18

Extrusion International 4/2016

COMPOUNDING

Compounding 4.0

Moving forward with AZO to the digital age with

networked processes, a comprehensive information

portal and the first Industry 4.0 components

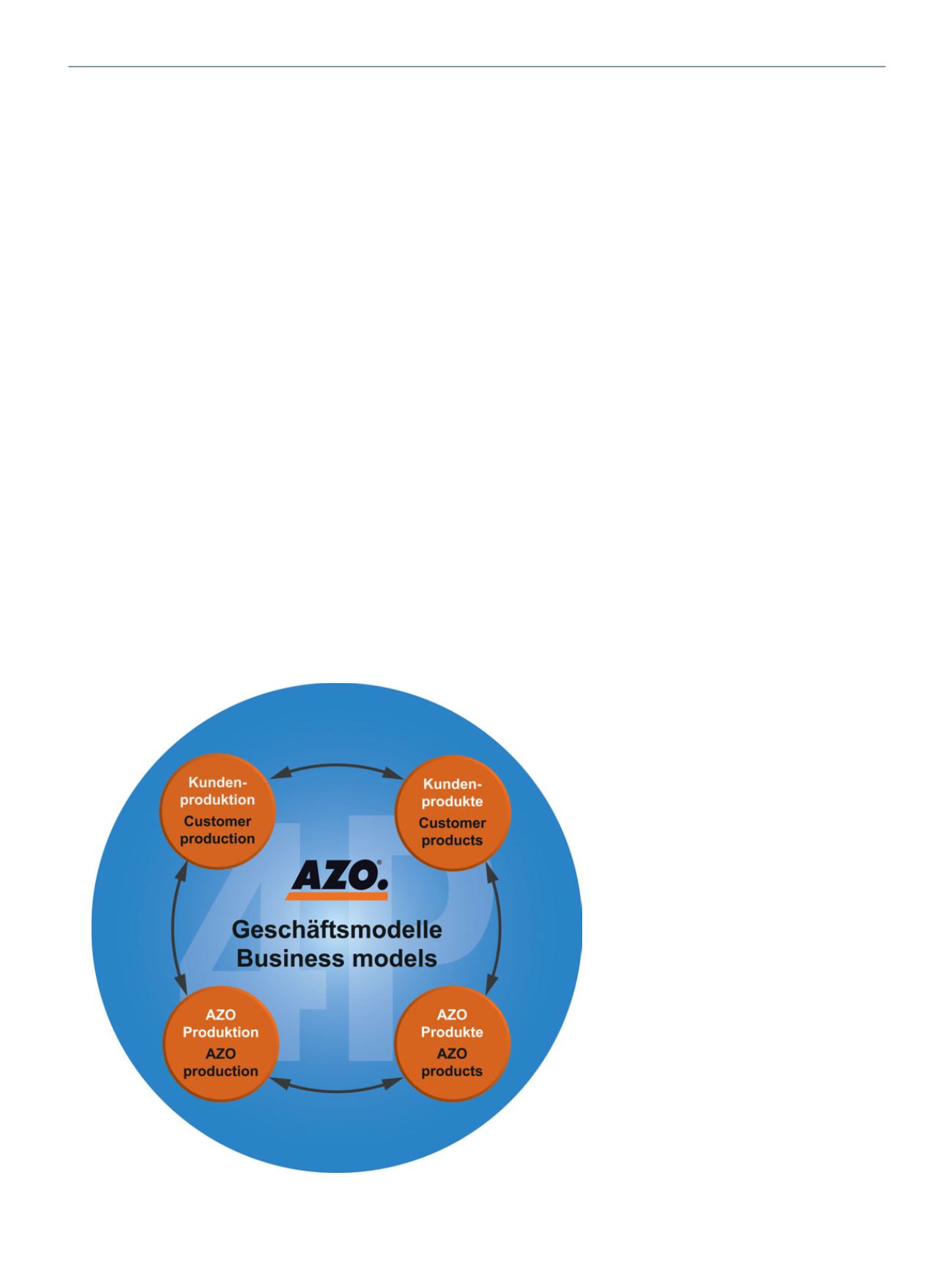

Pic. 1: AZO defines the 4P as a goal to implement Industry 4.0

In many companies Industry 4.0 (or

the Industrial Internet of Things) is

currently a work-in-progress that not

everyone is willing to tackle. The first

enterprising projects indeed demon-

strate what digitisation can lead to,

for example in the sectors of additive

manufacturing, virtual reality and

robotics. The plastics industry and its

customers in particular can have high

expectations.

However this work-in-progress still

appears chaotic to many and, above

all, huge inmagnitude. Where do you

start? If you want to build a house, a

really big one with all the latest gad-

gets, the very latest in technology,

a sophisticated energy concept and

– for the possibly still distant future –

accessible for disabled users, you will

know: it doesn’t happen overnight.

You need to allow sufficient time

just to give thorough consideration

alone, which of the dreams it is abso-

lutely essential to realise, which are

only maybes and which should not

be realised until a later date. Some

Digitisation will rapidly lead to added value for the plastics and plastics-manufacturing

industries. High time to take a systematic approach to tackling the potential offered by

Industry 4.0 (or the Industrial Internet of Things) – to follow the example set by AZO, the

plant engineering company. The result has already seen several concrete projects, based on

careful analyses and estimates of potential, where Industry 4.0 and the ensuing opportunities

become reality.