Today’s modern PET recy-

cling facilities create high

quality flake from post-

consumer bottles. The

process starts with auto-

mated sorting equipment

which is used to remove

unwanted products from

the incoming material

stream.

A

fter the bottles have been pre-sorted and the labels have

been removed, they are visually inspected and sorted by

polymer type and colour. Once separated into clear and co-

loured streams, the bottles are ground and washed. During this

process, PET fines are generated and removed along with other

residues such as paper, aluminium, or PVC. The purity require-

ments of the final product vary depending on the end user. The

table

represents the purity levels typically required for flake

used to produce thermoform sheet.

The final quality of the PET flake is dependent on the composi-

tion of the incoming bales as well as the sorting technology

used in the recycling facility. This represents a daunting chal-

lenge for the melt filtration system in re-pelletizing, thermo-

forming and packaging tape lines, especially if the aluminium

fraction exceeds the specified 10 ppm dramatically.

The challenge is all the more intriguing when it comes to appli-

cations for the fines that are obtained when the PET bottles are

ground. These fines contain a much higher percentage of con-

taminants because more paper, aluminium, and PCV are separa-

ted during the screening and hot washing processes. Exactly this

48

Recycling

Extrusion 5/2016

makes them so difficult to utilize as a valuable raw material.

Due to the small size of the PET particles, they have a larger sur-

face area and hence absorb more moisture. Even with efficient

degassing technology during the extrusion process, the IV va-

lues tend to drop significantly. Additionally, higher contamina-

tion levels block static screens quickly, making it a challenge to

process this material, even with sophisticated back-flushing

screen changers. As a result, a large majority of the PET fines

are sold off at a very low price.

When considering that even a small recycling facility can produ-

ce more than 20 tons of fines per month, finding a solution to

filter this product could have a huge commercial impact on the

bottom line. With a proper pre-screening system in place com-

bined with a dryer, extruder and continuous melt filter, custo-

mers can now create a useable product from these fines.

High performance and a long service life

The ECO continuous melt filter manufactured by Ettlinger plays

a major role in processing highly contaminated feed streams.

The central component of the ECO melt filter is a rotating, cy-

lindrical filter screen with millions of conical holes that can be

supplied with a wide variety of screen sizes. When melt flows

through the filter, contaminants are retained on the outside of

the screen – in addition to solid contaminants such as alumini-

um and black specks as well. High-molecular and cross-linked

fractions which arise due to high temperature stresses are effi-

ciently separated from the melt stream along with gels. The

cleaned melt on the inside of the drum is supplied to the

downstream die via a system of flow channels.

The contaminants are wiped clean from the filter surface after

each rotation of the screen. They are then discharged from the

unit by means of a discharge shaft. If contamination levels

spike causing the pressure to rise, the drum automatically in-

creases. This ensures a steady pressure at all times. Unlike many

backflush systems, the purge from the ECO up to contains a

high percentage of contamination.

PET Fines from Recycled Bottles

A Valuable Raw Material

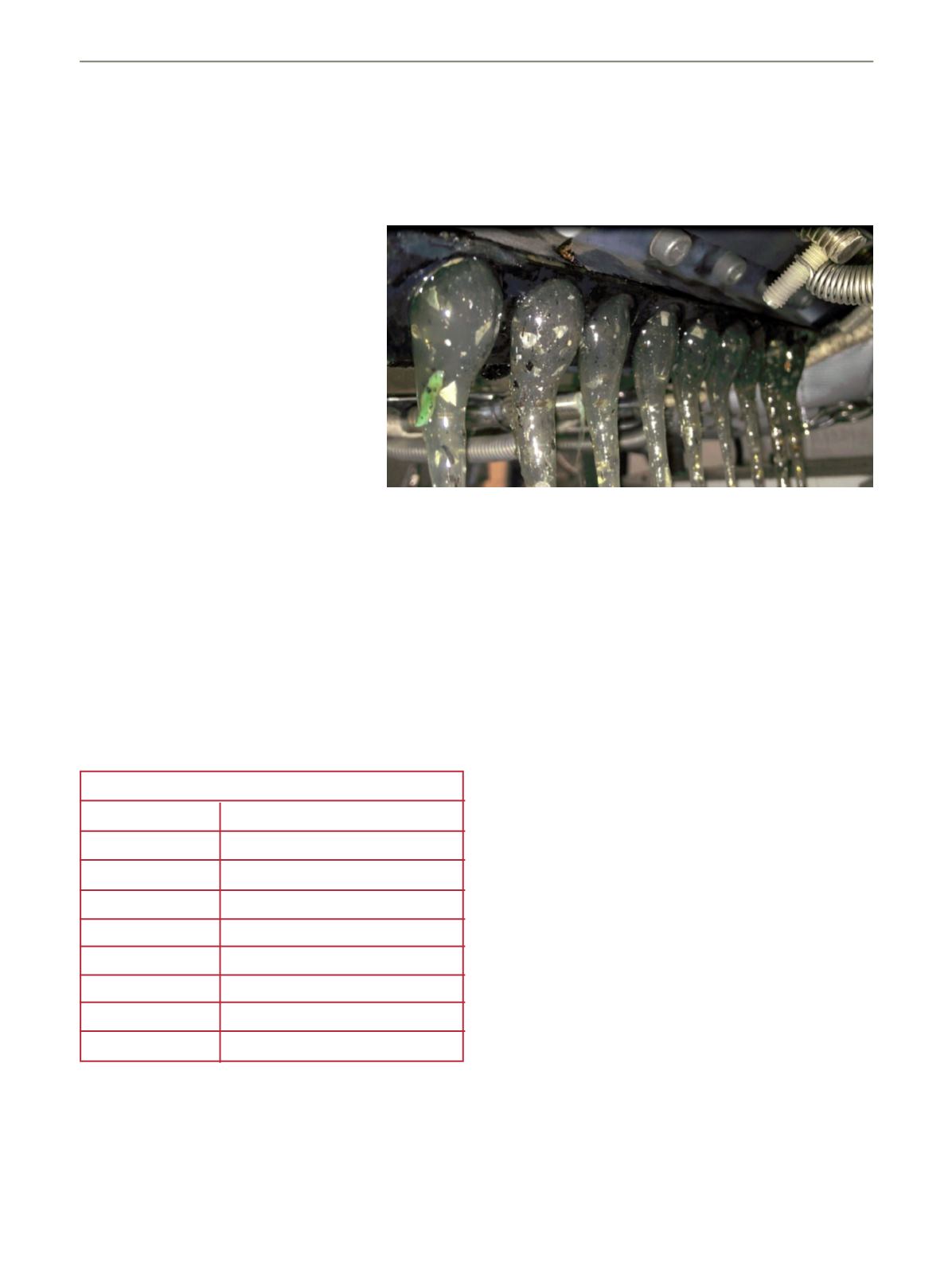

Clear PET, thermoforming sheet

Metal:

< 10 ppm

Paper:

< 50 ppm

Polyolefins:

< 50 ppm

Others:

< 25 ppm

Coloured flakes:

< 500 ppm

Light blue

< 50,000 ppm (5%)

PVC:

< 10 ppm

Adhesives:

< 400 ppm

Additives:

< 1200 ppm