24

Extrusion International 4/2016

EXTRUSION INNOVATION

Lower melt temperature,

less energy consumption

and cost reduction

At this year’s plastics trade fair, battenfeld-cincinnati will be introducing a newly developed

series of high-performance single screwextruders: the solEXNG (NG=Next Generation) series.

Developed on the basis of the proven solEX series, this new generation features a completely

newprocessing unit which offers amultitude of advantages, such as a lower melt temperature

and energy costs reduced by up to 15%.

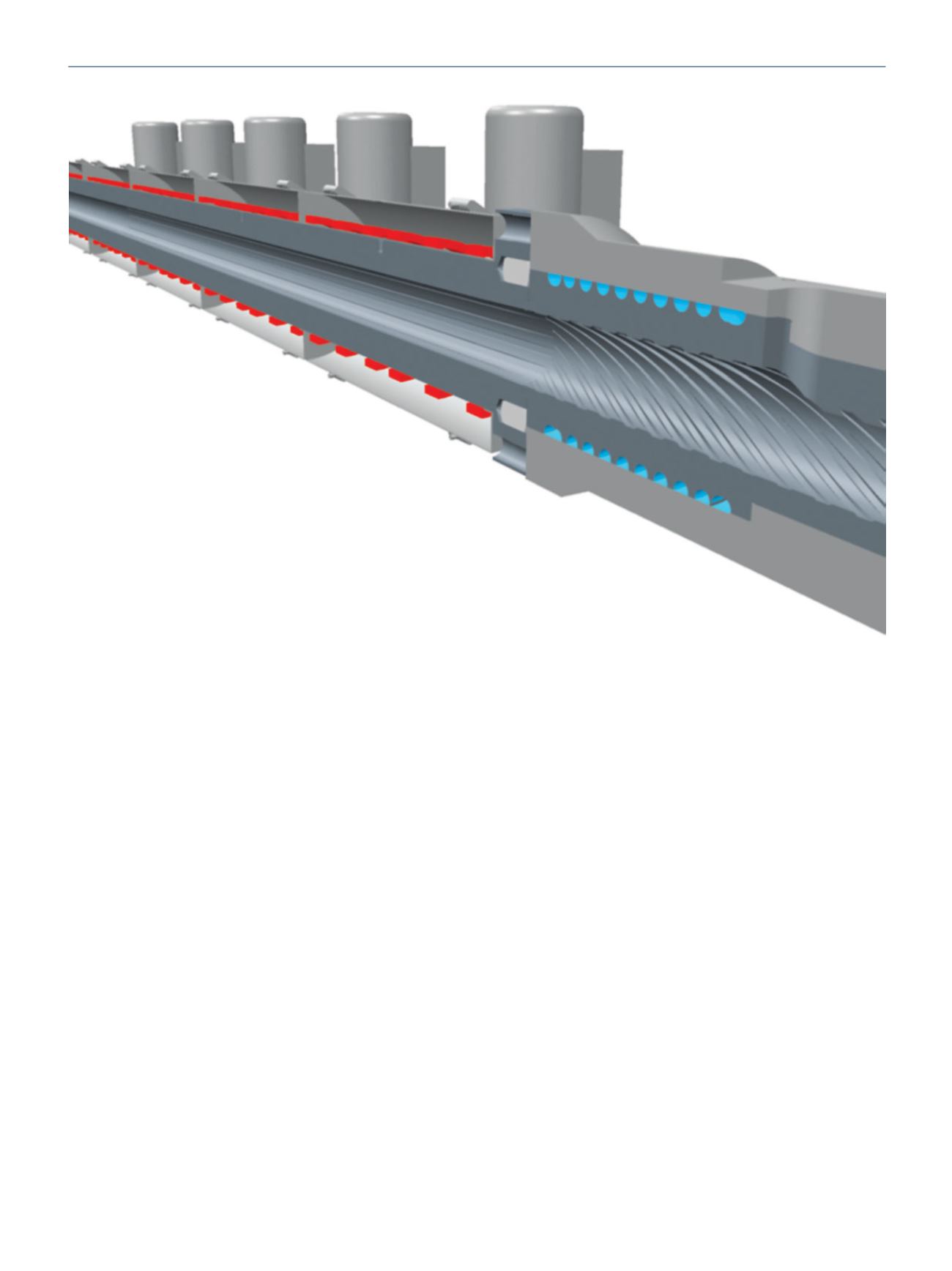

This picture shows a cross-section of the barrel to illustrate the internal

design of the new processing unit. The various differently shaped

grooves in the processing unit are designed to meet the specific

requirements of each section

(Schematic representation: battenfeld-cincinnati)