Technologische

Highlights

Vom

4. bis 8. April 2016

präsentieren die beiden

Weltleitmessen wire, Internationale Fachmesse

Draht und Kabel, und Tube, Internationale Rohr-

fachmesse, bereits zum 15. Mal gemeinsam techno-

logische Highlights aus ihren Branchen auf dem

Düsseldorfer

Messegelände.

Die wire zeigt auf einer Fläche von rund 58.600 m

2

netto Maschinen zur Drahtherstellung und Verede-

lung, Werkzeuge und Hilfsmaterialien zur Verfah-

renstechnik sowie Werkstoffe, Spezialdrähte und

Kabel.

www.wire.de www.tube.de46

Zumbach

wire 2016: Hall 11 / D41

Tube 2016: Hall 05 / E17

Preview

Extrusion 2/2016

technique and linear sensor technology

are used.

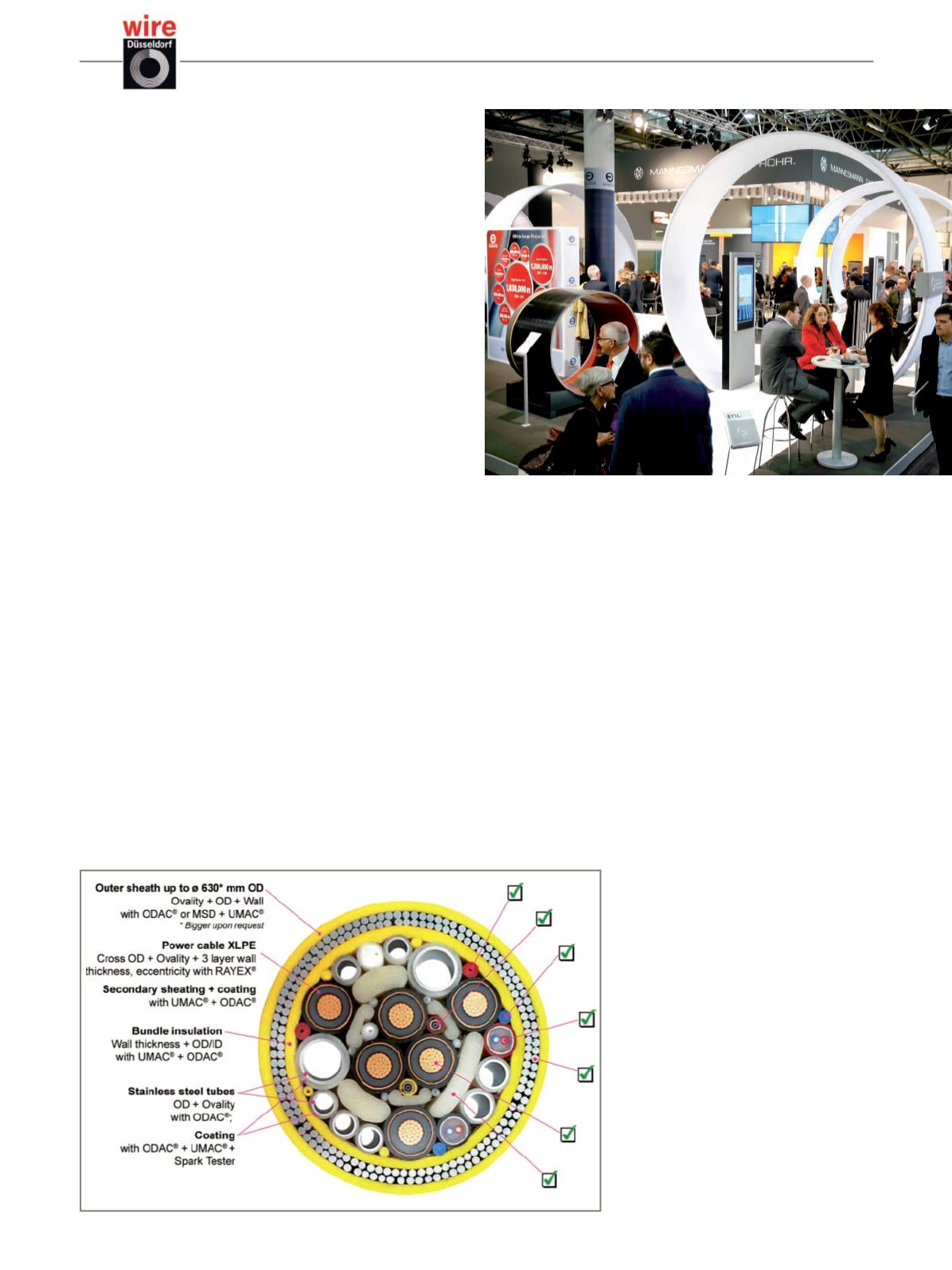

The production of offshore Flexibles in-

volves complex process’s requiring vary-

ing individual performances for quality

control. Any deviations from the required

standards can risk horrific consequences

if failure occurs depending the applica-

tion scenarios. In order that the risks for

future product failure are eliminated dur-

ing the manufacturing processes, such as

wire drawing, profile rolling / extruding,

stranding and sheathing, ZUMBACH pro-

vides reliable solutions for the measure-

ment of all critical parameters.

All Components in View:

Zumbach will showcase its extensive

portfolio of Dimensional Measurement

and Inspection Systems for Wire Draw-

ing, Wire Insulating and Cable Jacketing

processes as well as for Rod and Bar

Mills. In order to achieve the highest pre-

cision and best price-performance ratio,

different technologies such as laser

scanning, X-ray, ultrasound, light-section

Any Offshore flexible can be measured with gauges from ZUMBACH

Material savings thanks to measure-

ment and control of eccentricity and

wall thickness

:

The versatile high-tech ultrasonic system

WALLMASTER offers application-specific

solutions for measuring and monitoring

wall thickness. The measuring data pro-

cessor with touch-screen display gathers

data and QC fully automatically.

In combination with ultrasonic UMAC

®

scanners and various ODAC

®

diameter

measuring gauges as well as with error

detectors, the measuring and monitoring

scale can be expanded to outside and in-

side diameter, statistics, SPC and proces-

sor communication.

Using Zumbach’s WALLMASTER mea-

surement and control systems, manufac-

turers can economise their expenditure

of raw materials. The ROI is achieved

within a few months. The use of these

systems also allows reducing considera-

bly the start-up time.

New ultrasonic scanners for flexible

diameter adjustment

This novel construction (pat. pend.) is

going to be one of the exhibition's high-

lights: the traducers can be either indivi-

dually or simultaneously adjusted to the

best possible measuring position within

seconds. The scanners represent a smart

and simple solution for full non-contact,

in-line eccentricity and wall thickness

measurement of cable jackets, tubes

and hoses.