➠

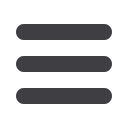

KraussMaffei Berstorff

www.kraussmaffeiberstorff.com www.kraussmaffeiberstorff.com/oeeplusThe KMD 63 K/R conical twin-screw extruder from the Performance series –

introduced to the market at the Chinaplas show for the first time

potential purchasers the option to pay a

visit to the company Weiyi that has its lo-

cation in Guangzhou and has several

CONVERTEX plants in operation.

"The need for new innovative quality

forms for special fields of application is

increasing and with their developments,

Windmöller & Hölscher takes these into

account", said Michael Fischer, CEO

W&H Asia Pacific. This applies for, e.g.,

the production of breathable diaper film.

With the 3-layer system VAREX II with In-

line-MDO stretching unit, W&H offers a

machine configuration for the producti-

n

At this years CHINAPLAS Windmöller

& Hölscher presented innovations in the

field of film production as well as innova-

tive sack concepts such as e.g. the film

sack AD proFilm MP, that is characterized

by a particularly high moisture protecti-

on. The blown film extrusion line

OPTIMEX for the production of film for

further processing on the AD PLASTIC 2

for the newly developed AD proFilm MP-

Sack mentioned above was also in the

focus. W&H demonstrated also compe-

tence in the field of manufacturing and

processing plastic fabric. W&H offered

Innovations at the CHINAPLAS 2017

on of a particularly thin breathable dia-

per back sheet film of only 12 g/m² – a

product that is predominantly produced

in cast film extrusion and with a higher

basis weight. Andreas Hoppe, customer

service consultant for extrusion systems

is convinced that "There is a clear trend

toward blown film. Blown films will re-

VAREX II –

Outstanding film

quality with

maximum

productivity

OPTIMEX –

Production of

first-class films

with attractive

investment costs

56

CHINAPLAS 2017 –

Review

Extrusion 5/2017

from a process technology standpoint.

The C6 control system with its many mo-

nitoring and control functions is the key

to an optimal production process.

"We consistently pursue high quality

standards in terms of a comprehensive

cost-effective production approach for

the Chinese market," Fan stresses. "In

our Performance series we rely on high

machine quality and German expertise,

but the product is specifically tailored to

Chinese needs. We source the perfor-

mance-determining components of the

machine from our main plant in Germa-

ny, while the finalization, installation and

commissioning takes place in Haiyan.

This allows us to offer our customers the

highest quality for the usual Chinese for-

mulations and market requirements,"

says Fan.

The molybdenum-welded screws and

the deep-nitrided cylinder provides a

high and effective wear-resistance in the

cost-effective processing of a wide varie-

ty of PVC pipe mixtures and thus ensures

a long machine service life.