Improves waterproofing

membranes performances

T

he recent market trend is gradually growing more in

favour of synthetic components than bituminous ones,

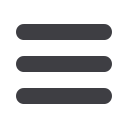

AMUT manufactures extrusion lines producing waterproof-

ing membranes capable to process different thermoplastic

materials, such as F/PVC, TPO, TPE. The use of these materi-

als definitely improves the technical performances and the

physical features of the membrane, complying with interna-

tional standards and requirements in the civil works sector.

AMUT technology allows to:

1-multi-layers membrane production in one-step

(no off-line lamination required) using a single calender prop-

erly designed. This process reduces the costs and simplifies

the running operations for the operator;

2- flexible production guaranteed in terms of different ma-

terials processing on the same line;

3-multi-layer reinforced membranes production in one-step

by means of reinforcing elements laminated among the lay-

ers to enhance the mechanical resistance of the finished

product;

4- support base (fleece-back) lamination, usually on the

lower side of the membrane.

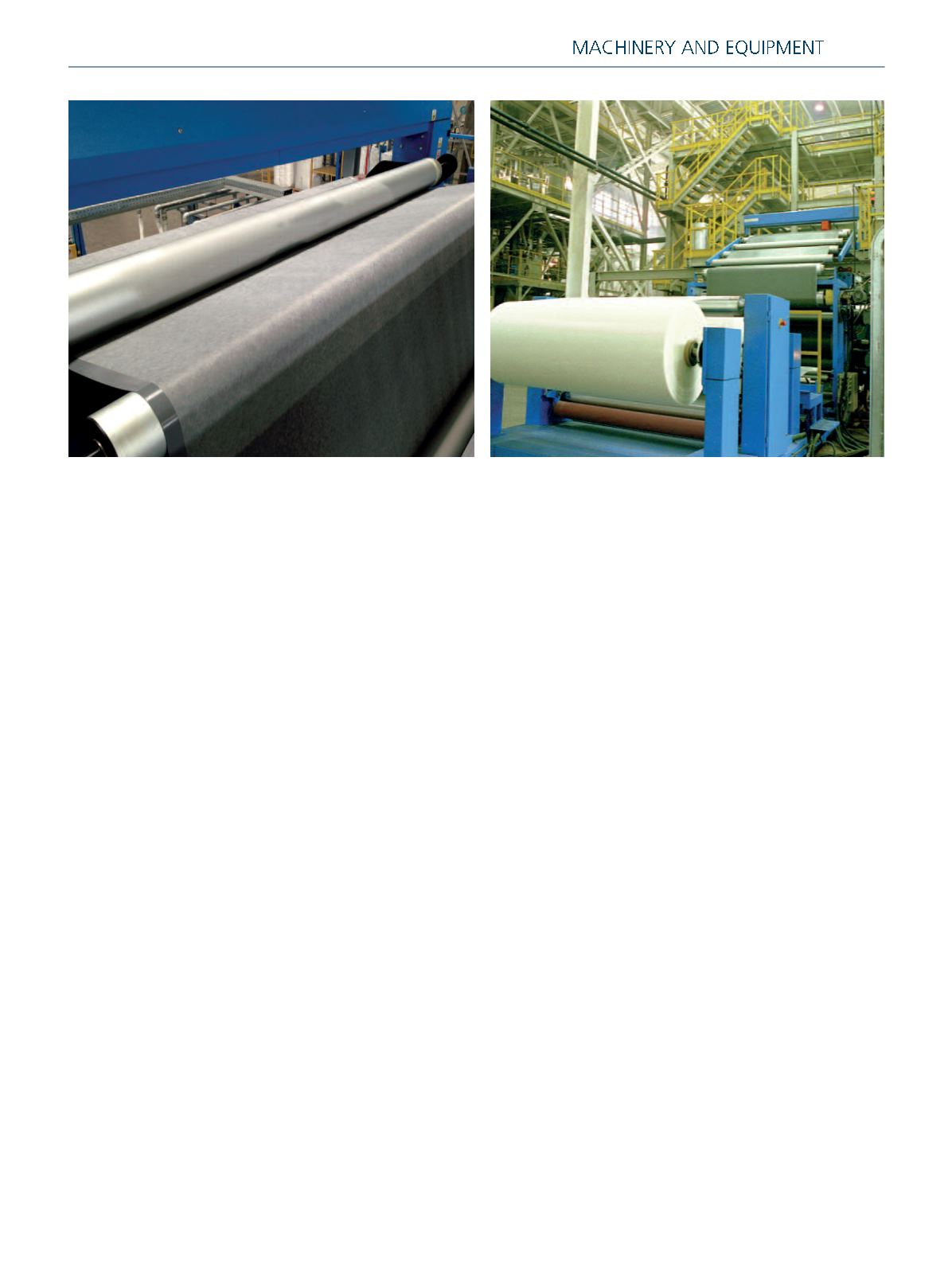

AMUT has recently supplied to a large Turkish customer, an

www.amut.itHYBRYD TYPE Line, capable to produce F/PVC

or TPO membrane 2.200 mm width, three layers of thermo-

plastic material and thickness range from 1 to

3 mm. The extruders’ screws special design is suitable for

both materials, so NO SCREW CHANGE is required. Within

the membrane’s configuration, it is included an inner rein-

forcing scrim and a bottom protective/supportive fleece

(fleece-back).

The total output is 1800 kg/h for F/PVC and 1250 kg/h for

TPO, giving an annual membrane production of more than 4

Million m².

A double-inlet calender consents to obtain a “sandwich”

geometry in a single step: the external layers, with insert-

ing/laminating of reinforcement in polyester or in glass fibre,

and coating of fleece-back.

The line is also equipped with thickness gauge measuring de-

vice, high accuracy winder unit to produce

jumbo and custom rolls and PC/PLC system to control all run-

ning operations of the line.

Extrusion International 1/2016

31