Extrusion International 1/2016

20

even flexo printing to be transformed into the final

product. Designing and manufacturing 100% excel-

lence of the made in Italy.

After taking over the Dolci Extrusion & Bielloni com-

pany, operating since last year as AMUT DOLCI BIEL-

LONI, AMUT GROUP is able to offer to its customers

also flexible packaging solutions:

- cast and blown lines for multilayer films, in parti-

cular blown lines up to 9 layers for barrier, technical,

medical and lamination films, and cast lines for

stretch, diapers, PP, breathable and masking films;

- single, tandem or multiple stations coating lines;

- printing machines with up to 10 colours gearless

flexo presses;

- solventless or multisystems laminating machines;

- high speed and fully automatic slitter rewinders.

www.amut.itLocated in a strategic position between North and Central

America, Mexico is among the worlds’ major emerging econo-

mies. The Mexican market has shown a strong dynamism in the

recent years and is very open to foreign business and invest-

ments. In particular, the automotive field, the automotive mar-

ket and associated activities are among the most important and

competitive in the world.

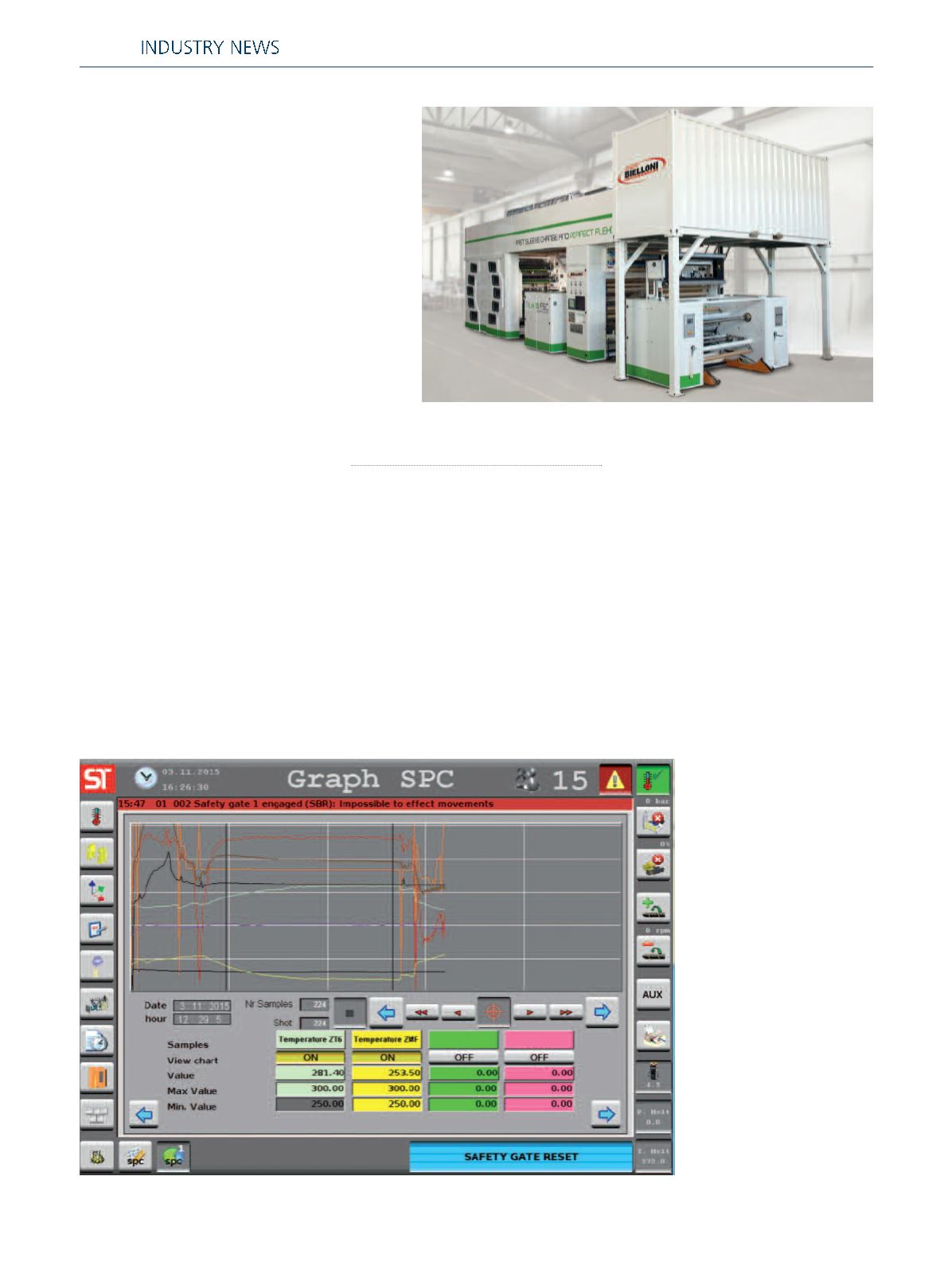

Always aware of market developments and trends, ST has noti-

New success in Mexico

ced the great growth potential of the country for a long time

and has undertaken a targeted commercial action that has led

to the sale of several plants, not least that of the recently tested

blow moulding machine model ASPI 150.2 with 3d suction tech-

nology. Although the suction technology is already present in

Mexico, a group of great global importance for the automotive

sector has decided to invest in the quality of ST’s blow moulding

machine.

The machine in question,

with a 70 mm extruder and a

2 lt head, presents the main

features of ASPI blow moul-

ding machines: accessibility,

flexibility, simplicity and preci-

sion as well as a technologi-

cal level that ensures high

performance.

These characteristics gene-

rate immediate advantages

such as: reduced scrap, the

possibility of processing ma-

terials up to 350°C, the pos-

sibility to produce parts with

three-dimensional

shapes,

even very complex and pro-

nounced, with a considerable

energy saving.

www.st-blowmoulding.com