47

Extrusion 2/2016

Teknor Apex

wire 2016: Hall 09 / E06-1

ZUMBACH Electronic AG

www.zumbach.com3-axis ODAC 550 system,

measuring an Offshore cable of

500 mm OD

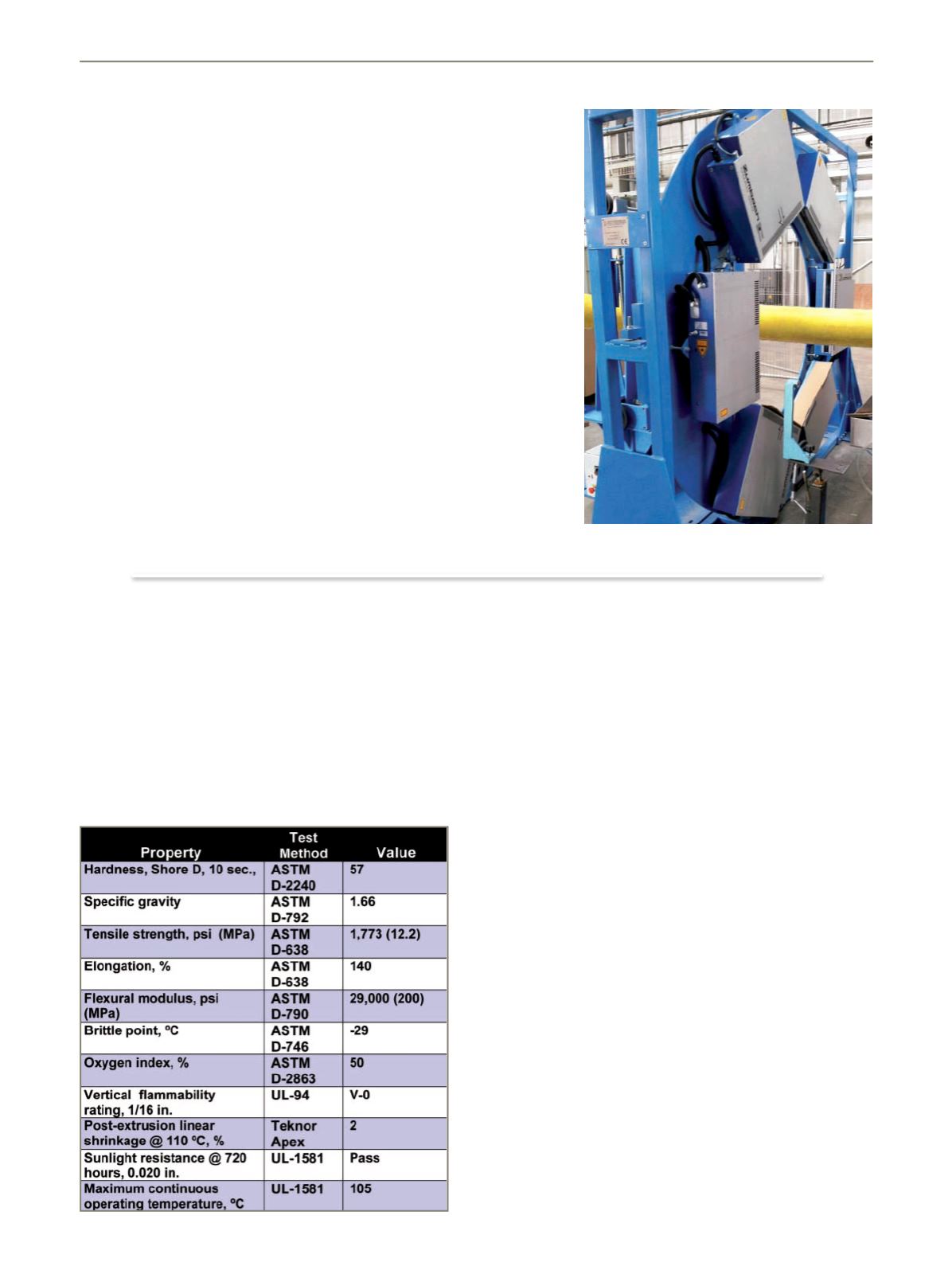

Typical Properties of

Halguard

®

58625

Compound

(Source: Teknor Apex

Company)

Complete line of measurement and

control equipment for any on-line

and manufacturing process:

• New 1, 2 and 3 axis diameter gauges

of the high precision, well known

ODAC

®

series for any wire and cable.

New models with special beam geome-

try, fault detection function and high

scan rate.

• The advanced ODEX

®

concentricity and

diameter gauge for wire extrusion. Fully

non-contact, based on magnetic and la-

ser technology.

• New LSV length & speed gauges for

down to zero speed measurement.

• New and state-of-the-Art Spark Tester

AC and DST systems.

• Advanced KW fault detectors with new

local BAE control and display unit.

• New economic, modular high perfor-

mance USYS IPC data acquisition, pro-

cessing and display units.

• RAYEX

®

D series: ZUMBACH’s

X-Ray measuring & control system

for CV lines, for wall thickness

(3 layers), eccentricity and diame-

ter/ovality for CV lines.

• PROFILEMASTER

®

series: High-

end Non-contact Profile and Shape

Measurement, Combining Laser

and CCD Technology for shaped

wire and any other profile.

Teknor Apex

www.teknorapex.comCompounds for Fiber Optic Cable:

A new halogen-free flame retardant

(HFFR) compound for fiber optic cable

provides excellent flame retardance

while exhibiting significantly lower post-

extrusion shrinkage than similar com-

pounds with comparable flame proper-

ties, it was announced by Teknor Apex

Company, which will feature the new

product at

Wire 2016

along with a pre-

viously introduced low-shrinkage grade.

Halguard

®

58625 compound has a UL-

94 flammability rating of V-0 and an oxy-

gen index of 50%, while exhibiting post-

extrusion linear shrinkage of only 2%.

The new product is an addition to the

Halguard family of

compounds providing

an economical alter-

native to premium

grades because of

their innovative flame

retardant formulation.

Low shrinkage is espe-

cially desirable in fiber

optic applications be-

cause it reduces the

degree of stress impo-

sed on the sensitive

optical fibers during

post-extrusion temperature cycling and

over time during end use. A low-shrinka-

ge grade introduced in 2015, Halguard

58620, exhibits a Shore D hardness of 54

and shrinkage of 1.3%, with a UL-94

flammability rating of V-1 and oxygen

index of 40.0%.

Teknor Apex recommends Halguard

58625 compound for cable used in mass

transit, data centers, cell towers, and

other infrastructure applications. For

outdoor uses, the new product exhibits

good sunlight resistance when tested per

UL-1581.

“Halguard 58625 compound costs less

than comparable premium materials

while exhibiting little compromise in per-

formance properties,” said David Braun,

wire and cable industry manager for the

Vinyl Division. “It is the newest member

of a series of HFFR compounds deve-

loped by Teknor Apex to meet a range of

customer needs while providing lower-

cost alternatives to other Halguard and

competing HFFR products in general-pur-

pose applications.”

The new compound is available world-

wide.