenburg, Germany

www.getecha.deImage 4: Height-adjustable racks for the suspension of one or

two BigBags are available from Getecha for BigBag filling.

The racks for two BigBags feature a manual or automatic

pneumatic switch

56

2016中国国际橡塑展

Extrusion Asia Edition 1/2016

格诺斯工业废弃物回收技术

Chinaplas 2016: Industrial Waste Recycling Technology

格诺斯提供废丝和废膜直接回收交钥匙技术

在今年展会上格诺斯会展出MRS 挤出系

统的模型,1个RSFgenius过滤系统并展示其

工业废弃物回收技术。

在半成品产品比如废丝和废膜,重新回收使用引入整个

生产链中。回收物的使用减少了原料的需求从而节省了生产

成本。通过和世界级的专家合作,格诺斯公司提供包括尺寸

减少,喂料和挤出在内的全套设备和解决方案。取决于回收

原料的质量,撕碎机或磨碎机可以被用来确保外来物料的可

加入性。这些轻质物料会通过喂料装置(喂料螺杆)被直接

加入到MRS 挤出机或更进一步的处理(在喂料前进行压缩)

Gneuss offers turnkey solutions for direct reuse of

fiber and film waste:

At this year’s Chinaplas Gneuss will exhibit a model of its

MRS Extrusion System, a RSFgenius Rotary Filtration System

and present its Industrial Waste Recycling Technology

.

I

n the manufacture of semi-finished products such as fibers or

films, waste that can be recycled and reused as a raw material

is repeatedly produced along the entire production chain. Re-

claiming waste reduces the need for raw material and thereby

saves on production costs. In cooperation with worldwide spe-

cialists, Gneuss offers complete system solutions including size

reduction, feeding and extrusion. Depending on the quality of

图4:Getecha可提供大袋装袋站,支架的高度可调节,可悬吊一

个或两个大袋,气动开关可手动或自动。