43

Extrusion International 4/2016

of post-consumer wastes. With the aid of the RecyClass

(www.recyclass.eu) programme, any manufacturer of

plastics packages can quickly and easily check whether his

package is recycling-friendly. Here it is particularly impor-

tant to dispense with fillers like chalk in PE and PP pack-

ages as far as possible, avoid plastics-paper composites,

use pigmentation in moderation and make sure that the

density of all products is well clear of 1 g/cm³ so that sepa-

ration on the basis of density is possible.

At the same time, efforts are being made in the indus-

try to develop reutilisation strategies for mixed wastes.

Trenntechnik Ulm GmbH is pursuing a very exciting ap-

proach here in developing a chemical separation process

for PE/PA composite films and building a unique produc-

tion plant with a capacity of 10 tonnes per day. The end

products of the separation process are a polyamide com-

parable with virgin material and a polyethylene that is

pigmented directly with soot, i.e. a carbon black master

batch in a particularly pure form. As stressed by Manag-

ing Director Wolfgang Zacherle, there is a suitable sol-

vent and separation agent for every plastics composite,

so there are no obstacles to an extension of this process

to other composite products.

Summary

Although recycling is a much-discussed topic today and is

also very much alive in many projects in the plastics indus-

try, experts are repeatedly confirming that, by compari-

son with other sectors, too little waste material is used

instead of virgin material. Across Europe, 50 per cent of

metal scrap is returned to the steelmaking process, and

the same applies to the paper industry, where 50 per cent

of old paper and board is used in the production of new

paper and board. For glass, at 33 per cent, the figure is a

little lower, but still very high compared to the quantities

that are recycled in the plastics sector. For in the plastics

sector, only about 4 per cent of reprocessed waste plastics

are used instead of virgin material in the fabrication of

plastics products. The plastics sector is of course a young

industry overall. Plastics only became widespread in the

1950s, and reutilisation strategies for waste plastics were

only introduced in 1990s, yet both the collection systems

and technical feasibility have developed enormously in

the intervening period. Anyone wishing to find out about

these new technical solutions can do so at K 2016, the

world’s No. 1 trade fair for the plastics and rubber indus-

try, from 19 to 26 October in Düsseldorf. Numerous ex-

hibitors are presenting machines and plant for processing

and recycling, for pure-grade wastes as well as for mixed

wastes and wastes of rubber.

It can therefore be assumed that recycling rates will contin-

ue to rise in the years to come, as there is strongdemand for

recyclate for both environmental and economic reasons.

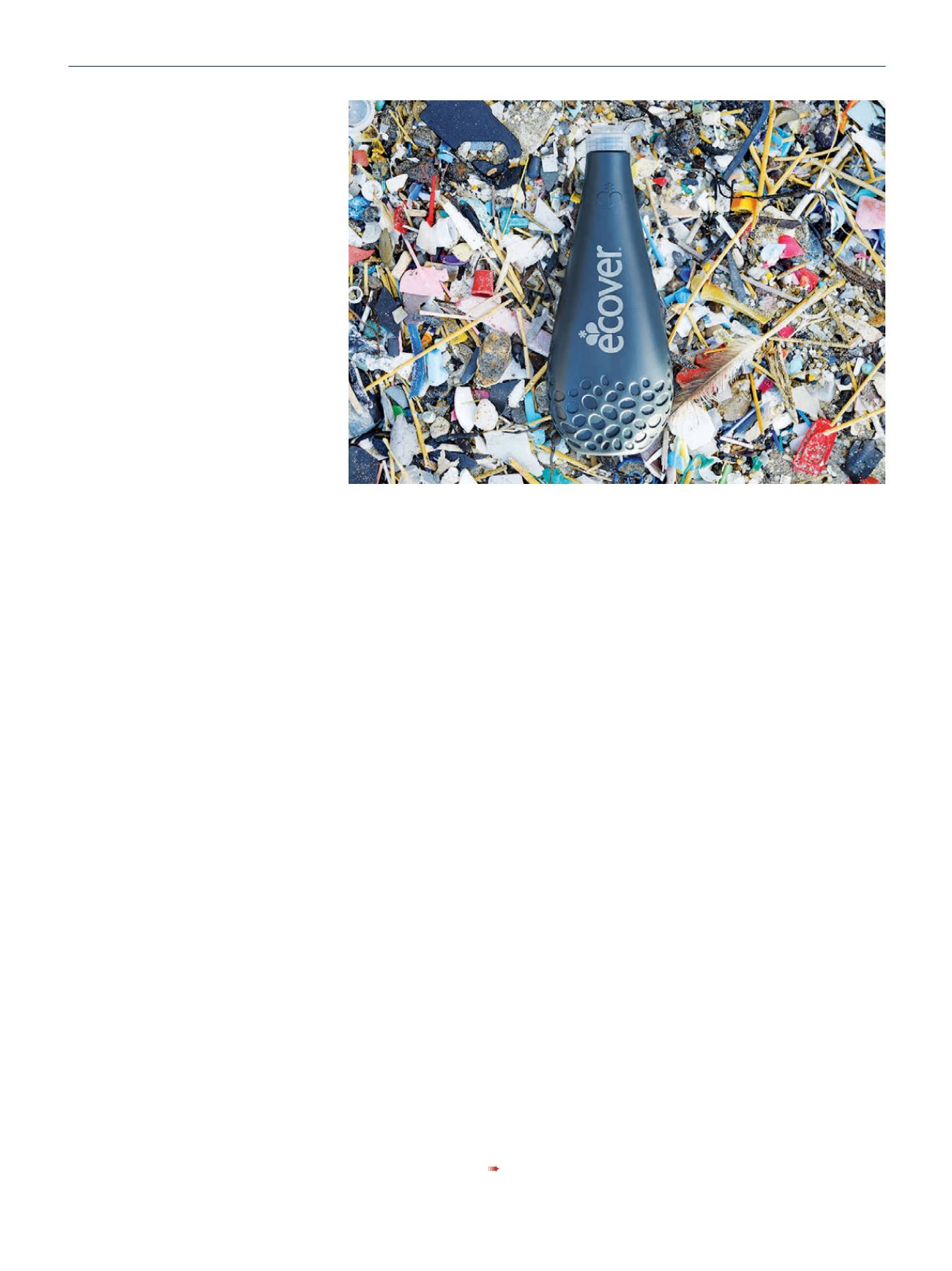

Marine litter, i.e. the pollution of the seas with wastes, has

internationally highlighted the irresponsible treatment of

wastes particularly in newly industrialised countries and

lent added strength to the demands of other consumers

for the sustainable treatment of resources. Model projects

like the Ocean Bottle are not only very interesting exam-

ples, but also help to raise awareness of the subject among

the general public and, above all, consumers. For the pro-

duction of this Ocean Bottle, Ecover Belgium N.V. enlisted

the services of fishermen in Britain, France and Belgium to

collect bottles from the sea. 10 tonnes of waste was accu-

mulated within a year, and the PE fraction from this was

recycled into new PE dishwashing detergent bottles.

www.k-online.comFor the extrusion blow-moulded

dishwashing detergent bottle made

of polyethylene, Ecover Belgium N.V.,

manufacturer of ecological cleaning

agents, uses plastic wastes gathered by

fisherman from the sea. Image: Ecover