Extrusion International 2/2016

27

www.kraussmaffeiberstorff.comThe TecDay participants were fascinated by the unique

performance of the ZE 65 BluePower Torque twin-screw

extruder used for processing polyamide 6 with a 30 percent

glass fiber content at a maximum output rate of 2,500 kg/h

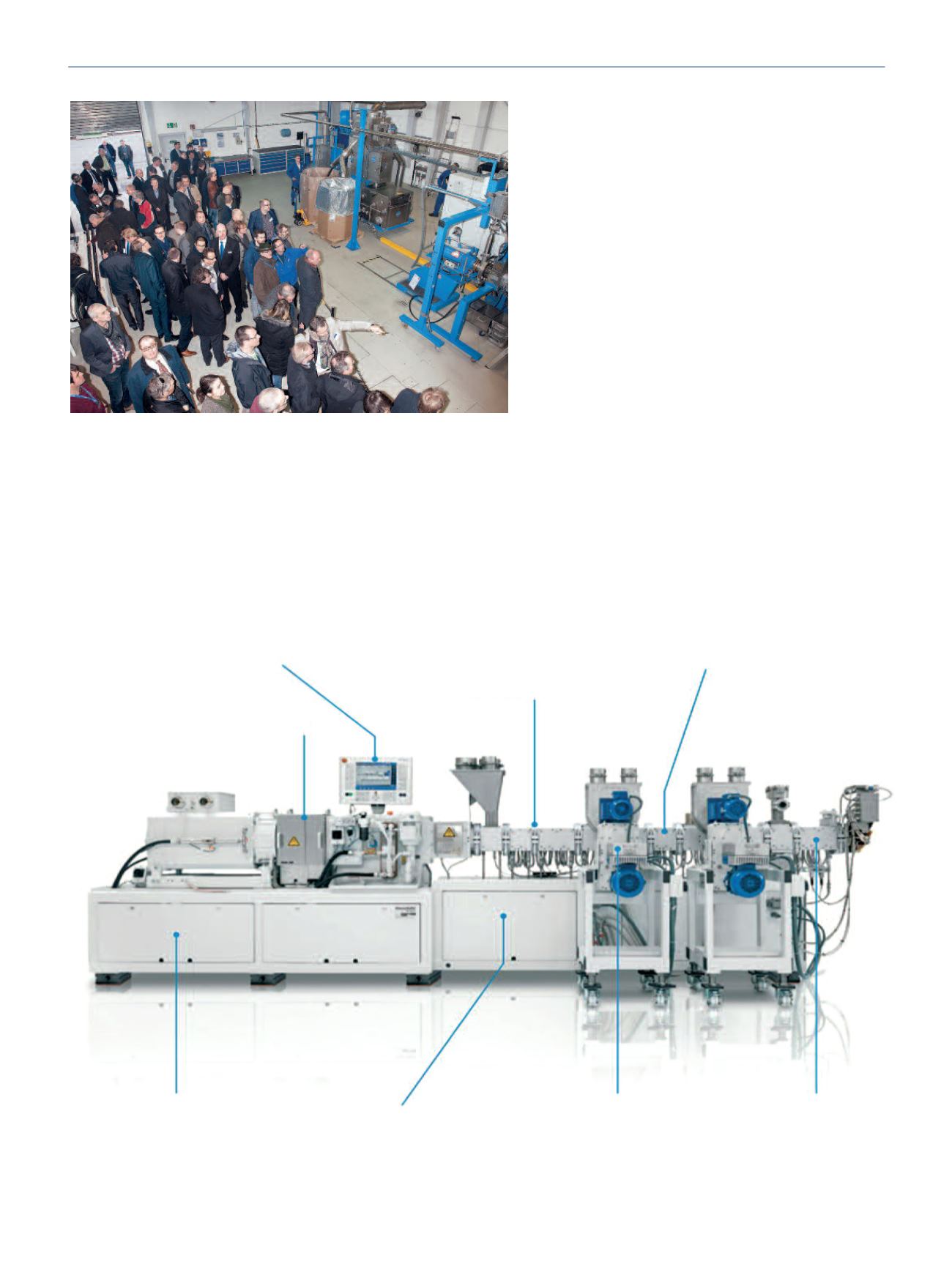

Advanced process control system (BPC-A)

Unparalleled ease of operation

Maximum modularity by 4- and 6-D barrels

Customized processing section

Perfect wear protection

Elliptical shoulder liners

Substantial increase

Torque density of 16 Nm/cm

3

Effective cooling

Temperature control system

User-friedly base frame concept

Easy access

Increased free volume

OD/ID diameter ratio of 1.65

Enlarged and optimized

Side feeder

point optimization of the drive system, including water-

cooled threephase motor and high-efficiency gear unit,

with a completely redesigned processing section. As com-

pared to the previous ZE A UTX series, the ZE BluePower

features an increased OD/ID diameter ratio of 1.65, which

gives a 30% higher torque density of up to 16 Nm/cm³.

Innovative technology secures competitive edge

For national and international compounding companies

that plan investments in extrusion technology, the TecDay

offered an ideal opportunity to take a closer look at the ZE

BluePower series and the appropriate upstream and

downstream equipment. The KraussMaffei Berstorff ex-

trusion line was complemented by supplies from Braben-

der Technologie GmbH & Co. KG (loss-in-weight feeder), Cabot

Switzerland GmbH (masterbatch), DSM N.V. (polyamide 6),

EMDE Industrie-Technik (bulk material handling), Gala Kunst-

stoff- und Kautschukmaschinen GmbH (underwater pelletizer),

NERAK GmbH Fördertechnik (elevator conveyor), PPG Industries

Fiber Glass B.V. (glass fibers) and Simar GmbH (bulk material

handling).

addition to numerous technical innovations, the overall concept

convinces by unparalleled performance, high cost-effectiveness

and increased energy efficiency,” says Ralf J. Dahl.

Increased free volume and enhanced torque density

The new ZE BluePower twin-screw extruder series is character-

ized by numerous innovative features in terms of energy effi-

ciency and process engineering. This series combines operating