Extrusion International 2/2016

36

motan-colortronic shows the

latest developments in the

medical area during MEDTEC

motan-colortronic gmbh, Friedrichsdorf, Germany, a producer of systems for sustainable raw

materials handling in the areas of injection moulding, blow moulding, extrusion, compounding and

in the chemicals industry, will show the latest developments of the pharmaceutical and medical area

during MEDTEC EUROPE, Stuttgart, Germany, 12th to 14th April 2016.

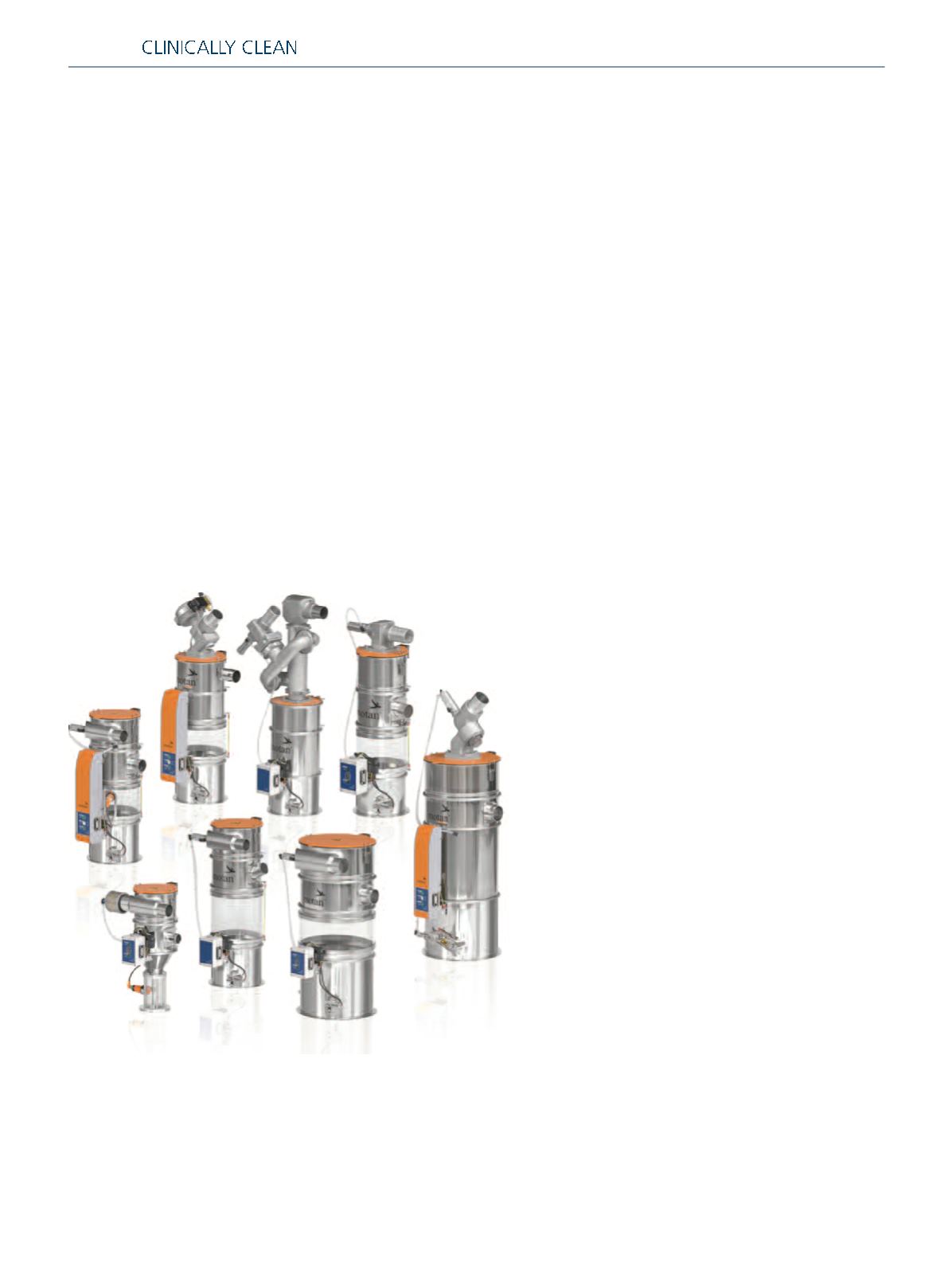

LUXOR CA S

Injection moulders producing very small parts are faced

with the unique challenge of being able to dry just the

right amount of material for their process. Operating in

extremely critical production conditions, these smaller

throughputs can present considerable problems. Con-

sequently, it is important to scale the drying to the size

of the moulding machine. The new LUXOR CA S range

of dryers fits perfectly into this concept. It is also suited

for cleanroom applications.

The LUXOR CA S range with hopper volumes of

0.75 / 1.5 / 3 and 5 litres has been conceived especially

for the production of small and micro parts. The range

is comprised of a modular line of correctly sized drying

equipment helping moulders to meet the small toler-

ances without waste or contamination. On account of

their light and compact construction, the dryers can be

simply mounted on all processing machines, also when

space is highly restricted. The LUXOR CA S compressed

air dryers take factory supplied compressed air which is

expanded to atmospheric pressure. This produces dry

process air – with a very low dew point – which is then

heated to the required drying temperature. No desic-

cant is necessary making the dryer prefect for clean

room conditions. All models are equipped with a ther-

mostat and low air flow safety switch to prevent over-

heating of the material in the event of insufficient air

throughput.

Due to the wide temperature range (30 - 180°C) the

LUXOR CA S micro dryers can be used for many differ-

ent materials. A pre-filter cleans the compressed air. This

METRO G loader range