31

Extrusion 2/2017

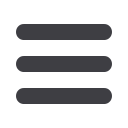

Debuts of the ACF Series driven by

EASY at CHINAPLAS

The ACF series assures a flexible produc-

tion for a wide range of articles, handl-

ing different materials, such as PET, APET,

RPET, CPET, OPS, HIPS, PS, EPS, PP, PLA,

PVC, has a modular concept and can be

supplied in different configurations. In-

line solutions are also available.

An exceptional repeatability and high-

speed performances make these ma-

chines absolutely unique and competi-

tive. The forming and cutting presses are

purposely equipped with counterba-

lanced platens.

(Images: AMUT)

T

he extremely positive feedback re-

ceived after the show has determined

AMUT COMI to embrace also the South

East Asian market, presenting the ACF

820 model in operation during China-

plas exhibition. This model is configured

in three stations (forming - cutting - sta-

cking), with formig mould size of 820 x

650 mm and clamping force of 240 kN.

The cutting station has area of 800 x

630 mm and clamping force of 600 kN.

The heating oven is a new development

with 5-step length or 3.250 mm, and

permits to process thick PP sheets with-

out any need of pre-heater.

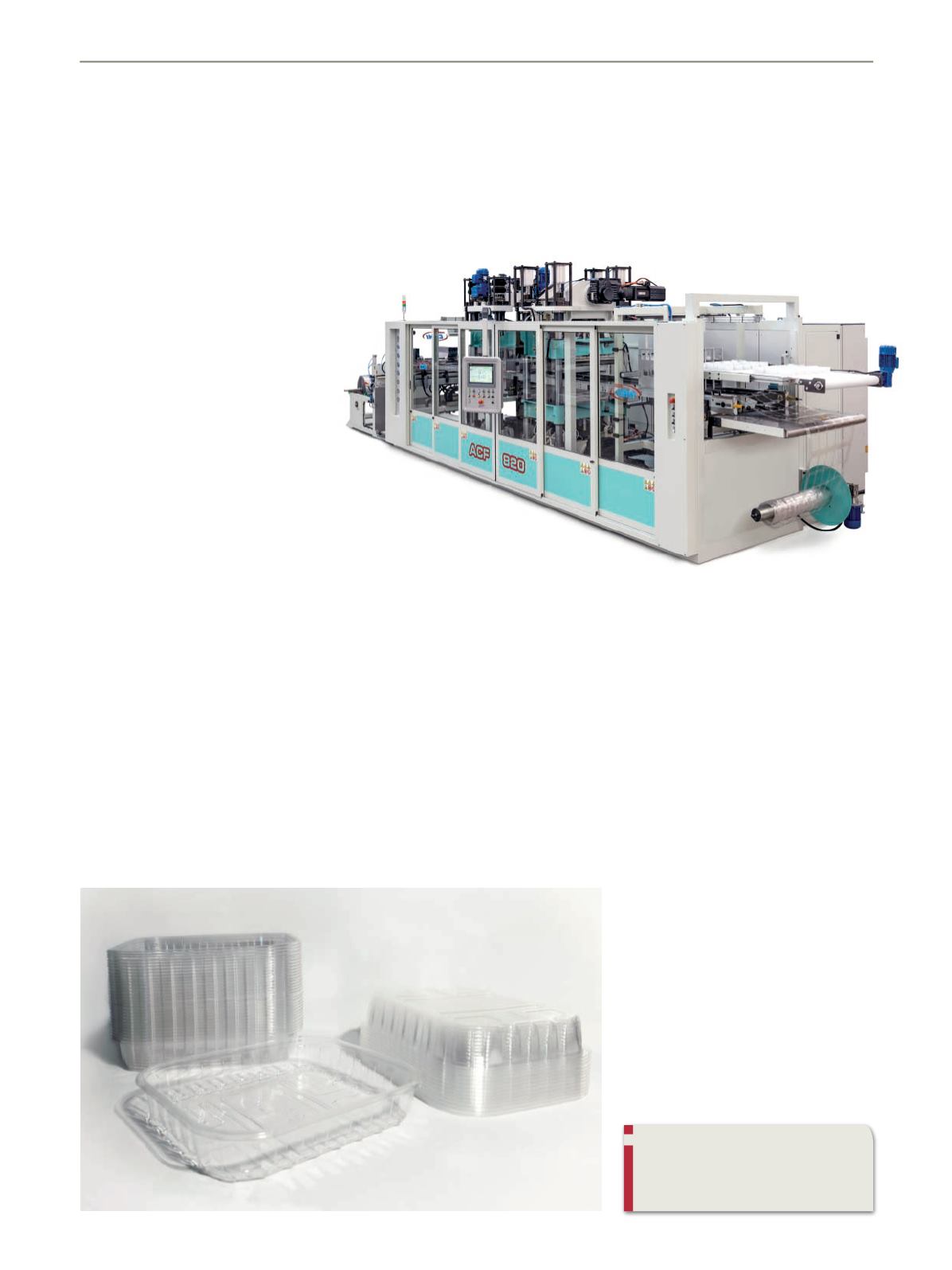

The visitors will see the machine deliver

PET punnets starting from 350-µ foil and

reach a production speed up to 60 wet

cycles per min in the configuration with

15-cavity mould.

AMUT GROUP

Via Cameri, 16 - 28100 Novara - Italy

www.amutgroup.comChinaplas 2017: Hall 4, Booth C45

The ACF is the latest series

of thermoforming

machines developed by

AMUT COMI with premiere

demonstration during the

K Show in Germany.

All AMUT COMI thermoforming ma-

chines are driven by EASY, the smart

HDMI that understands the data set by

the operator and processes them pro-

posing optimized solutions. AMUT COMI

is keeping up with advances in technolo-

gy, complying with the smart manufac-

turing and Industry 4.0 trends.

Main performances of EASY:

• Automatic adjustment of the parame-

ters of the cycle based on the set speed.

• Optimized diagnostic with information

for research and fully independent solu-

tion of the problems.

• Monitor displaying of I/O PLC cards.

• Automatic check of the set parameters

refusing data that are not compatible

with the predefined cycle.

• Detailed pie chart of all functions of

the automatic loop.

• Energy saving system with optimiza-

tion of oven heating in relation to mould

size.

Thermoforming