Extrusion International 1/2016

29

have captured a substantial market share in the past years in

the area of decking and their share in the segment currently

has two-digit growth rates.

The planetary roller extruder system features good mixing

prop-erties, short residence times and high surface renewal.

battenfeld-cincinnati is the only manufacturer that produces

all machine components in a

grinding process and thus

achieves precise geometries as

well as high-strength, wear-re-

sistant compo-nents.

battenfeld-cincinnati has been

offering planetary roller extrud-

ers for many decades, with

about 450 machines currently

working in the field in more

than 50 countries worldwide.

Beside the classic machines for

PVC sheet production, batten-

feld-cincinnati successfully in-

troduced the STARextruder for

direct extrusion of PET sheet to

the market a couple of years

ago. A planetary roller part for

degassing the PET melt is an in-

tegral component of this ex-

truder.

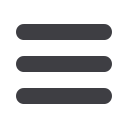

www.battenfeld-cincinnati.com www.noxprime.comLVTs can be used as flooring in different buildings, e.g. offices,

hotels, educational facilities or restaurants

(Photo: NOX Corporation)

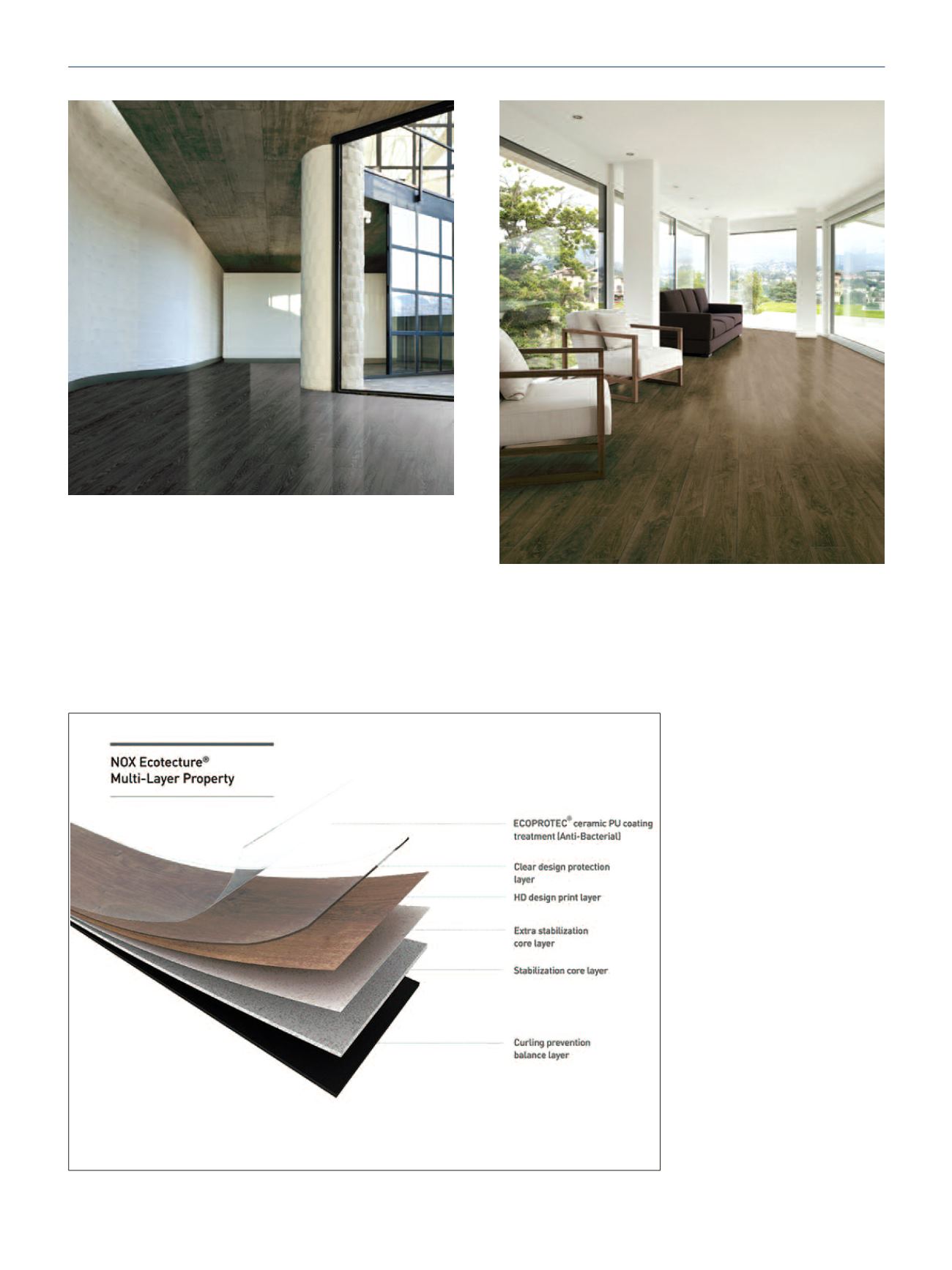

Configuration of an LVT: sheets with different properties are

laminated together to form a floor tile (Photo: NOX Corporation)