A recently installed Davis-Standard

sheet system has Advanced Plastic Extru-

sion (Apex), up and running with excel-

lent results. Apex, based in North Caroli-

na, is a new company focused on pro-

cessing high-quality sheet with a “class

A” surface for specialty and laminated

sheet applications. Since starting produc-

tion in September, Apex has been

processing sheet using acrylic,

ABS, HIPS, PC/ABS and TPO resins

in thicknesses ranging from .010

to .187 inches and in widths up to

54 inches. The Davis-Standard sys-

tem, extruder through roll stand,

has been an integral part of Apex’s

successful launch from the per-

spective of both technology and

service.

“After looking at several extrusion

vendors, we chose Davis-Standard

because of their quality, support

services and longevity in the busi-

ness,” said APEX founder and

owner Ronnie Buck. “For me to

produce the very best sheet, we

had to go with the best equip-

ment, even if it cost more. Not on-

ly is Davis-Standard’s equipment

proven, but they survived the eco-

nomic downturn when many ot-

hers did not. The fact that they are

in it for the long haul and have the

reputation for quality is huge in

terms of support and value after

the purchase.”

The APEX team also appreciates

Davis-Standard’s R&D capabilities.

Prior to purchasing the system,

Buck sent two of his most critical

resins to Davis-Standard’s techni-

cal facility in Pawcatuck, Conn.

Davis-Standard was able to test

the resins on a full-scale sheet line,

successfully running both resins in

various thicknesses and to the ex-

acting quality requirements.

17

Extrusion 2/2016

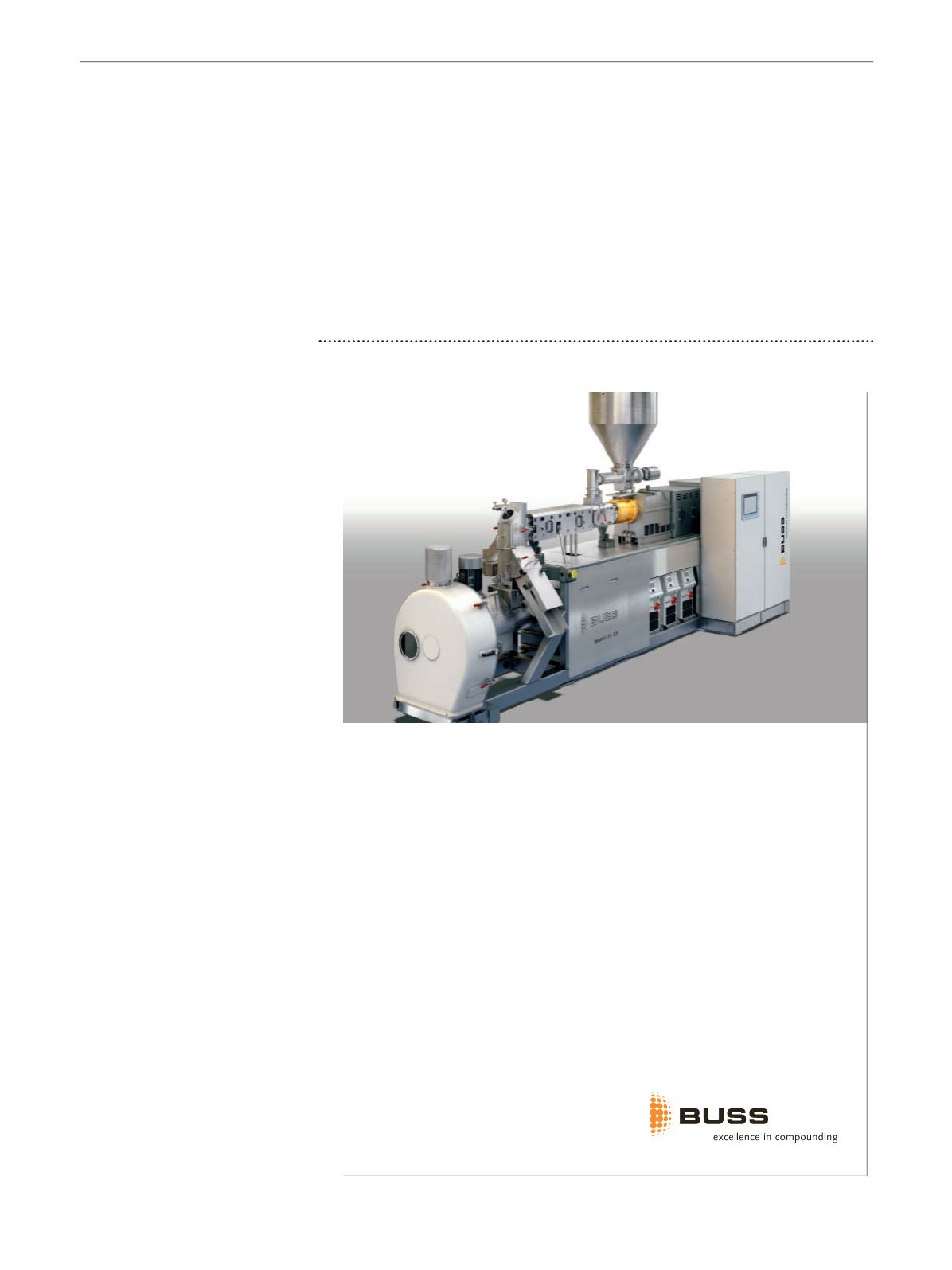

Economical PVC compounding redefined

BUSS Kneader series

quan

tec

®

G3

The specialists in heat and shear sensitive compounding are

setting new benchmarks for quality and productivity.

quan

tec

®

G3

– an ongoing success story in the third generation

>

More cost effective due to increased throughput

>

More flexible due to a larger process window

>

Improved plant availability due to minimal product

changeover times

Buss AG

Switzerland

www.busscorp.comquan

tec

®

85

G3

-14 C

Davis-Standard, LLC

www.davis-standard.comAdvanced Plastic Extrusion,

LLC (Apex)

www.apex-extrusion.comHigh-End Sheet

Operation launched

DuPont Performance Materials (DPM)

www.dupont.comDuPont Performance Materials inves-

tiert in Kapazitäten für die Herstellung

von Zytel

®

HTN PPA am deutschen

Standort Hamm-Uentrop. Die derzeit im

Bau befindliche Anlage wird die erste

Produktionsstätte für diese Hochleis-

tungspolyamide in Europa sein und den

Betrieb im Sommer 2016 aufnehmen.

Produktionskapazitäten in Europa

Grund für die Erweiterung der Produkti-

onskapazitäten für Zytel

®

HTN ist die

weltweit wachsende Nachfrage nach

diesem Werkstoff in den Bereichen Au-

tomobil, Elektrik und Elektronik sowie

Unterhaltungselektronik.