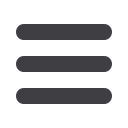

HGM 60/200 Swivel-type Screen Support

Herbold Meckesheim:

the five columns

of our plastics recycling

T

he machine and plant manufacturer from

Meckesheim/Germany will present their five columns for

an efficient and cost-effective recycling of plastic waste, cha-

racterised by low operating costs and a higher efficiency.

Pre-size-reduction

Pre-size-reduction is an important process step if the feeding

material is too bulky for the usual procedure or if the material

is in a first step only to be coarsely shredded for a subsequent

sorting, classification or inspection. For this purpose, shred-

ders, granulators, guillotines and hammer mills are used as

pre-size-reduction machines, e.g.

HOG Shredder HGM series

Designed for size-reducing difficult, especially viscous materi-

als or materials containing foreign bodies where the service

lives of standard granulators are too short and where traditio-

nal shredders do not yield the desired end product. Available

in wet execution for extremely abrasive materials, such as agri-

cultural film, WEEE, etc.

Size-reduction

Herbold size-reduction machines grind all types of plastic

waste, it does not really matter whether it comes from injec-

tion or blow moulding, thermoforming, rotomoulding, flat film

extrusion or blow moulding extrusion, calendaring or waste

from the production of pipes, profiles and plates or from the

manufacture of other plastic products, e.g.:

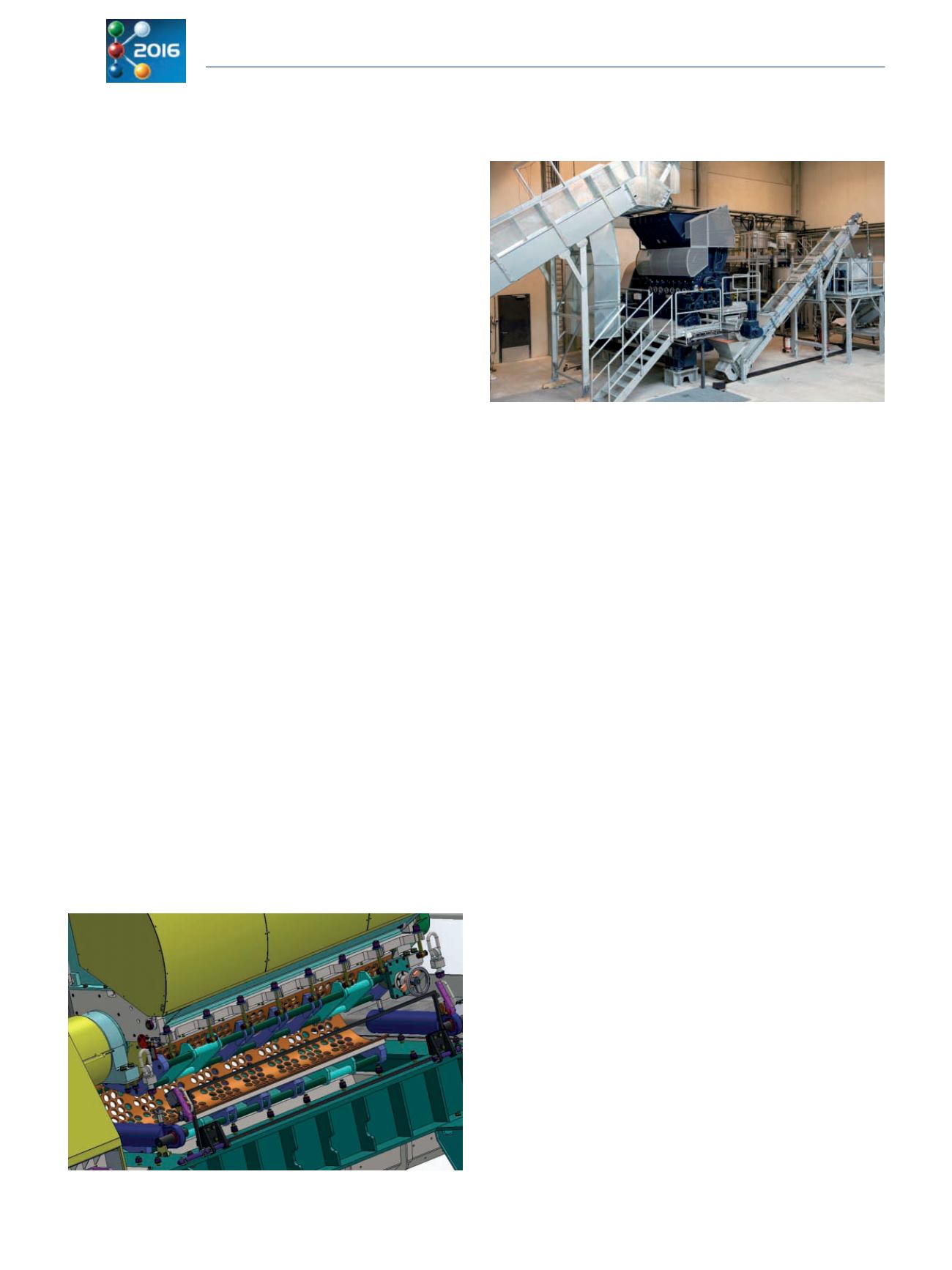

Granulator SB with forced feeding (patented)

The patented Herbold granulators with forced feeding of the

SB type have been successfully in operation worldwide for

Herbold Wet Shredder HGM 60/200

Extrusion International 5/2016

56

many years now. The material is not fed into the grinding

chamber by gravity as is the case with traditional granulators

but as a continuous and even flow by means of feeding

screws. In case of difficult applications, only few suppliers in

the market are able to find an appropriate solution.

The problem’s solution is the rotor design of the SMS Granu-

lator (Exhibit SMS 80/120 SB 2). The one-piece rotor guaran-

tees stability. Welding seams cannot break since they do not

exist. The knives of this rotor cannot shift because they are

crewed onto a massive back limit stop. This special design fa-

cilitates cleansing for there are no “dead angles” where rem-

nants of grinding material could depos

Fine Grinding

“Fine grinding“ in our application is pulverising below 1 mm.

For this purpose – depending on the product – we use granu-

lators or impact disc pulverisers, e.g.:

Impact Disc Pulveriser PU Series

Herbold impact disc pulverisers are high-speed fine grinders.

They are used with granular and brittle materials, e.g. PE gra-

nules or rigid PVC grinding materials.

Washing, Separating and Drying

End of life post-industrial and post-consumer plastic products

are used, mixed and contaminated plastics. Before they can

be used again, they have to be washed and/or separated. With

the successful commissioning of the film washing line at Ro-

depa Plastics B.V. Herbold Meckesheim proved that a high-

quality end product can be obtained by separating undesirable

plastics with the hydrocyclone separation step.

Mark Langenhof Managing Director from Rodepa Plastics B.V

underlines: “Rodepa has taken a big step forward in recycling

contaminated waste that is to newly integrate the production

of film. This has only been possible with the best plant engi-

neering. With Herbold Meckesheim we have now found the

ideal partner in order to cooperate successfully.”