Extrusion International 3/2016

24

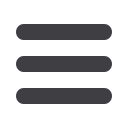

PVC-O pipes

and sustainability

B

earing in mind the problem of global warming affecting the

planet due to the greenhouse effect, many governments are

planning environmental policies seeking greener and environ-

mentally friendly solutions to apply in all areas and so maintain

a proper sustainable development of the available resources.

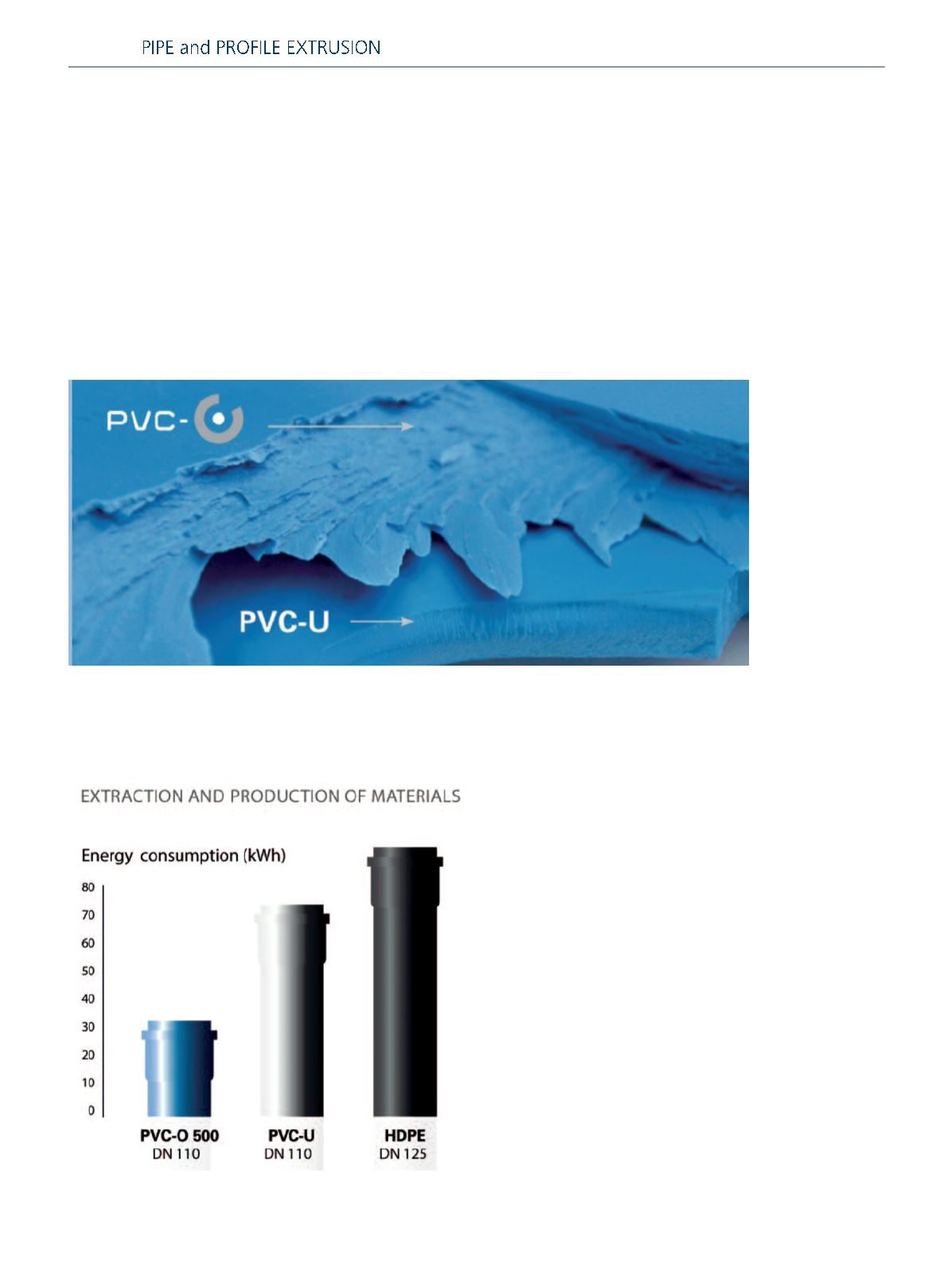

As a contribution to improve this problem, TOM PVC-O pipes

for the transport of water under pressure, become the most sus-

tainable option that exists in the market due to their lower en-

ergy consumption and lower CO 2 production associated since

they avoid unnecessary energy consumption throughout its long

useful life.

The factors that determine energy efficiency throughout the life-

cycle of a pipeline are mainly the type of raw material used, the

production process, the finished product and its useful life.

PVC-O lifecycle

During the lifecycle of the PVC-O pipes manufacture, we can

distinguish several phases:

1.Production phase

PVC-O pipes are manufactured by conventional extrusion and

subsequent molecular orientation. The extruded base pipe,

under certain conditions of pressure and temperature, is sub-

jected to a inside stretching of the pipe, the rearrangement of

the polymer molecules, forming a lamellar structure on the pipe