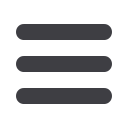

UC 36 G2 promises high efficiency

The UC 36 G2 Corrugator lives up to the G2 name. It can

achieve production speeds of up to 60 m/min without breaking

a sweat. The UC 36 with 80 pairs of mold blocks can reach pro-

duction outputs for PVC corrugated pipes (cable conduit) of up

to 250kg/h.

Achieving new levels of quality and convenience

UNICOR completely redesigned the mold blocks to further opti-

mize the quality of the pipes. Now all four external sides of the

mold blocks are uniformly cooled, providing a very uniform

heat distribution in the mold blocks. Adjustments have also be-

come a thing of the past thanks to a mechanical allocation so-

lution for the mold blocks. Time-consuming adjustments are

therefore completely eliminated.

Components made in Germany

To guarantee a long lifespan for the corrugators with minimal

maintenance, UNICOR uses products from German suppliers.

Servo motor, gearing, touch display and much more carry the

“Made in Germany” seal of quality .

The basic version of the UNICOR UC 36 G2 is equipped with 50

pairs of mold blocks. This can be expanded to 65 or 80 pairs at

any time to increase production capacity. The optional vacuum

can also enhance the production of corrugated pipes for a wide

variety of applications. More information about the new G2

corrugators from UNICOR is available online at:

30

Pipe Extrusion

Extrusion 3/2016

UNICOR GmbH

Industriestr. 56, 97437 Hassfurt, Germany

http://qusac.unicor.com,

www.unicor.comUC 36 G2 (Image: Unicor)

Long-term profitability in the

production of corrugated pipes

with 4.8 to 36 mm diameters

G2 is the name of the

latest generation of

UNICOR corrugators for

manufacturing technical

pipes with diameters up

to 135 mm. The concept

provides pipe manu-

facturers around the

world with utmost quality at

unbeatable prices across the

entire life of the system.

UC 36 G2 Corrugator

Extrusion Line for Multilayer

Pipes Production

AMUT continues to improve the technolo-

gy of lines producing PP pipes with glass

fibres and mineral filler (calcium carbonate

or barium sulphate). The pipes extruded

with this technology are used for hot

water piping and soundproofing drainage

piping. The glass fibres improve the elastic

and mechanical properties of the material,

the reduction in pipe thickness, maintain-

ing the same resistance level, and the ther-

mal expansion (less joints are required).

The quality of pipes is definitely enhanced.