27

Extrusion International 4/2016

PET SHEET EXTRUSION

high polymer surface exchange rate under

vacuum in the MRS section, a vacuum level

of only 25 bar is required in order to achieve

100 % moisture extraction. Another effect

of the extremely high polymer surface area

exchange rate under vacuum is the excellent

extraction of volatile contaminants. The sys-

tem achieves the requirements of both the

FDA and EFSA without restrictions PET sheet

made on the MRS extruder is therefore suit-

able for food contact applications whatever

input material is used and without any pre-

treatment of the input material.

The Gneuss Processing Unit includes also the

unique Gneuss Rotary Melt Filtration System

for the efficient removal of solid contami-

nants with fine filter elements even on post-

consumer bottle flake. The Gneuss Online

Viscometer ensures a consistent, defined IV

value of the polymer thanks to the intelli-

gent control system and is an extremely use-

ful tool for quality monitoring and control.

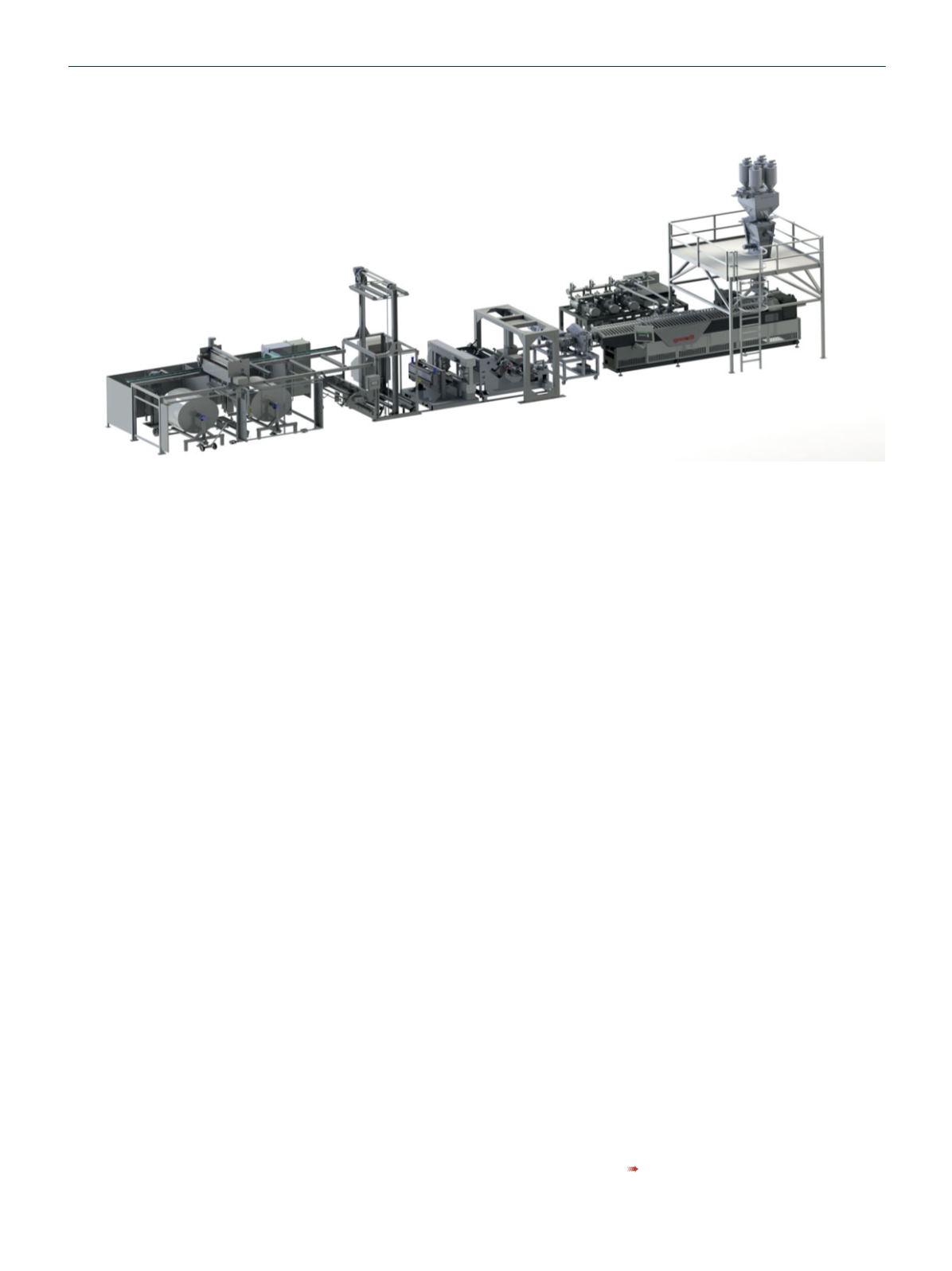

Gneuss offers complete lines including the up-

and downstreamcomponents fromthemate-

rial dosing system to the die, roller stack and

to the winder, which are all tailored to the ex-

act requirements of the individual customer.

As Dr. Carl-JürgenWefelmeier (Manager Busi-

ness Unit Film and Sheet) was pleased to in-

formus: “We are very proud that we can offer

turnkey PET sheet extrusion lines – from the

project engineering to After-Sales-Service”.

Gneuss can offer individual systems, whether

it be for the replacement of existing, conven-

tional extruders in existing lines with Gneuss

Processing Units or the design, supply and

commissioning of a complete new PET sheet

line. In each case, sheet with a high transpar-

ency and gloss, extremely low haze and low

yellowness with good thermoformability

can be made with great efficiency.

The complete sheet extrusion lines are highly

flexible with regard to the input material and

with regard to the sheet which can be made

on them, inlcuding even sheet for optical ap-

plications.

www.gneuss.comWithin the packaging industry, the use of

PET sheet is on the increase and the use of

recycled material is likewise on the increase.

Whether the PET sheet is used for transpar-

ent packaging for food (trays or tubs for

fruit, vegetables, meat, cookies etc.) or for

non-food (such as blister packaging) it is al-

ways important to take account of the par-

ticular properties of PET and it is exactly this

which Gneuss has done.

With the Multi Rotation System (MRS) Ex-

truder, Gneuss has developed the only ex-

truder specifically designed not only with

the material PET in mind, but with the repro-

cessing of PET. With the MRS extruder Gne-

uss offers a processing unit which enables

PET to be extruded cost effectively, without

any pre-drying or crystallisation. This applies

both to the processing of both virgin and

post- consumer bottle flake with a residual

moisture level of 1 % and in some cases

more. The extruder will also easily handle

PET / PE scrap (laminated sheet) andmixtures

of PET and PETG. Thanks to the extremely

Gneuss Thermoforming Sheet Line

Increased Flexibility and Food

Contact Certification

Machinery manufacturer from Bad Oeynhausen (Germany)

delivers complete, tailor-made PET Sheet Lines

In the worldwide growth industry of PET packaging sheet,

Gneuss has installed over 20 tailor-made sheet lines over the

last few years. Gneuss´ customers find the extreme flexibility of

the Gneuss Processing Unit (GPU), consisting of MRS extruder,

Rotary Filtration System, Online Viscometer and Control System

completely convincing when processing PET, whether virgin or

recycledmaterial andwithorwithout foodcontact requirements.