世界首台九流道挤出模头投入运行,能够生产多

层薄膜,将各层的厚度偏差减少三分之二

Film Extrusion:

World’s First 9-Manifold Extrusion Die is Up

and Running,Yielding Multi-Layer Film with

Two-Thirds Less Layer Thickness Variation

Nordson 最先进的多层复合模头可提供比同等水平

的共挤喂料块系统更严格的厚度公差,从而节约材料成

本,提高产品质量

Nordson Corporation 最新发布的共挤技术使得薄

膜加工商,尤其是那些使用高产量线专业生产特种产品

的加工商,能够在多层结构中保证各个子膜层严格的厚

度公差。

Nordson’s Most Advanced Multi-Manifold

Die Provides Tighter Tolerances than a

Comparable Feedblock System, Saving Mate-

rial Costs and Enhancing Product Quality

The latest advance in coextrusion technology from

Nordson Corporation enables film processors – par-

ticularly those with high-throughput lines dedica-

ted to a narrow range of products – to achieve

tighter thickness tolerances for the individual layers

in a multi-layer structure.

Nordson Extrusion Dies Industries 的九流道平模头在业

界首开先河,已成功完成试运行,可以使用不同的树脂生产

出九层薄膜。据 Nordson Extrusion Dies Industries 的首席技

术员 Sam G. Iuliano 介绍,尽管质量改善程度因具体的应用

领域而异,但一般来说,具有同等先进水平的喂料块系统生

产的薄膜往往存在 +/- 15% 的层间厚度差异,而 Nordson Ex-

trusion Dies Industries I 九流道模头技术能将各个子膜层厚度

公差普遍减少至 +/-5%。

Iuliano 先生指出:“高性能的包装薄膜通常采用昂贵的特

殊材料作为阻隔膜层。多层复合模头的精确度更高,使加工

商可以使用更少的昂贵材料制作成更薄的薄膜阻隔层。同时

又能提升产品质量,保证产品的一致性。”

流道是模头内部熔体流量的分配通道,专为特定的聚合

物而设计,具有复杂的内部几何结构,以形成均匀、顺畅的

流体,将材料分布其流道内的全宽。在多层复合模头中,每

层熔体流都有自己专门的流道,只有当每一层熔体流分别铺

展到全宽后,所有各层才会被汇聚到同一个单层结构中。相

比之下,共挤喂料块将多层熔体流合并成一个狭窄的多层“三

明治”结构,然后将整个“三明治”分配到一个单流道模头中,

20

薄膜挤出

Extrusion Asia Edition 1/2016

A

Nordson EDI nine-manifold flat die, the first of its kind, has

been successfully commissioned, producing nine-layer film

from various resins. While the degree of improvement will vary

with the application, in general Nordson EDI’s nine-manifold

die technology promises to reduce variation in individual layer

thickness from the +/- 15% tolerance often encountered with

comparably advanced feedblock systems to +/- 5%, according

to Sam G. Iuliano, chief technologist for Nordson EDI.

“This greater accuracy achievable with multi-manifold dies en-

ables processors to run thinner layers of the costly specialty ma-

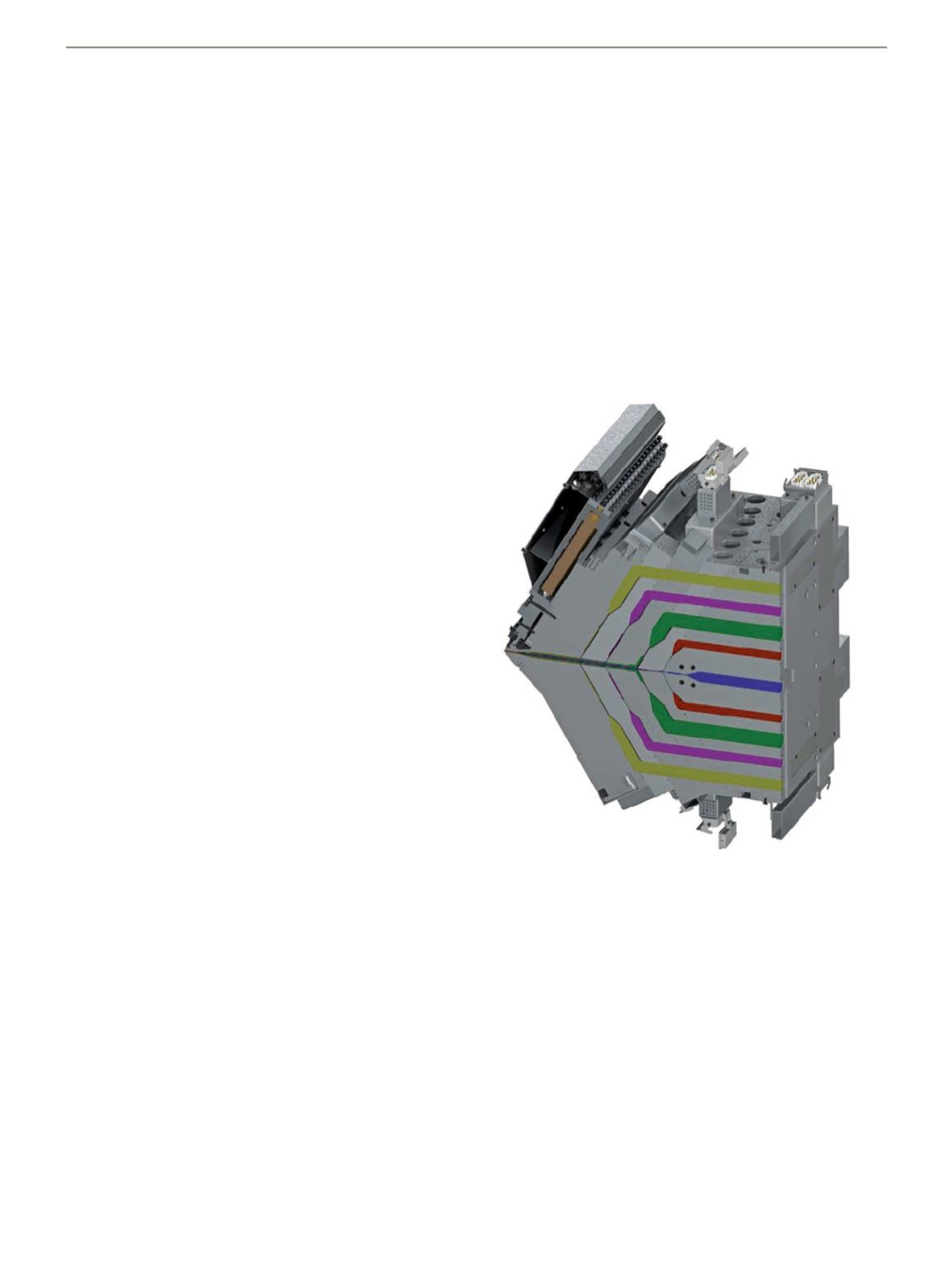

在 Nordson Extrusion Dies Industries 九流道模头的剖视

图中,各条聚合物流以不同的颜色表示。这些聚合物流组合起

来,形成一个多层结构,从左边的模头流出。位于左上方的是一

个 Autoflex 自动唇口调节装置。

Cutaway view of 9-manifold Nordson EDI die, with polymer

streams represented in different colors. The streams com-

bine to form a single multi-layer structure which exits the

die at left. Visible at upper left is an Autoflex automatic lip

adjusting unit