In the marketing the psychology

of the colour throw its weight

around, since from our birth our

minds are programmed to

answer to the input colours give

us. A demographic research on

colour demonstrates how impor-

tant our visive perceptions are,

the colour is the fundamental of

visual code, it helps us to under-

stand reality, transmit moods,

interact with our nervous system,

influences our perceptions, our

judgment and our sensations.

Each colour can communicate a

precise feeling and have a

psychological effect.

For example in a supermarket the

colour connected to each sector is

studied in every detail and the customers declared that the colour is the main element that bring to the

choice of one product instead of another.

Following the Trend of the

American Red Cup

R

ed is the colour of the fire, is the co-

lour of passion, can symbolize

warmth and with his different shades

can mean the power of attraction, but

also danger, it’s even the colour of the

devil. Can mean courage and innovati-

on. It’s the first colour of the rainbow,

the first colour the infant identify and

the first colour every people have na-

med.

And red is the colour chosen for the ico-

nic American PP cup. The classic big size

disposable beverage holder anyone can

remember in any US movie or TV series,

half-filled with any sort of drink or

crushed and thrown away.

This that might seem only a simple ob-

ject with a very few economical value, is

a real piece of technology and enginee-

ring. It has been studied in every aspect,

the perfect shape, so that can be stacked

without clung together but a shape that,

at the same time, can be easily removed

from the mould during the production.

The curved lip to avoid one cup from

sinking too tightly to the next, the bot-

tom more rigid to allow more air flow

between the stacked cups, the rigidity of

the cup itself so that the cup doesn’t

bend when filled, but also doesn’t have

too much grip.

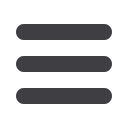

WM Thermoforming Machines in the

last year has followed the American

trend of the big size red PP cup. A total

of four In-line plants have been deliver-

ed, two of them for the American mar-

ket where this type of production is “tra-

ditional”, the other two in Europe, whe-

re the big red cup is a new tendency.

The In-line plants are the model INTEC FT

34

Thermoforming

Extrusion 5/2017

900/3, which start the process from the

automatic dosing and feeding of the PP

granules and finish its work with the re-

cycling of the scraps which are reduced

to flakes and re-sent to the dosing unit

at the end of the line.

The line is equipped with the new extru-

sion group manufactured completely by

WM Thermoforming Machines, the

N.EXT 75 which has a screw diameter of

75 mm and two co-extruders N.EXT 45

with a diameter of 45 mm. The total ex-

trusion capacity of the group is

1,096 kg/h.

The process continues with the flat die

head of the extrusion that feeds a verti-

cal laminating calender composed by

three rolls which produce the extruded

sheet having a width of 930 mm and a

thickness ranging from 0.2 to 2 mm.

The sheet is then transported in line

through a toothed chains system to the

thermoforming machine model FT 900,

where the products take shape. The FT