During the months of

June and

July 2016

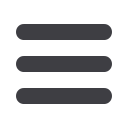

, WM Thermoforming

Machines will showcase two

complete IN-LINE production

plants INTEC FT 900/3 which will

produce two-color disposable

8 and 10 Oz cups made of multi-

layer polypropylene. Both

machines have been purchased

by one of the leading disposable

item manufacturers in the

Americas.

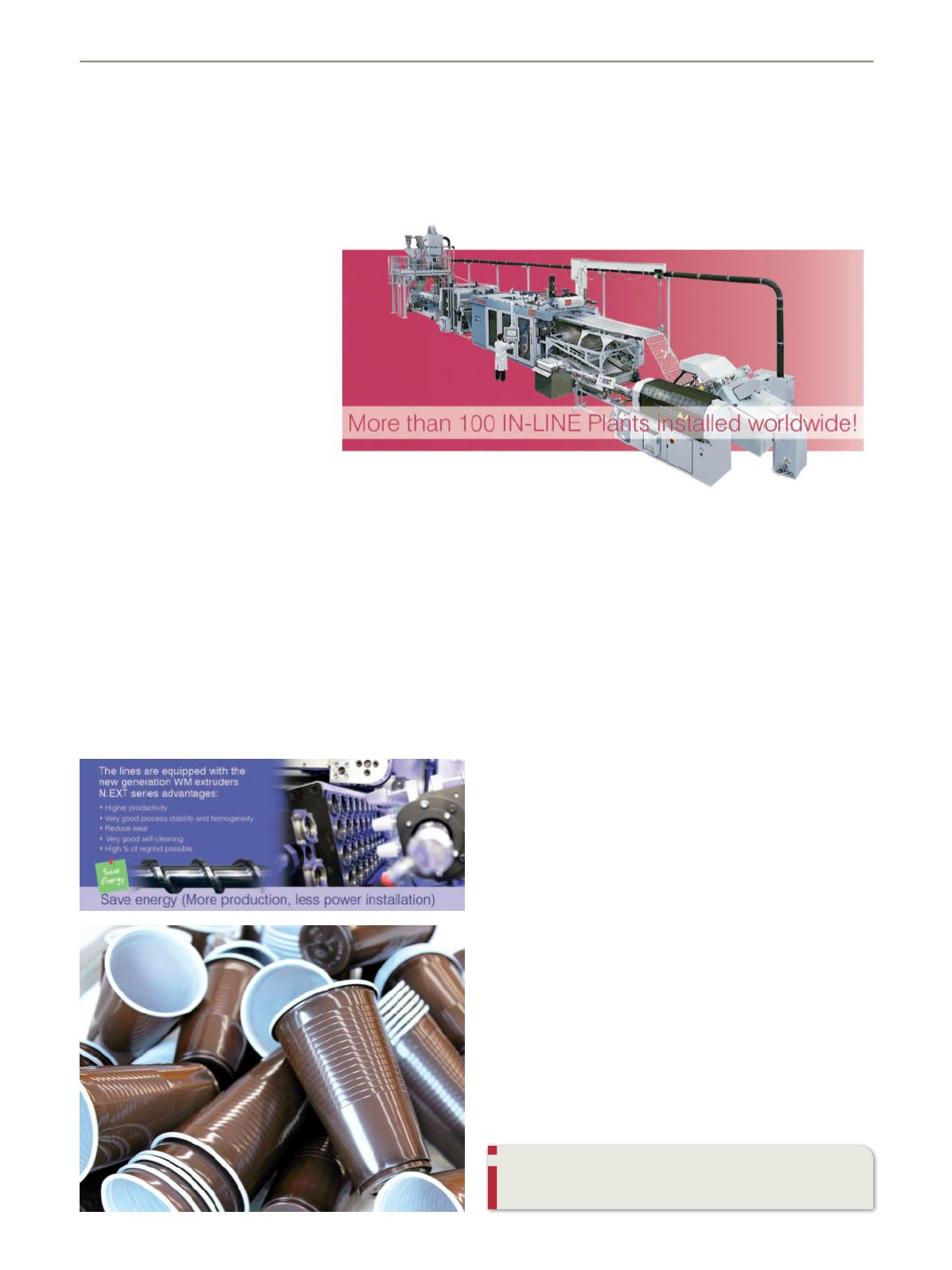

T

he INTEC FT 900/3 consists of an automatic dosing and

feeding unit for raw material in granules, including the ma-

nagement and recycling system for the scrap material. Both

lines are equipped with the latest generation of WM’s N.EXT

extruders, which thanks to the new screw design, guarantees

higher productivity, less power consumption and, at the same

time, increases process stability and homogeneity.

The WM extrusion line consists of a main extruder with a screw

diameter of 75mm where the regrinded material is mixed with

the Polypropylene based material and filled with 70 percent of

talc. The two co-extruders with a diameter of 45 mm are used

A Fully Automated System

will transform 900 Millions of Rimmed PP Cups a Year

36

Thermoforming

Extrusion 3/2016

WMWrapping Machinery SA

Via dei Pioppi 3, 6855 Stabio, Switzerland (CH)

www.wm-thermoforming.comfor the outer colored layer. The total extrusion capacity of the

group is 1’500 kg/h.

The flat die head of the extrusion unit feeds a vertical lamina-

ting calender with three rolls creating a sheet width of 930mm

and a thickness ranging from 0.2 to 2 mm. The extruded sheet

is then sent in line to the transporting system of the INTEC FT

900/3 thermoforming machine which use a tilting lower form-

ing platen and a servo-assisted plugging unit. The forming tool

will consist of a 54 cavity mold and can accommodate molds

with a maximum size of 880x520 mm which clamping force is

of 75,000 DaN. The tilting system of the movable lower platen

is developed based on an innovative double DESMODROMIC

system of cams and levers operated by a servomotor.

After simultaneous forming and in-mold trimming, the cups are

removed from the bottom half-mold through a tilting plate ro-

tating at 75 degrees which is driven by aspirated spindles. The

cups are then transported and unloaded automatically into va-

rious rows on the conveyor belt feeding consecutively the WM’s

in-house developed rimming unit consisting of three rotating

screws.

This unit folds the upper edge of the cups prior to sending the

piles to the counting, packing and boxing units.

The waste of the residual perforated polypropylene is ultimate-

ly sent in-line to a soundproofed grinding mill reducing the

scrap into flakes in order to be blown into a dosing/mixing unit

located above the extrusion unit. This creates a closed loop

from the raw material to the finished product with the direct in-

line recycling of wasted material.

The INTEC 900/3 can produce up to 120,000 pcs of 200 cc

cups per hour, minimizing energy consumption using only one

operator.