39

Extrusion International 4/2016

From sorters and washing plant manufacturers to downstream

producers, fillers and brand owners, representatives from the

entire PET recycling value chain were present at the EREMA

headquarters. The expectations of the interested attendees

were high as, further to the currently low oil price, the conclu-

sion may be drawn that PET recycling is not profitable at the

moment. “In my experience with customers, the reason why a

producer decides in favour of a major investment in a recycling

solution is based on a broad-sighted, entrepreneurial approach.

Only those companies which are willing and able to adapt will

remain in the constantly fluctuating plastics industry in the long

term. Thanks to the collaboration with SIPAwe make it possible

for plastics producers to show the necessary flexibility,” says

ChristophWöss, Business Development Manager for Bottle Ap-

plications at EREMA. The cooperation between two big players

in the plastics industry made it possible to develop a direct pro-

cessing solution which stands out through better preform qual-

ity characteristics when using rPET.

The food contact compliant melt produced by VACUREMA

®

runs when hot and thus without the otherwise common, in-

termediate cooling stage in pellet production directly into

the XTREME production process developed by SIPA to make

preforms in a single step. The benefit of this direct process-

ing, therefore, is an enormous boost in energy efficiency plus

considerably lower thermal damage to the PET material. En-

rico Gribaudo, SIPA General Manager, notes: “We are proud

to have developed such a sustainable product together with

EREMA. Sustainable in the sense of the company and sustain-

able in the sense of the environment. Moreover, the process-

ing gives you unrivalled benefits in logistics. XTREME RENEW

not only saves space, CO2 and energy, it also reduces costs.”

1.2 million tonnes of PET recycled so far

worldwide with VACUREMA

®

technology

Some 1.2 million tonnes of PET are already recycled every

year around the world with VACUREMA

®

technology for end

products such as preforms for the beverage industry as well

as for thermoforming sheet, fibres, strapping, etc. This shows

that recyclers and producers can count on flexibility in their

production processes to react to fluctuating economic fac-

tors. The claim of adaptability applies likewise to the highly

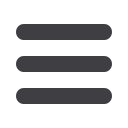

www.erema.atPresentation of XTREME RENEW: Gianfranco Zoppas, Chairman

SIPA/Zoppas Industries; Manfred Hackl, CEO EREMA; Klaus

Feichtinger, CEO EREMA; Marc Jacobs, CEO marcjacobsconsulting;

Christoph Wöss, Business Development Manager Application

Bottle EREMA; Enrico Gribaudo, General Manager SIPA

efficient MPR

®

which can be retrofitted to existing extrusion

lines. Decontamination, drying, dedusting and crystallisation

of different PET input materials take place in just one step.

As a result, the washed PET material is already food contact

compliant prior to extrusion. VACUREMA

®

technology offers

a very high degree of flexibility in PET recycling which is en-

hanced even further through the successful collaboration be-

tween EREMA and SIPA.

EREMA Group

The company EREMA Engineering Recycling Maschinen und

AnlagenGes.m.b.H., which specialises in the development and

production of plastics recycling systems, was founded in 1983.

Besides EREMA itself, the EREMA Group comprises the sister

companies 3S, PURE LOOP (January 2015) and UMAC (begin-

ning of 2016). With subsidiaries in the USA, China and Russia

plus around 50 local representatives in all five continents, the

EREMA Group has a reliable network to realise customised

recycling solutions for international customers. Around 480

people around the world nowwork for the Austrian company

group which is headquartered in Ansfelden near Linz.

SIPA. The PET Specialists.

For more than 30 years SIPA has specialized in complete man-

ufacturing lines for PET containers, including design, produc-

tion, filling, and packaging solutions. SIPA tailors technology

recommendations to customer needs based on unmatched

knowledge and experience of the entire PET process. Head-

quartered in Italy, the company can rely on 17 sales branches,

3 manufacturing facilities and 28 service centers for fast access

to service, parts, and expert engineering support.

The pivotal product from SIPA in the cooperation with EREMA

is the XTREME Preform Production System. In this process the

PET material is subjected to four times less pressure, which is

why preforms with significantly better key characteristics and

with up to 10 per cent less weight than in injection molding

production can be made.

MPR – Multi Purpose

Reactor complements

existing extrusion systems