Extrusion International 3/2016

37

By reducing the cooling water temperature of the mould, a

shorter cycle time and subsequently a higher production out-

put can be achieved. If the water temperature sinks below the

dew point of the ambient air, the moisture in the air will con-

densate on the surface of the mould. To avoid this condensa-

tion in facilities located in hot and humid climate zones,

process engineers of manufacturing plants tend to increase

the water temperature above the ambient dew point of the

air. This standard procedure has a crucial disadvantage - the ef-

ficiency confines the effectiveness: increasing the cooling

water temperature extends the cooling time of the item in the

mould, thus reducing productivity and profit (rule of thumb:

1°C increase in cooling water temperature = 2% reduction of

productivity).

In many cases a longer cooling time increases the crystalliza-

tion rates in the moulded plastic resulting in inferior product

quality. Furthermore, condensation on the mould leads to pos-

sible water marks (“orange skin”) on the final product causing

rejects or low product quality.

Limitations of conventional technology

for mould dehumidification

A popular way of drying air for mould dehumidification is with

the adsorption system. This technology, that uses a desiccant

wheel for dehumidification, needs a comparatively high

amount of energy. The energetic inefficiency occurs due to the

use of large regeneration heaters, ventilators, motors and pre

and after cooling with the need for chilled water. Mould de-

humidification with the condensation technology, using a re-

frigerant system, is an alternative to the desiccant system. The

MSP (Mould Sweat Protection) units based on this technology

have been the backbone of Blue Air Systems for years. Many

MSP units have been in-

stalled in facilities world-

wide. Thanks to their

reliability and stability, these

units bring their full per-

formance even after many

years and allow a condensa-

tion-free production with the

optimal cooling temperature

in the mould. A disadvan-

tage of all dehumidifiers,

whether they operate on the

basis of adsorption or con-

densation drying, is that rela-

tively large cooling loads are

needed to pre-cool the am-

bient air.

In many cases, the chilled

water capacity of the facility

is not dimensioned suffi-

ciently to supply the neces-

sary cooling load of chilled

water. When investing in a

new dehumidification sys-

tem, besides the cost of the

Bernhard Stipsits, managing director of Blue Air Systems:

“The DMS units from Blue Air Systems guarantee condensation-free production

conditions in a closed system, even when using very low chilled water temperatures for

the moulds throughout the year, making you independent from ambient climatic

weather conditions. The MPSCS (Micro Processor Controlled Segment Condensation)

technology provides controlled parameters at all times, making sure the optimal

energetic conditions are automatically adjusted. What you get is higher productivity and

constant product quality in the production process at lowest possible energy

consumption. It’s time to start reducing our ecological foot print and the DMS is a huge

step in this direction!”

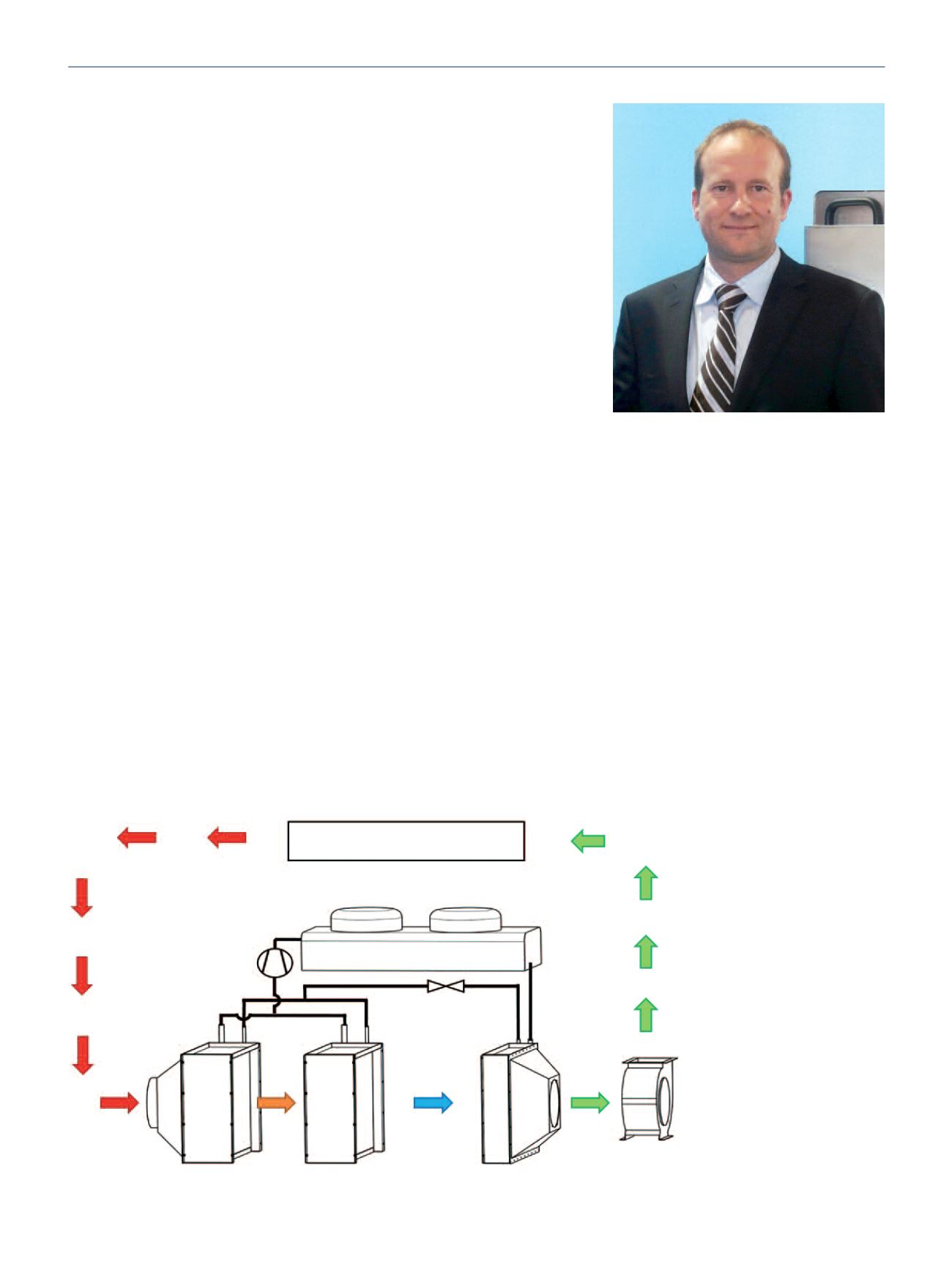

Functional Principle DMS (Dry Mould System): The process air is run in a closed loop, circulating back to

the DMS unit for pretreatment and dehumidification of the air to a 3°C dew point. The MPSCS (Micro

Processor Controlled Segment Condensation) technology guarantees perfect and consistent conditions

at the lowest possible energy consumption

Production Plant