37

Extrusion International 4/2016

Approximately 25 years ago, Herbold

made the wet granulation technique

marketable and with it set standards

in the industry. The advantages of

wet granulation are obvious; less

wear and tear, no plastification due

to the optimum cooling during the

size reduction process, and a very ef-

fective separation from the first pro-

cessing step.

The Herbold Wet Shredder (fig. 1),

inside equipped with exchangeable

wear plates, shreds the infeed mate-

rial by the simultaneous addition of

wash water. The coarsest impurities

are already washed off during the

first process step.

Above all, this technique is well suit-

ed for highly contaminated mate-

rial such as agricultural film. It is also

suitable for post-consumer film from

households (fig. 2) and wet granula-

tion has significantly increased the

life between knife changes enabling

a more economic operation. Even

problematic material such as wood

and paper fractions inside the in-

put material can be handled better

through the wet shredding as water

allows for liberation from the mate-

rial early on in the process.

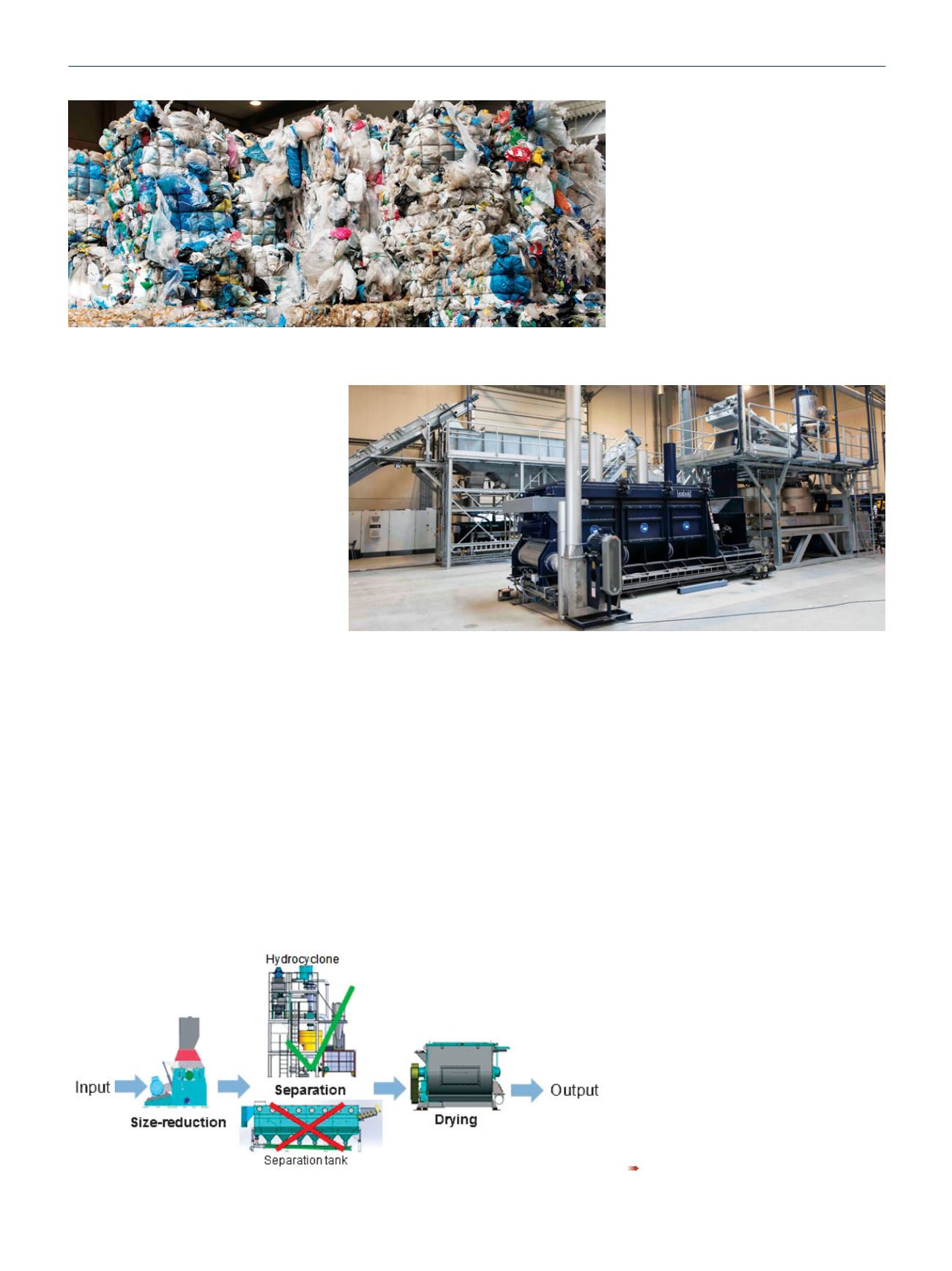

Further developments such as pre-

washing units, granulators with

forced feeding, hot wash steps with

ultrafiltration and hydro cyclone sep-

aration steps reduce energy costs,

process but also for the following

process steps in a washing line. The

washing line itself is no longer con-

taminated by extreme impurities,

hence the components have a longer

operating time and the final product

quality improves.

Retrofitting and upgrading of ex-

isting plants is an important topic –

HERBOLD MECKESHEIM assists with

expert technicians in order to incorpo-

rate the experiences of more than 300

installed wash and separation plants.

In the new technical center inMeckes-

heim near Heidelberg where current-

ly extensive enhancements are carried

out HERBOLDMECKESHEIMdevelops

solutions in collaboration with the

customer. A first trial with the cus-

tomer’s original material is free of

charge; the tests are processed with

machines in industrial scales.

Engineering, Manufacture, Delivery:

Pic. 2: Post-consumer film

Pic. 3: Hydro cyclone and Dryer, in the background Pre-washing unit

Pic. 4: Flowsheet Herbold Meckesheim

www.herbold.comfresh water and energy consumption

and increase at the same time the

quality of the final product.

The Herbold Pre-washing unit VWE

600/2 separates e. g. foreign bod-

ies such as stones, metals, glass and

sand using three different integrated

process steps. The feeding material

undergoes an intensive washing step

and then, in a third step, makes fur-

ther foreign material sink.

Both process steps reduce the wear

and maintenance costs not only for

the first step in comparison to a dry