12

Extrusion International 4/2016

INDUSTRY NEWS

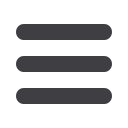

ST BlowMoulding and DuPont consolidate their partnership

On June 24th a major inaugural ceremony was held at the

European Technical Center of DuPont in Meyrin, Geneva.

The ceremony, marking the culmination of eight years of

cooperation between the two companies, was attended by

Pierre Maudet, Minister for Economy and Security for Ge-

neva; Daniel Loeffler, Director at Economic Development

Office for Geneva; Rolf Gobet, Director of the Office for the

Promotion of Industries and Technologies (OPI); as well as

members of the press .

The ceremony was held to inaugurate the launch of a new

machine for the blow molding of plastics, model ST ASPI

SECO that the company ST Blow Moulding, with a produc-

tion site in Stabio, in the canton of Ticino, has recently deliv-

ered to the research center of Meyrin.

The Meyrin site is the technological research and develop-

ment center of DuPont, a cutting-edge space in research and

technical innovation. For over 20 years now, the European

Technical Centre works for the development of applications,

such as, for example, blow molding air ducts, based on a col-

laborative approach.

This is the second blowmolding machine supplied by St Blow

Moulding, after the first delivered in 2010, and confirms the

strong partnership between the two companies.

The delivered blowmoulding machine model ST ASPI SECO is

suitable for the production of parts with materials in mono-

layer, coextrusion or SeCo (Sequential Coextrusion), in case

of need to produce items requiring different mechanical or

chemical properties in predefined areas, usually for the au-

tomotive industry.

The machine is equipped with two extruders of 60 mm, two

accumulator heads, respectively by 1 and 1.5 liter and a co-

extrusion head.

An application worth mentioning is definitely the 4WDS ra-

dial control system, integrated in this model of blow mould-

ing machine.

This system, based entirely on the experience and technical

knowledge of St Blow Moulding allows to obtain a uniform

wall thickness, also for parts of more complex shape and dif-

ficult to be manufactured.

Furthermore, the ST ASPI SECO blow moulding machine is

the only model of the ST ASPI range equipped with a shutter

that allows a perfect control in the transition from one mate-

rial to another, during the sequential production.

www.st-blowmoulding.comComposites Germany Pavilion to make its debut

The industry association Composites Ger-

many will host its first ever group stand at this

year’s COMPOSITES EUROPE (29 November

– 1 December in Düsseldorf). The umbrella

organisation of the German fibre-reinforced

composites industry, whose members include

the AVK, CCeV, CFK-Valley Stade and the

VDMA Working Group Hybrid Lightweight

Technologies, will host a 350-square-metre

group stand featuring a total of 18 member

companies.