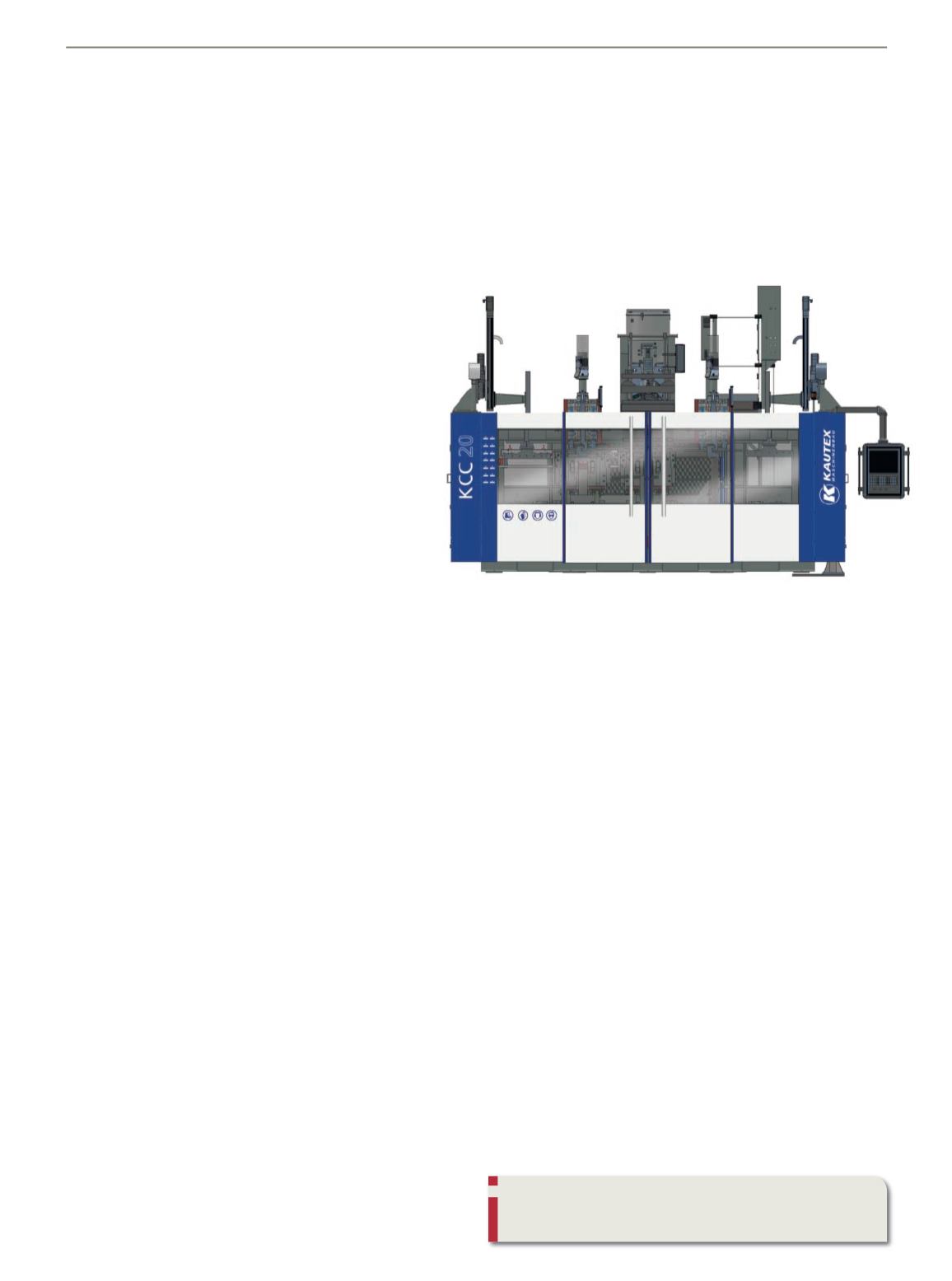

在今年的中国国际橡塑展上,考特斯公司(Kautex)

将展出新型号的中空成型机。从1997年开始,KCC系列

中空成型机就已经在中国的顺德投入生产,这次展出的

是成功的KCC系列中空成型机的第三代产品。这种新型

中空成型机是在去年十月的工厂开放日活动中推出的,

意味着KCC系列将全部重新换代。而且,这种设备整个

进行了重新的设计,具备了许多新的和改进过的技术特

性,从外观上看起来,这是新型的考特斯设备。

新一代KCC设备有着紧凑的外形,占用生产车间的

场地面积较小。具有更好的无障碍环境,不仅使中空成

型机易于维护,同时还使产品转换的时间更快捷。例如:

模具现在可以从侧面更换, 产品可以从设备的背面出

货。采用大量标准化的模块和部件,不仅减少了新机器

的投资成本,并且缩短了交货期。

Mark Lueddecke ,考特斯机械顺德副总裁,计划向市

场推出新一代的中空成型机,并逐渐地让整个范围的KCC产

品都由新一代产品所覆盖。他指出:“我们向所有种类的消费

品和工业产品的包装应用以及向汽车行业提供KCC设备。这

种高度的灵活性清晰地说明了为什么这种系列的设备能够在

几乎二十年的时间里持续地取得成功。”

在中国国际橡塑展期间,考特斯机械公司将同样会首次

展出新型KSB负压式中空成型机。 这一全新的型号特别设计

用于低闪点生产3D模塑部件。

全世界汽车工业领域对于塑料管道的需求始终在上升,

从那时到现在,由于使用了特殊的原料如尼龙6.6或PPS(聚

硫化苯),已经能够生产出更高耐热性的排气管道产品。

考特斯的BC5控制器采用现代化的操作理念,因此KSB

设备易于操作。此外,与以前的设备相比,新型负压中空成

型机占地面积大约减少了50% ,这样就节省了投资。

A

t this year’s Chinaplas Kautex Maschinenbau will present a

new model in its successful KCC series of extrusion blow

molding machines. This is the third generation of the KCC se-

ries, which has been produced in Shunde, China, since 1997.

The new blow molding machine model, which was announced

at the Open House event in October last year, represents a com-

plete relaunch of the KCC series. As well as a number of new

and revised technical features, the machine has also been com-

pletely re-designed, to visually blend in with the look of new

Kautex machines.

With its compact form, the new KCC generation takes up less

floor space in the production hall. Better accessibility not only

makes the blow molding machine easier to service, but also

speeds change over times. Molds can now also be changed

from the side, for example, and products are discharged from

第三代KCC系列中空成型机投产

Film Technology at Chinaplas 2016:

Third Generation of KCC Machines goes into

Production

34

2016年中国国际橡塑展上的薄膜技术

Extrusion Asia Edition 1/2016

the rear of the machine. A greater standardization of modules

and components has reduced the investment costs of the new

machine and shortened future delivery times.

Mark Lueddecke, Vice President of Kautex Maschinenbau in

Shunde, plans to introduce the new generation of machines to

the market on a gradual basis until the switch-over of the entire

KCC range has been completed. “We offer KCC machines for

all kinds of consumer and industrial packaging applications as

well as for the automotive sector. This high degree of flexibility

is precisely why this machine series has continued its success for

almost twenty years.”

Kautex Maschinenbau will also allow first insights in its new

KSB suction blow molding machine at Chinaplas. This brand

new machine type was specially designed for low-flash produc-

tion of 3D molded parts.

Global demand for plastic ducts for the automotive sector is ris-

ing all the time, ever since the use of special materials such as

PA6.6 or PPS has enabled the production of highly heat-resis-

tant exhaust ducts.

A modern operating concept with Kautex BC5 controller makes

the new KSB machines easy to operate. In addition, the new

suction blow molding machine takes up almost 50% less space

than previous equipment, thus reducing investment costs.

Chinaplas 2016: Stand E1 F41

2016中国国际橡塑展:展台号 E1 F41

Kautex Maschinenbau GmbH

Kautexstr. 54, 53229 Bonn, Germany

www.kautex-group.com