17

Extrusion Asia Edition 1/2016

➠

Davis-Standard, LLC

www.davis-standard.com➠

Advanced Plastic Extrusion, LLC (Apex)

www.apex-extrusion.com司位于康涅狄格州Pawcatuck的技术工

厂,戴维斯标准公司能够在片材生产线

上全方位地测试这两种树脂,并按照严

格的质量要求,采用这两种树脂原料成

功地生产出各种不同厚度的片材。对于

Buck而言,他的新公司在作出如此重大

的投资之前,已经准确地得到证明:这

就是所要求的设备。

n

High-End Sheet Operation

launched

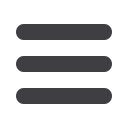

: A recently installed Davis-

Standard sheet system has Advanced

Plastic Extrusion, LLC (Apex), up and

running with excellent results. Apex,

based in North Carolina, is a new com-

pany focused on processing high-quality

sheet with a “class A” surface for spe-

cialty and laminated sheet applications.

Since starting production in September,

Apex has been processing sheet using

acrylic, ABS, HIPS, PC/ABS and TPO re-

sins in thicknesses ranging from .010 to

.187 inch and in widths up to 54 inches.

The Davis-Standard system, extruder

through roll stand, has been an integral

part of Apex’s successful launch from the

perspective of both technology and ser-

vice.

“After looking at several extrusion ven-

dors, we chose Davis-Standard because

of their quality, support services and

longevity in the business,” said APEX

founder and owner Ronnie Buck. “For

me to produce the very best sheet, we

had to go with the best equipment, even

if it cost more. Not only is Davis-Stan-

dard’s equipment proven, but they sur-

vived the economic downturn when ma-

ny others did not. The fact that they are

in it for the long haul and have the repu-

tation for quality is huge in terms of sup-

port and value after the purchase.”

The APEX team also appreciates Davis-

Standard’s R&D capabilities. Prior to pur-

chasing the system, Buck sent two of his

most critical resins to Davis-Standard’s

technical facility in Pawcatuck, Conn.

Davis-Standard was able to test the re-

sins on a full-scale sheet line, successfully

running both resins in various thicknes-

ses and to the exacting quality require-

ments. For Buck, this was confirmation

that his new company would have exact-

ly what it needed prior to making such a

large investment.

➠

AMUT GROUP

www.amut.it线,尤其是吹膜生产线可生

产多达九层的阻隔膜、技术

型薄膜、医用薄膜和复合薄

膜,流延膜生产线可生产拉

伸膜、尿片膜、PP薄膜、

呼吸膜和掩蔽膜;

• 单工位涂覆,双工位或

多工位涂覆生产线;

• 最多可达十色的无齿轮

柔版印刷机;

• 无溶剂或多系统复合机;

• 高速全自动分切复卷机。

n

Plastics Packaging Solutions

: Boo-

sting a reputation on custom-made and

turnkey projects, AMUT GROUP turns to

be an unmatched supplier offering the

most complete range of machinery for

the plastics extru-

sion, thermofor-

ming, recycling

and printing/con-

verting process.

AMUT

GROUP

and its companies

cover completely

the plastic lifetime

starting from its

recovery and then

passing through

extrusion, ther-

moforming

or

even flexo prin-

ting to be trans-

formed into the

n

得益于按照客户的需求定制和承接

交钥匙项目,AMUT集团的声望与日俱

增,成为了无与伦比的供应商,可为塑

料挤出、热成型、回收再生和印刷转换

加 工 提 供 范 围 最 为 完 整 的 机 械 设

备。AMUT集团及其公司的产品,覆盖

了完整的塑料使用循环周期,从原料的

再生开始,到挤出加工,再到热成型,

或许还有柔性印刷,直至成为最终产

品。从去年起,AMUT集团以AMUT

DOLCI BIELLONI的名称接手Dolci Ex-

trusion & Bielloni 公司,从此以后,集

团可以向其客户提供灵活多样的包装方

案:

• 生产多层薄膜的流延膜和吹膜生产

塑料包装的解决方案

final product. After taking over the Dolci

Extrusion & Bielloni company, operating

since last year as AMUT DOLCI BIELLONI,

AMUT GROUP is able to offer to its cus-

tomers also flexible packaging solutions:

• cast and blown lines for multilayer

films, in particular blown lines up to 9

layers for barrier, technical, medical and

lamination films, and cast lines for

stretch, diapers, PP, breathable and

masking films;

• single, tandem or multiple stations

coating lines;

• printing machines with up to 10 co-

lours gearless flexo presses;

• solventless or multisystems laminating

machines;

• high speed and fully automatic slitter

rewinders.